VOLUTE DUO™ dewaters sludge with more than 90% inorganic content and achieves a cake dryness of 57%

Paint manufacturing in Poland

- Sludge dewatering press

- Paint manufacturing

- Dewatering inorganic sludge

- Paint manufacturing in Poland

Their problem

This plant is a leading paint manufacturer in Poland and is known worldwide. This high-density chemical sludge with a very high inorganic content (>90%) makes dewatering difficult, if not impossible, for conventional screw presses. With the VOLUTE DUO™ and its special twin screw design, AMCON can dewater even this high inorganic sludge and offer this client all the other benefits of a screw press.

AMCON’s solution

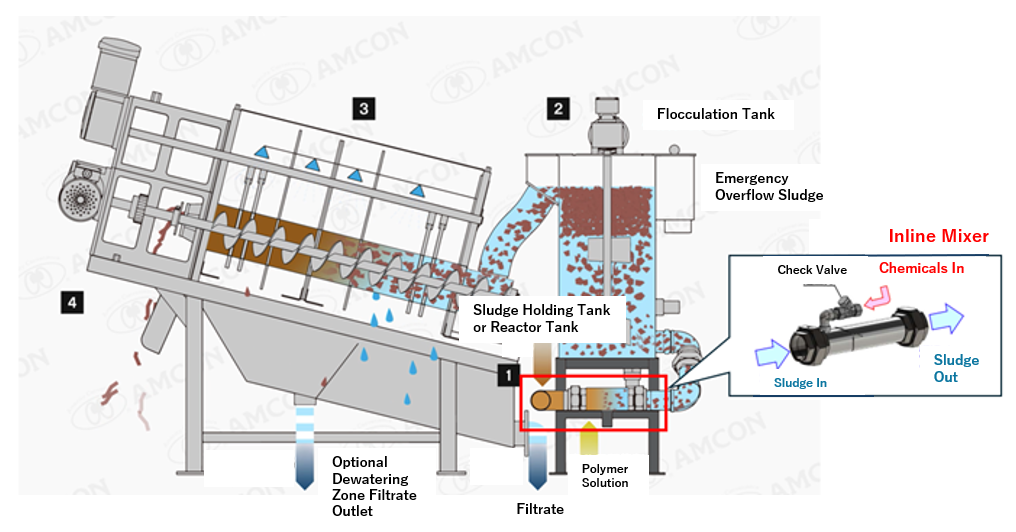

The VOLUTE DUO™ RVP-241 (HR-241) dewatered 30 m3 of sludge in 24-hour non-stop operation with a throughput of 41 kg-DS/h and a cake dryness of 56.9%. During operation, coagulation and flocculation were carried out by the in-line mixer to achieve the best quality flocs.

With its small footprint, very good cake dryness, filtrate quality, and low energy consumption, the VOLUTE DUO™ can now be used in this type of industry where conventional screw presses encounter many challenges.

In addition, by adopting an in-line coagulation system using an inline mixer, the unit was able to form strong flocs, achieving a high suspended solids (SS) recovery rate.

An inline mixer is a device that enables effective injection and mixing of chemicals within the sludge or wastewater that flows directly into the piping. By mixing the chemicals in the piping upstream of the flocculation tank, it promotes more effective and higher-quality floc formation. Additio

With its excellent dewatering performance, compact design, and energy-efficient operation, the VOLUTE DUO™ is ideal for dewatering sludge with high inorganic and fibrous content, which has been a challenge for most conventional multi-disc screw press dewatering machines. Please feel free to contact us for more information.