Cost reduction by using a proper polymer!

Confectionary and retort-packed food plant in Japan

- Water treatment chemicals

- Food Beverage

- Operating cost reduction

- Confectionary and retort-packed food plant in Japan

Their problem

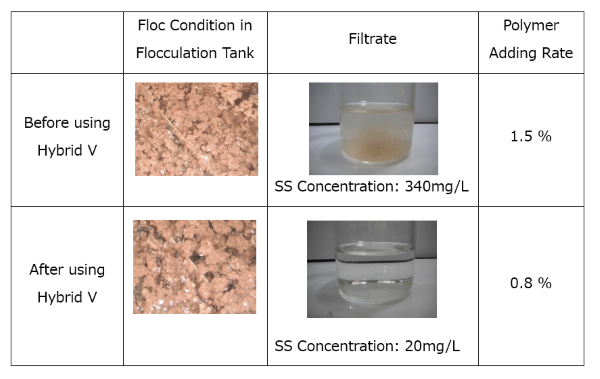

This nationally-known factory, famous for confectionery and retort-packed food, dewaters its waste activated sludge with VOLUTE™ EC-202 model. They had used powder polymer manufactured by another manufacturer. However our staff realized the flock is in poor condition when he visited their factory.

AMCON’s solution

When you use a wrong polymer, polymer adding rate tends to be higher in order to make flocks. Furthermore, in the first place, water content becomes worse due to unsuitable polymer to the sludge.

We would like our clients to use polymer that maximizes its dewaterability the best than unsuitable one. We selected the most suitable polymer from Hybrid V and offered the replacement of existing polymer.

The usage of our polymer that is suitable for their sludge made the polymer adding rate down and chemicals running cost reduced. Because the flock condition became well, solids capture rate also increased.