Achieved Reduction in Labor Costs and a Constant Stable Performance through Streamlined and Unmanned Operations.

All Nippon Airways Co., Ltd. Maintenance Center

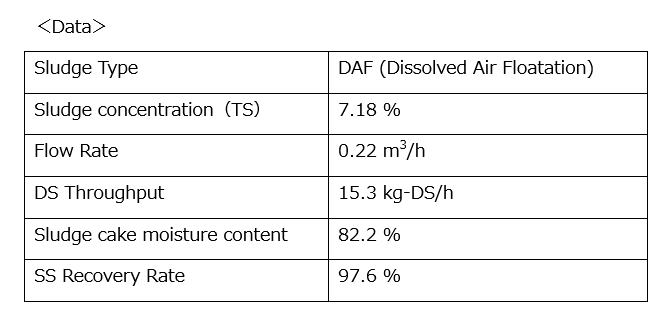

- Sludge dewatering press

- Airport facilities

- Operation management man-hour reduction

- Small footprint

- Improvement of work environment

- User testimonial

- All Nippon Airways Co., Ltd. Maintenance Center

At the ANA Maintenance Center, wastewater generated from aircraft maintenance was previously treated using centrifugal dewatering systems. However, it faced multiple challenges in terms of stability, operational efficiency, and sludge cake dryness – thus requiring a significant upgrade.

In February 2012, the Maintenance Center decided to adopt our sludge dewatering press for a more stable performance and to achieve better efficiency.

We have received substantial feedback from the operators at the wastewater treatment facility, highlighting the following benefits:

Operational Improvements

“Dewatering performance remains stable, so we no longer need to monitor it constantly, allowing us to focus on other tasks.

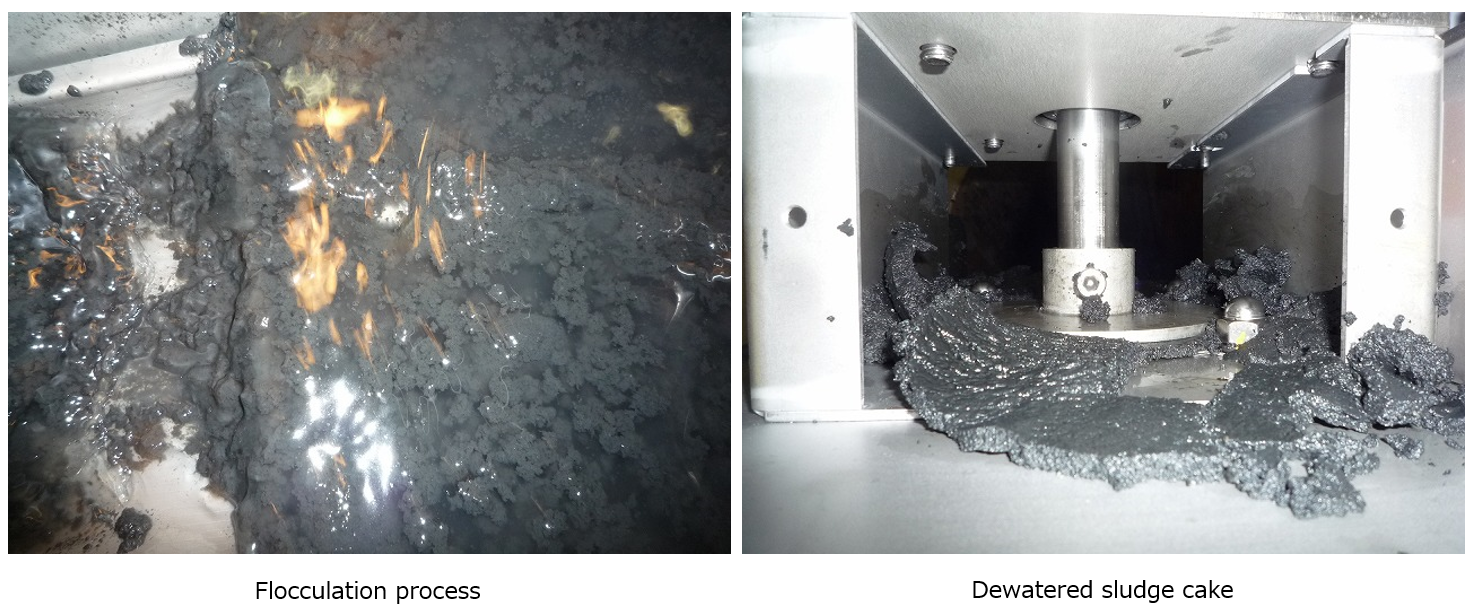

Once the flocculation and machine settings are adjusted, little to no re-tuning is needed. The unit runs quietly, has a simple structure, and is easy for anyone to handle.

Compared with the previous centrifuge, the moisture content has been reduced, resulting in significantly improved dewatering performance.” In addition, while the centrifugal dewatering machine required statutory self-inspections under labor safety regulations, the switch to the VOLUTE™ eliminated the need for such inspections.

Reduced Workload

“It has been over 13 years since installation, yet the equipment has rarely experienced failure, of which we are very much satisfied with. The fact that it can run almost unattended is indeed a major advantage.

Unlike filter press units, there is no need for labor-intensive cloth cleaning, which further reduces workload. The compact footprint and its consistent high performance make it an excellent solution for our needs.”

The introduction of our sludge dewatering press at the ANA Maintenance Center demonstrates how the system has earned long-term trust as a product that delivers both reduced labor costs and stable operation.

Are You Facing Similar Challenges?

- “We want to improve sludge treatment operations.”

- “We want to reduce operator workload.”

Would you like to observe real-life performance with an onsite test run?

Wondering if your sludge can be dewatered with our VOLUTE™?

AMCON offers free sludge sample testing—please feel free to contact us anytime.

For inquiries,contact us here.