The Reasons for Ajinomoto Choosing VOLUTE™ Yet Again: Achieving Significant Waste Reduction and Stable Sludge Treatment

Ajinomoto Co., Inc. Tokai Plant

Mr. Kataoka (right) – Manufacturing Department, Utility Section

Mr. Tanaka (left) – Engineering Department, Mechanical Group

- Sludge dewatering press

- Pharmaceuticals

- Food Beverage

- Chemical

- Industrial waste disposal cost reduction

- Pilot test/rental

- User testimonial

- Ajinomoto Co., Inc. Tokai Plant

Mr. Kataoka (right) – Manufacturing Department, Utility Section

Mr. Tanaka (left) – Engineering Department, Mechanical Group - https://www.ajinomoto.com/?scid=pr_ot_pc_cojphead_global

Located in Yokkaichi City, Mie Prefecture, the Tokai Plant of Ajinomoto Co., Inc. has been a key production hub for the company since its establishment in 1962. The plant manufactures a wide range of products, including condiments like Hondashi®, amino acid-based sweeteners, pharmaceuticals, and chemical products. In 2020, a new state-of-the-art factory was added to the site, incorporating ICT and automation technologies to support end-to-end production and packaging of seasonings and supplements. The plant also actively engages with the local community through factory tours and educational outreach programs.

Issues Prior to VOLUTE™ Installation: Existing Sludge Dewatering System Reaching Its Limit

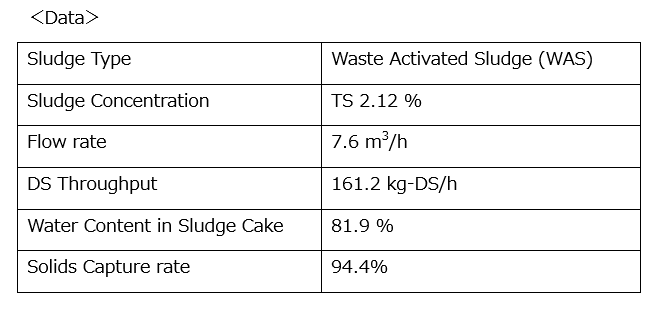

In FY2022, changes in wastewater composition and increased BOD load pushed the existing sludge dewatering equipment to its limit, resulting in several operational issues:

- Production had to be adjusted to limit wastewater generation

- Increased industrial waste disposal volumes

Prolonged period in which there was high moisture content, and difficulty dewatering. Such issues led to rising disposal costs and increased operational workload. To address the problem, Ajinomoto had begun contemplating our VOLUTE™ sludge dewatering press, which had already been introduced at several other Ajinomoto Group sites. A test installation was conducted using a rental unit to verify dewatering performance and capacity under actual operating conditions. The trial confirmed the expected improvements, leading to the decision for full-scale installation.

Post-Installation Results: Stable Operations and Cost Reductions

With the installation of our VOLUTE™ sludge dewatering press, the Tokai Plant achieved the following improvements:

- Eliminated the need for suppressing production just to limit wastewater generation

- Significantly reduced the volume of industrial waste

- Achieved stable moisture content in the dewatered sludge cake, improving processing efficiency

Successfully managed to showcase its expected treatment capability of 200kg-DS/h with stable operation.

Customer Testimonials

Mr. Kataoka and Mr. Tanaka, who are responsible for operating and managing the wastewater treatment plant, shared their experience:

“Thanks to the self-cleaning mechanism, the sludge treatment flow rate remains stable without decline. During the trial run and initial inspections after installation, support from AMCON was prompt, and we received helpful maintenance suggestions to ensure stable operation. We’re very satisfied with the overall after-sales service.”

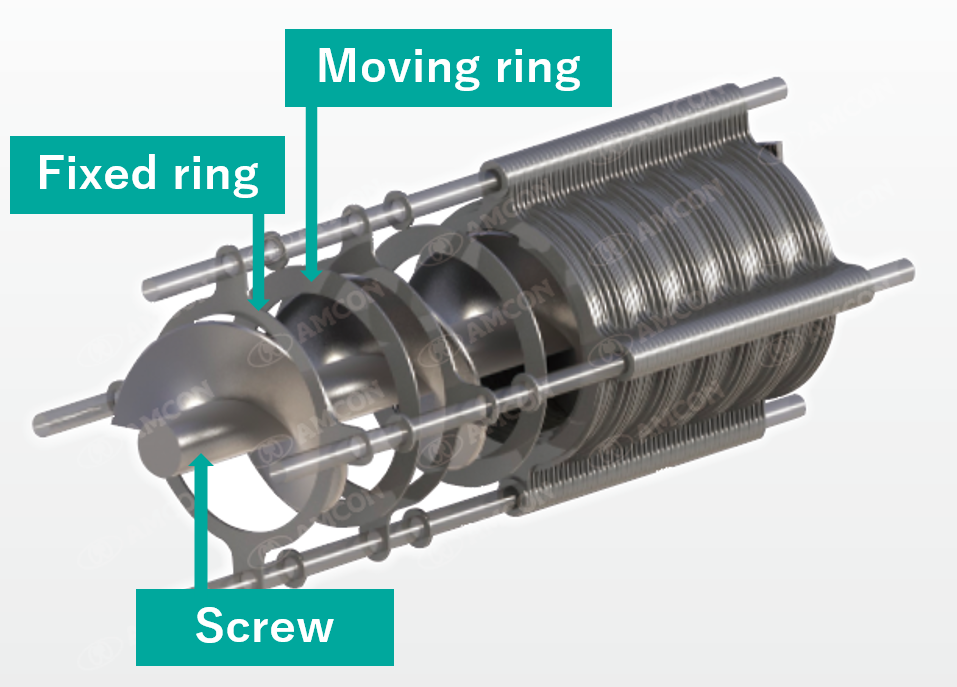

Our VOLUTE™ lineup features a filtration body consisting of alternating fixed and moving rings, through which a single screw transports and compresses the sludge. As the screw rotates, it causes the moving rings to shift, constantly cleaning the gaps and preventing clogging.

Are you looking to improve your sludge treatment capacity?

Concerned about the limitations of your current equipment?

We also welcome inquiries like:

- “Can we test the actual performance before deciding?”

- “Is this type of sludge suitable for the Volute™ system?”

At AMCON, we offer free sludge sample testing.

Please feel free to reach out to us for more information or to discuss your specific needs.