ADVANTAGES

-

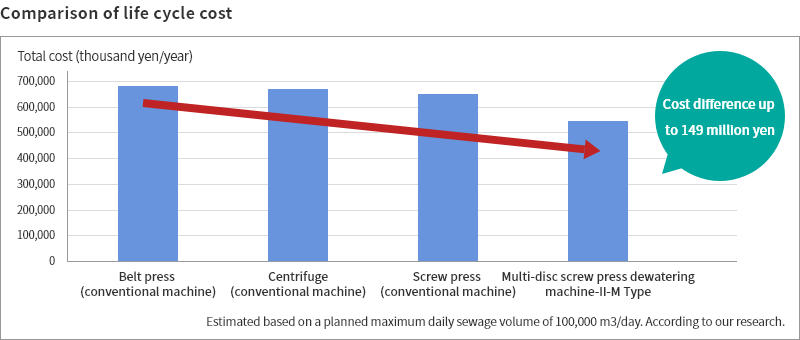

Reduced lifecycle costs

Reduced lifecycle costs -

Realize stable operation with control responding to concentration fluctuations

Realize stable operation with control responding to concentration fluctuations -

Overhaul & replacement of consumable parts performed on site

Overhaul & replacement of consumable parts performed on site -

Water-saving & Power-saving

Water-saving & Power-saving -

Low noise and low vibration

Low noise and low vibration -

Easy operation and easy maintenance

Easy operation and easy maintenance -

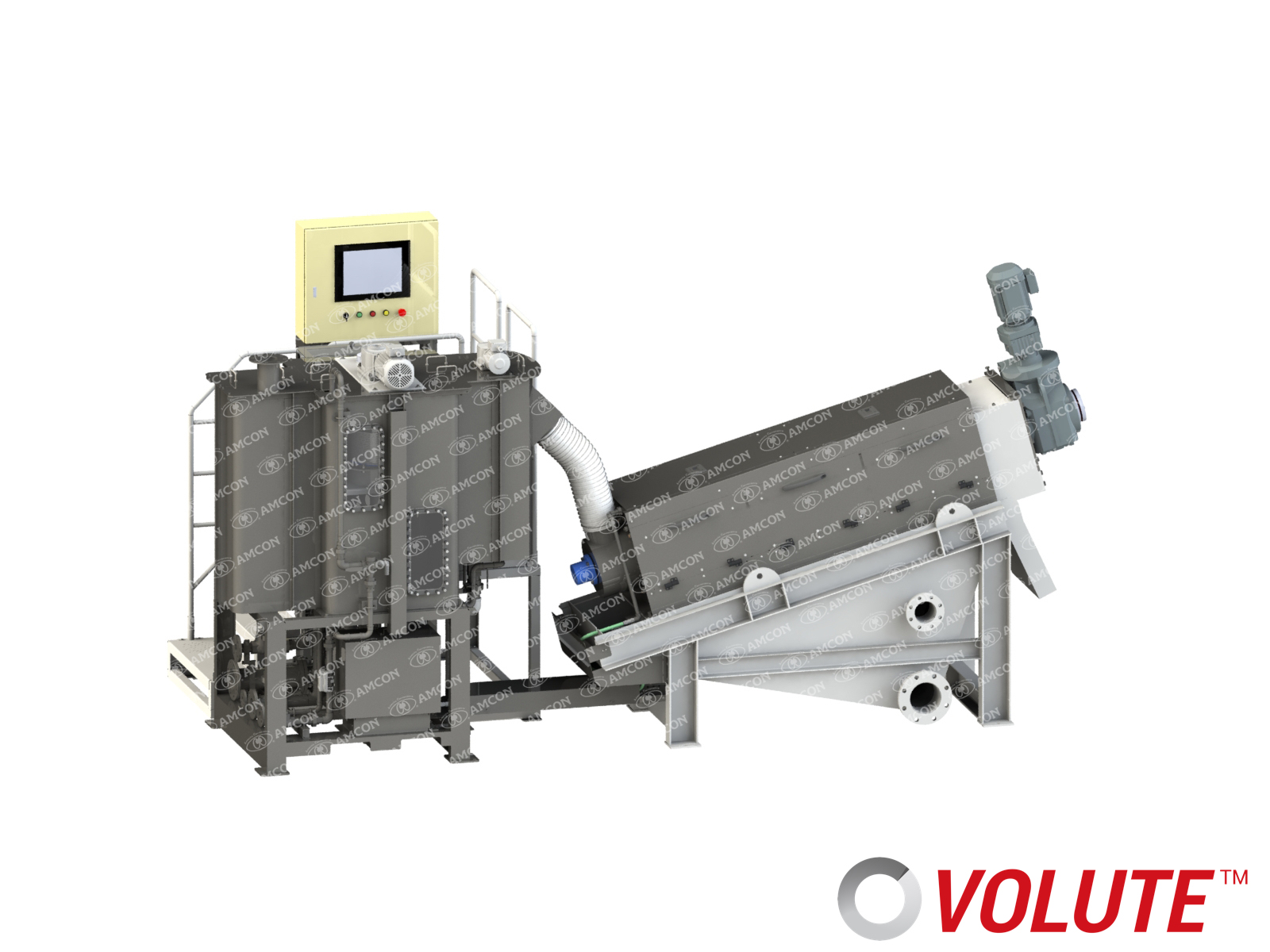

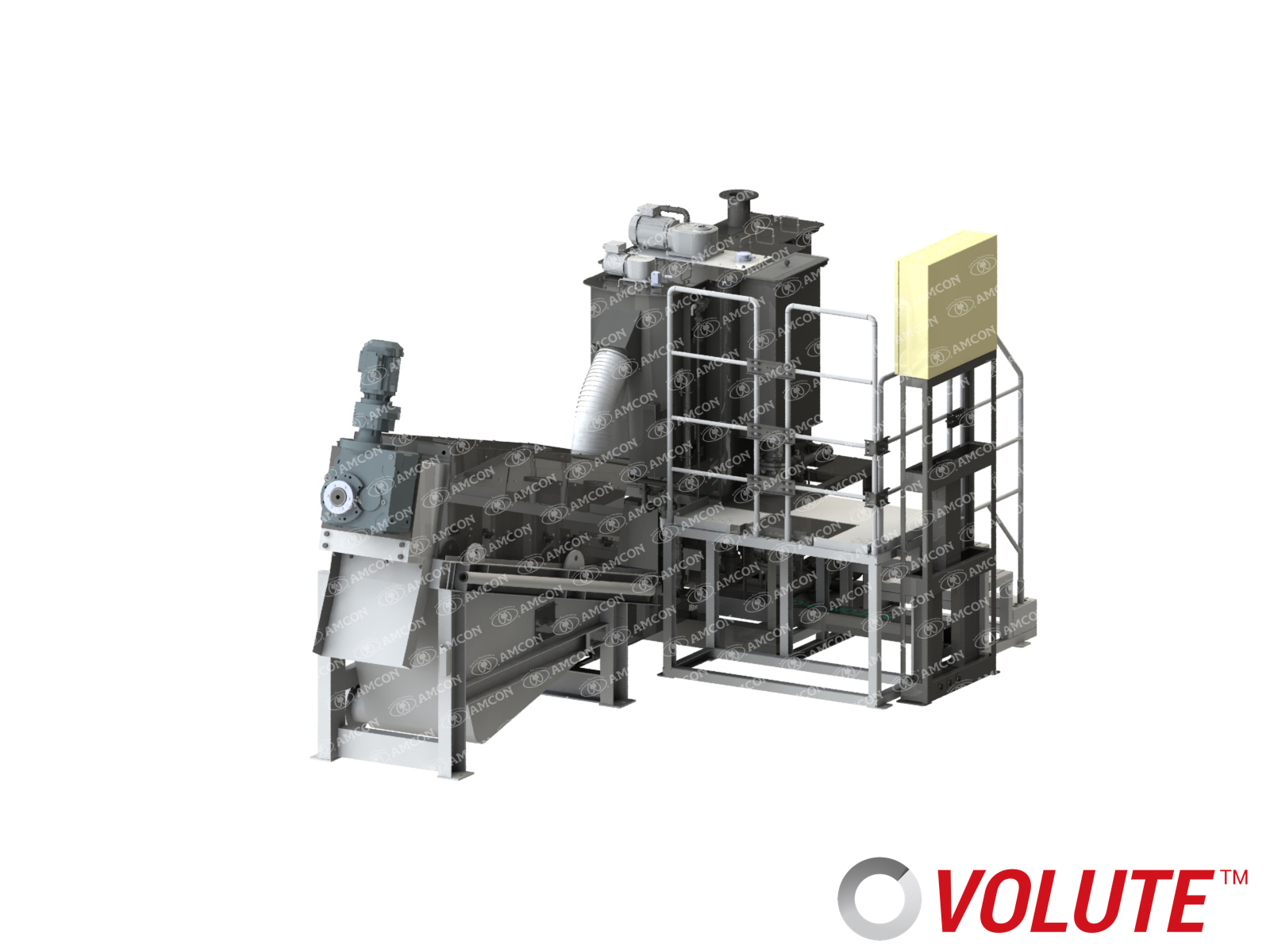

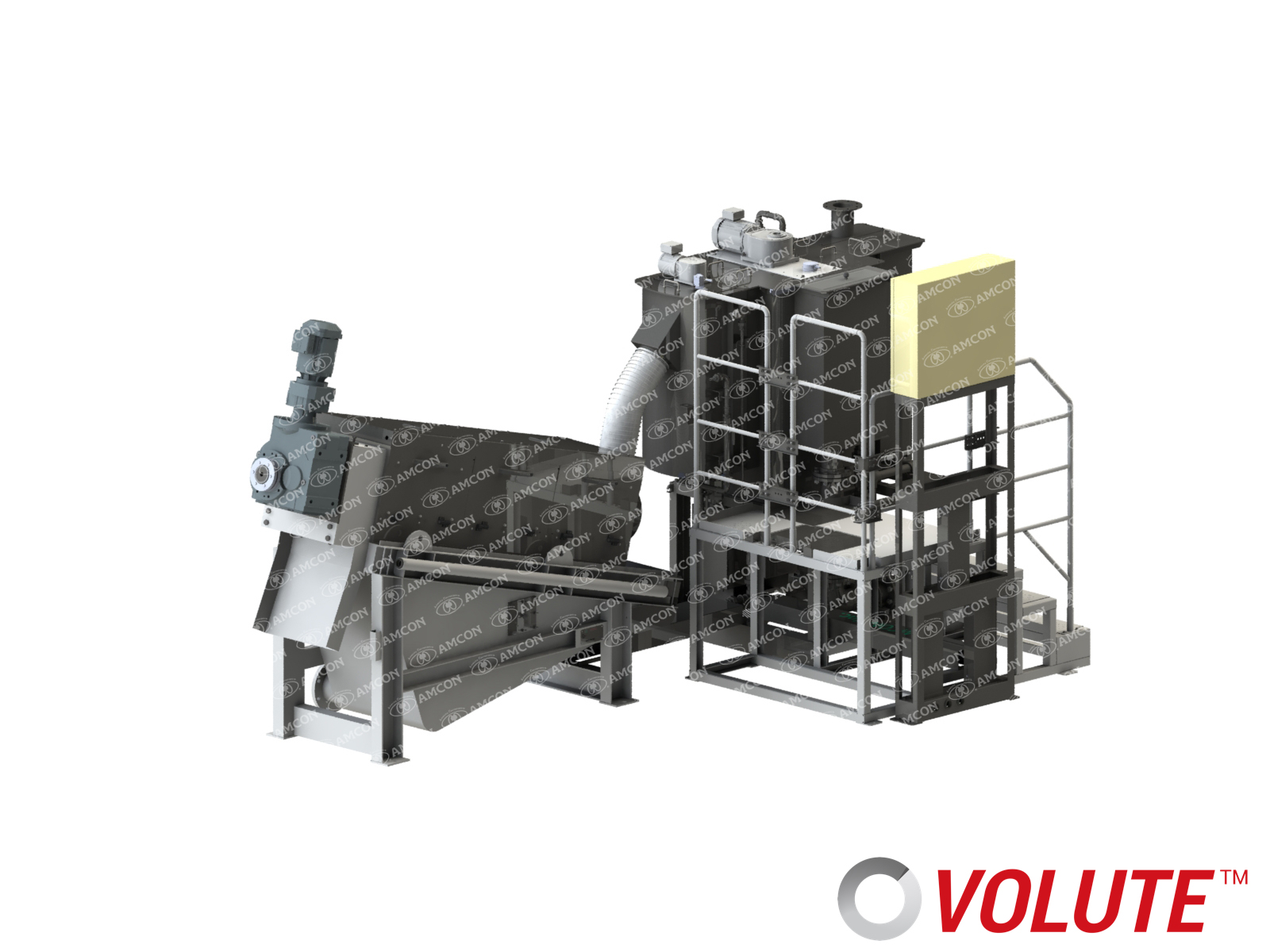

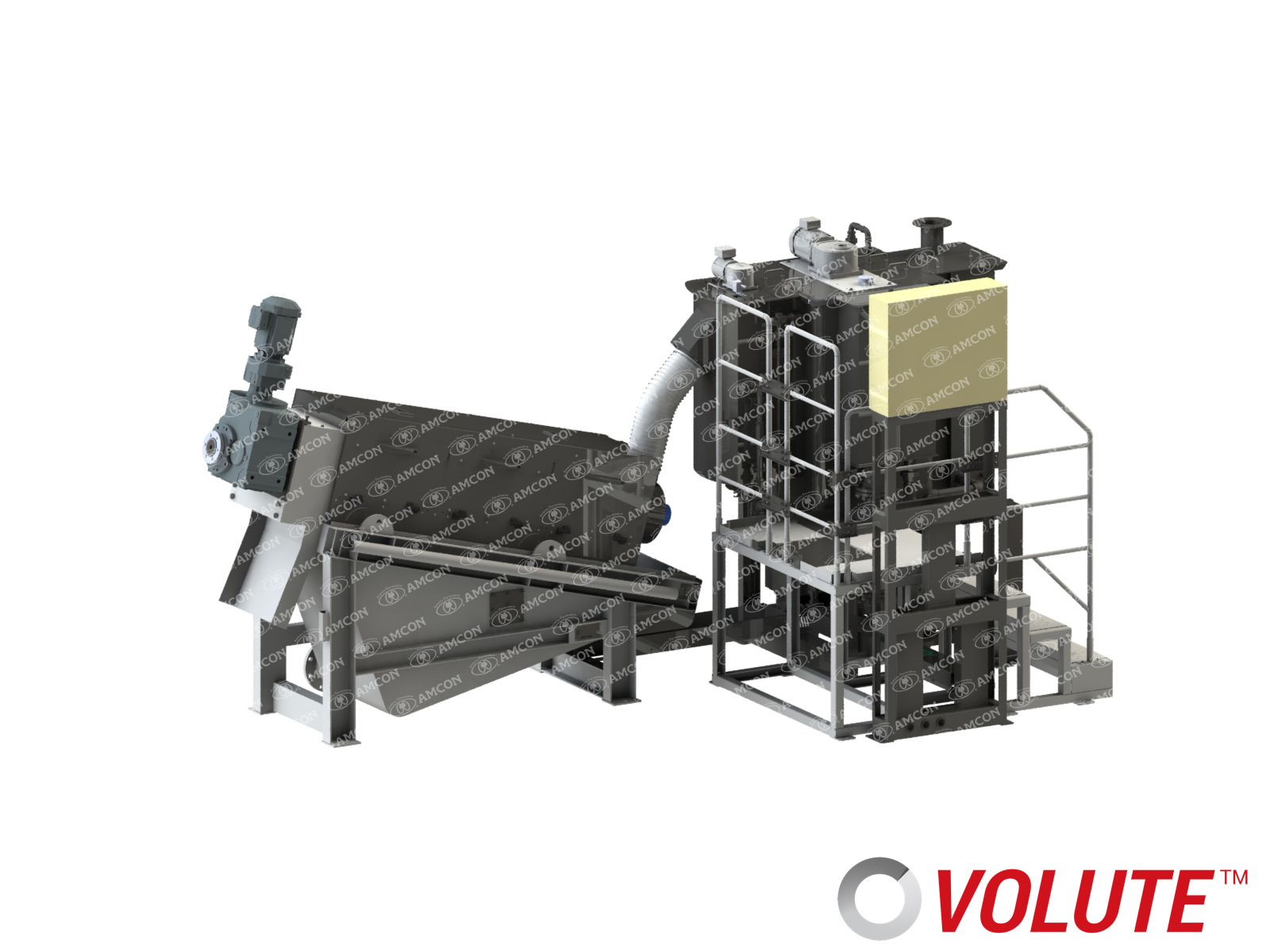

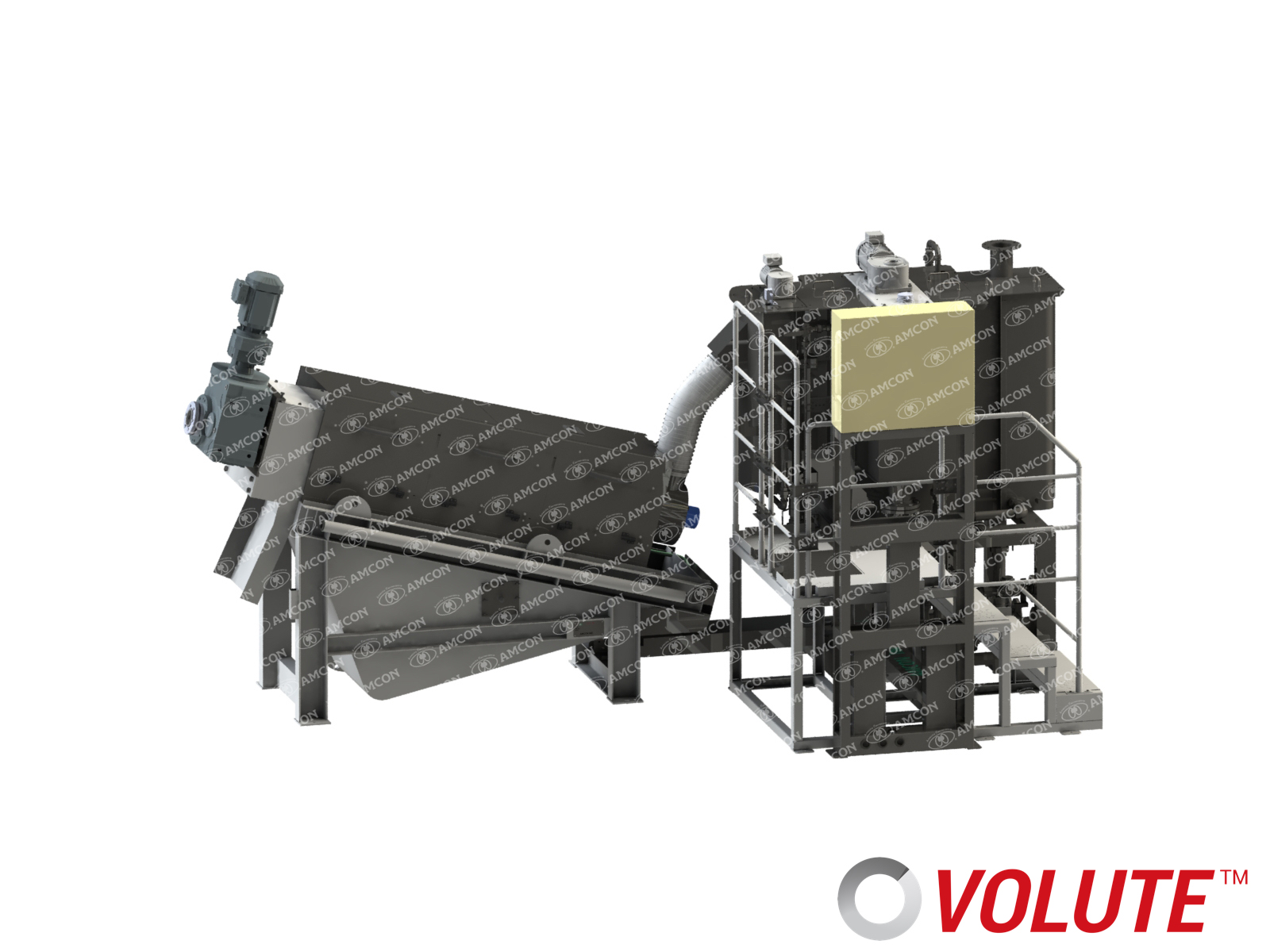

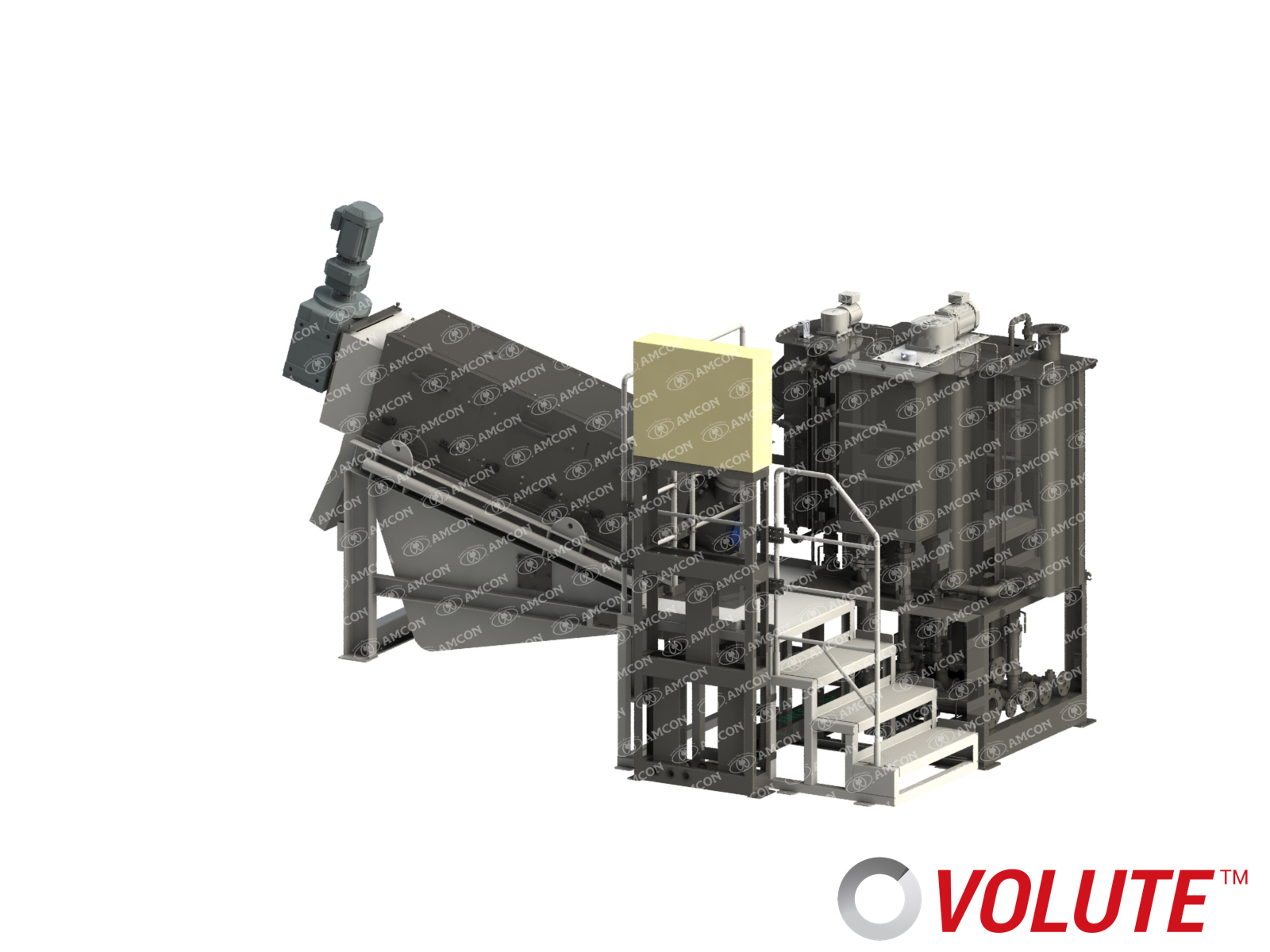

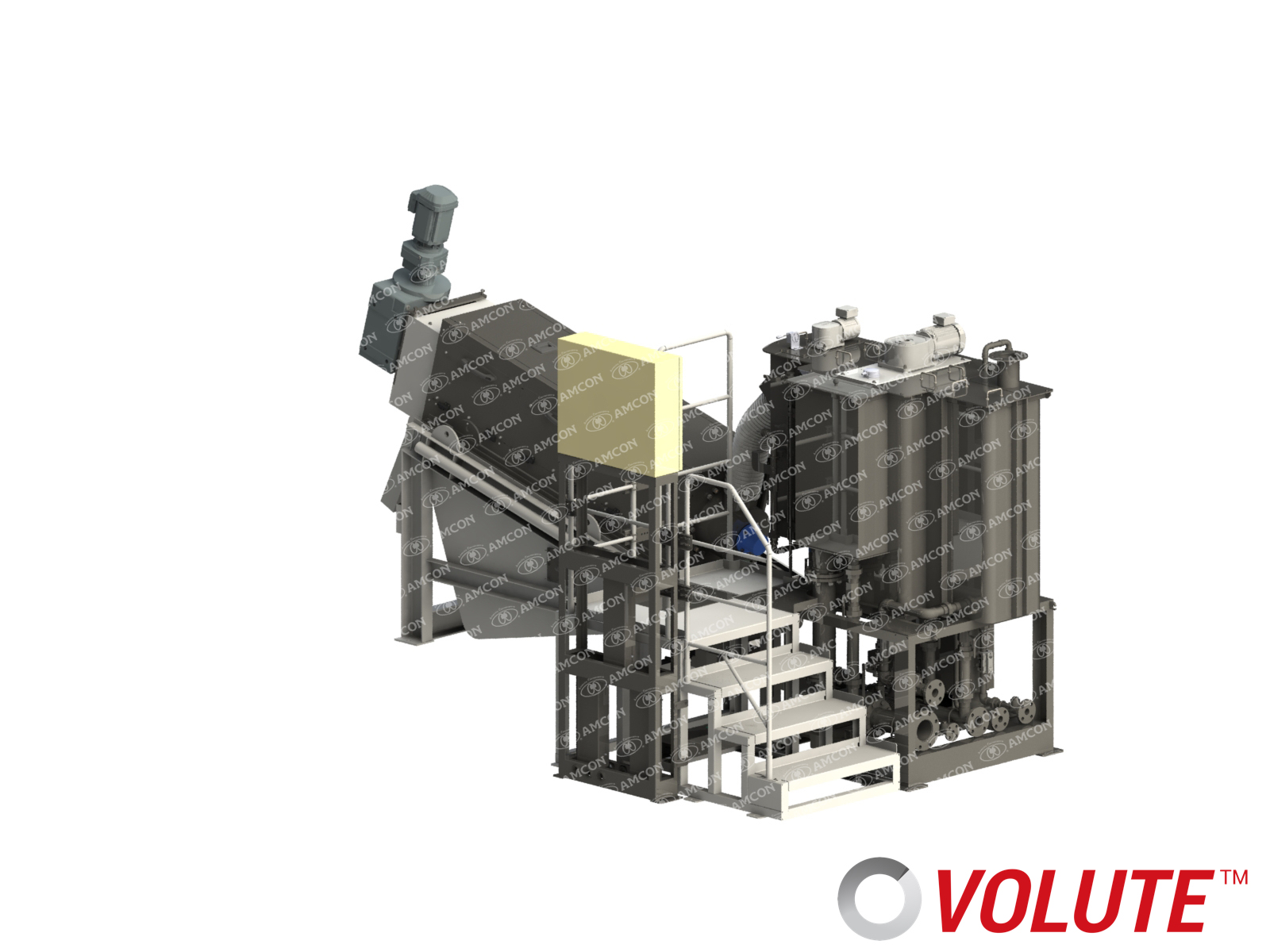

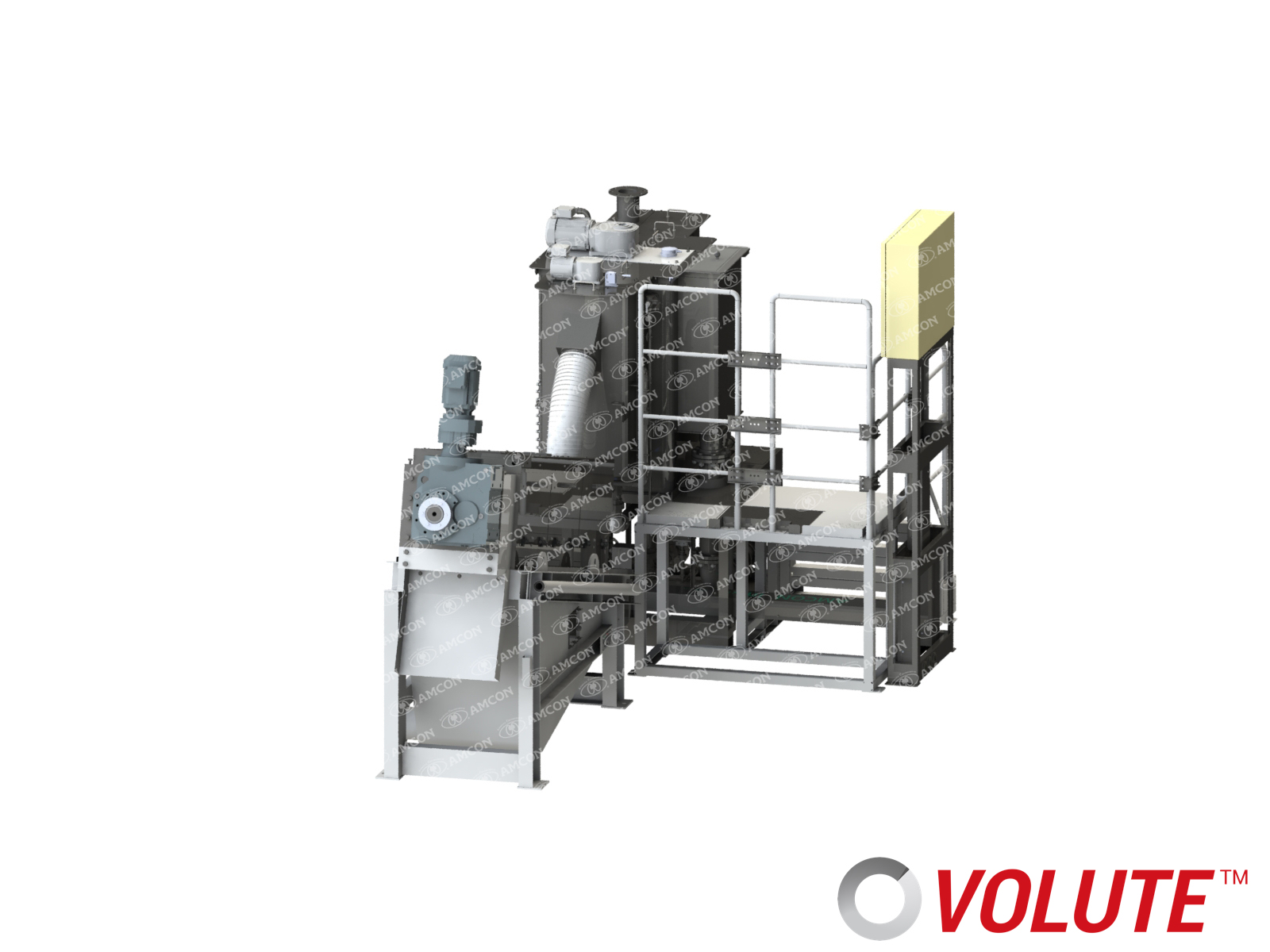

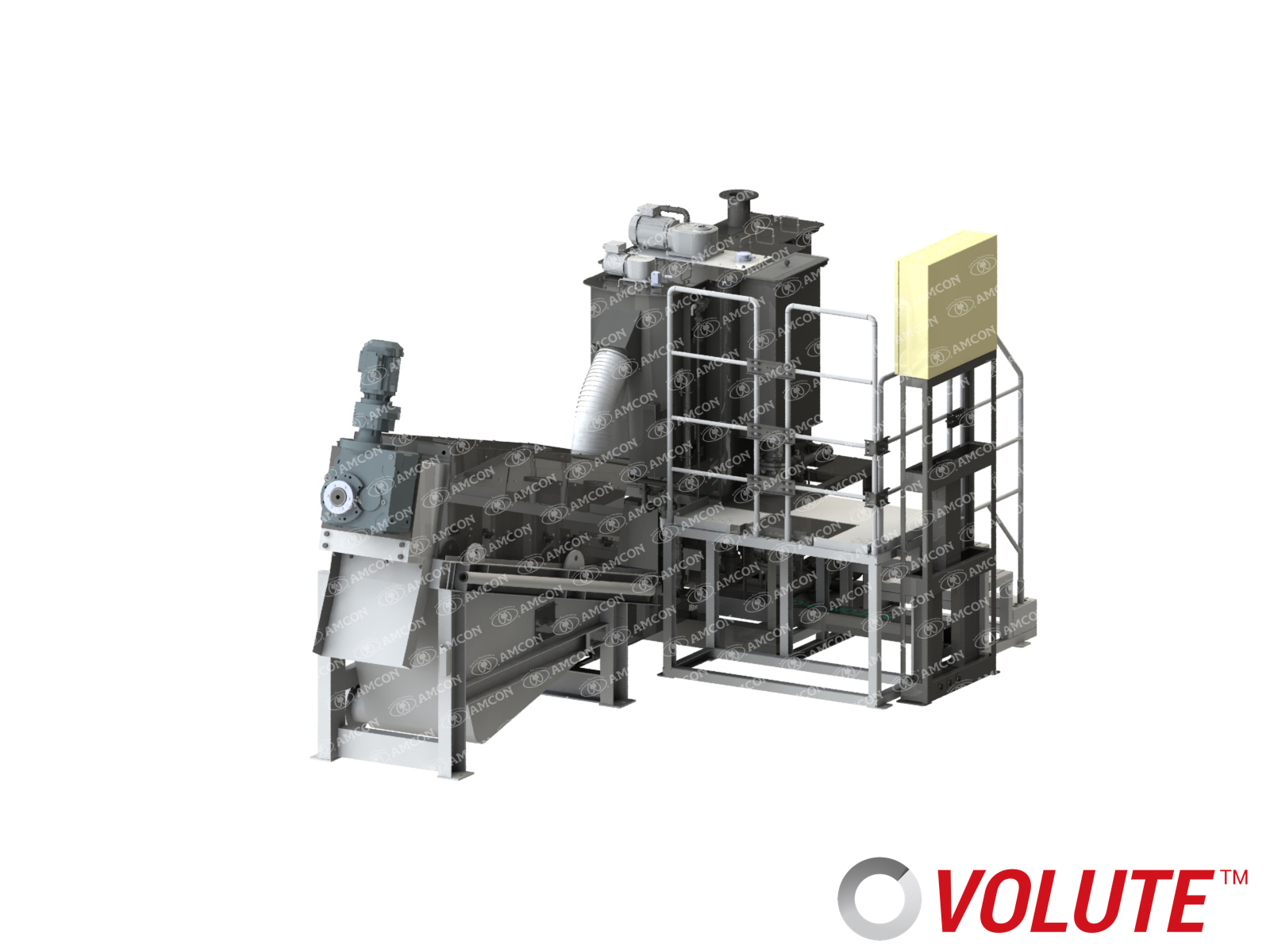

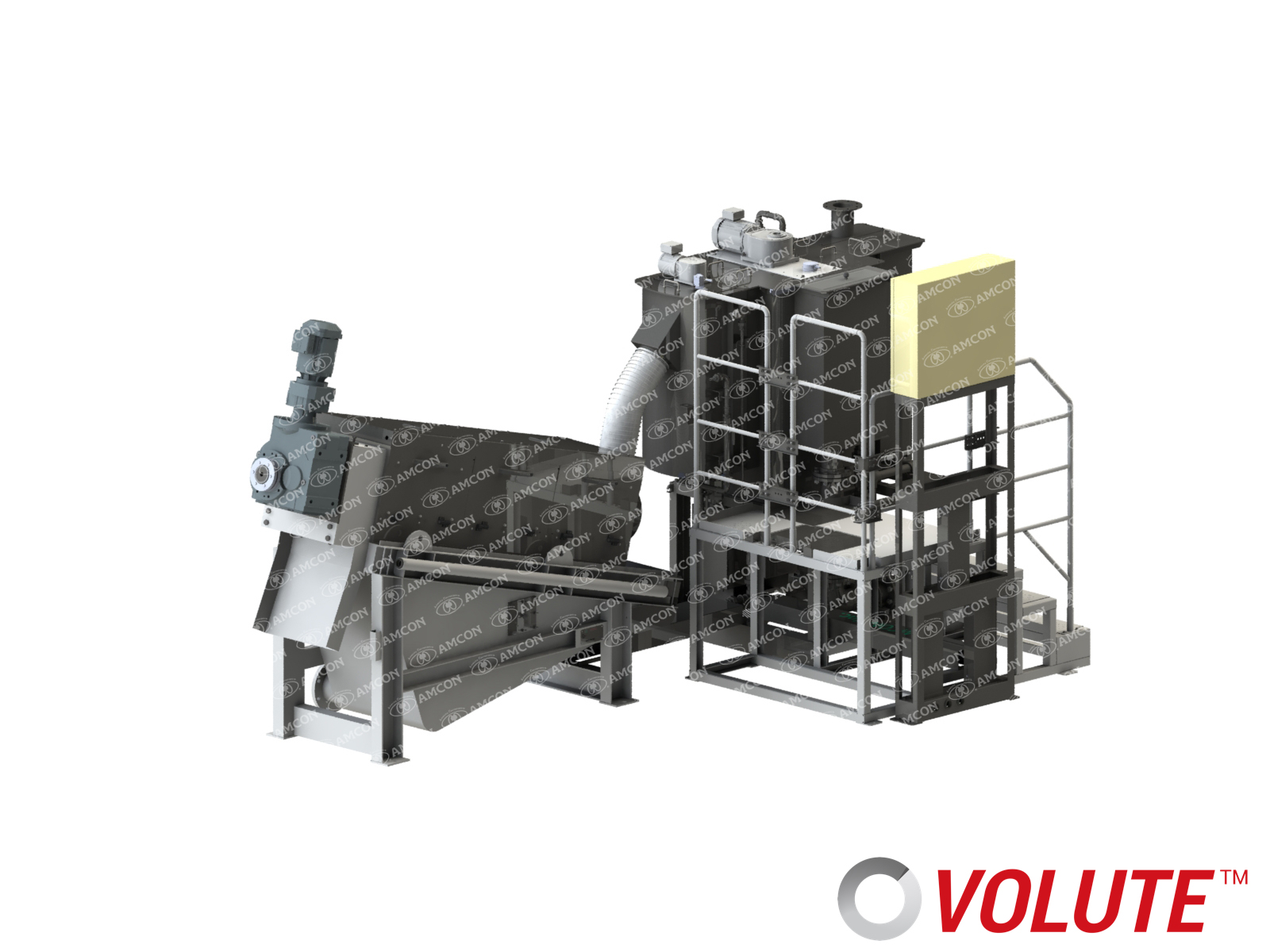

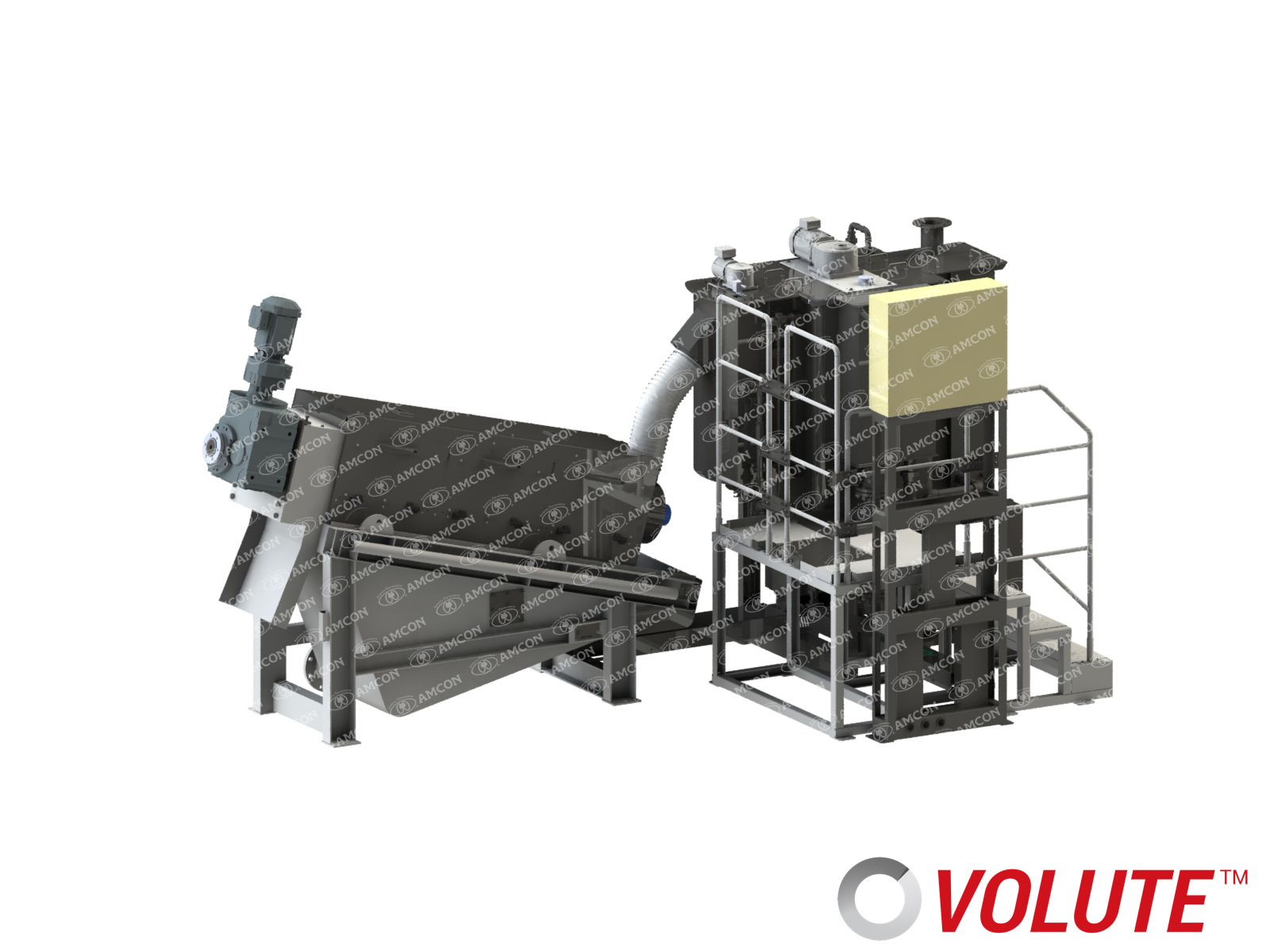

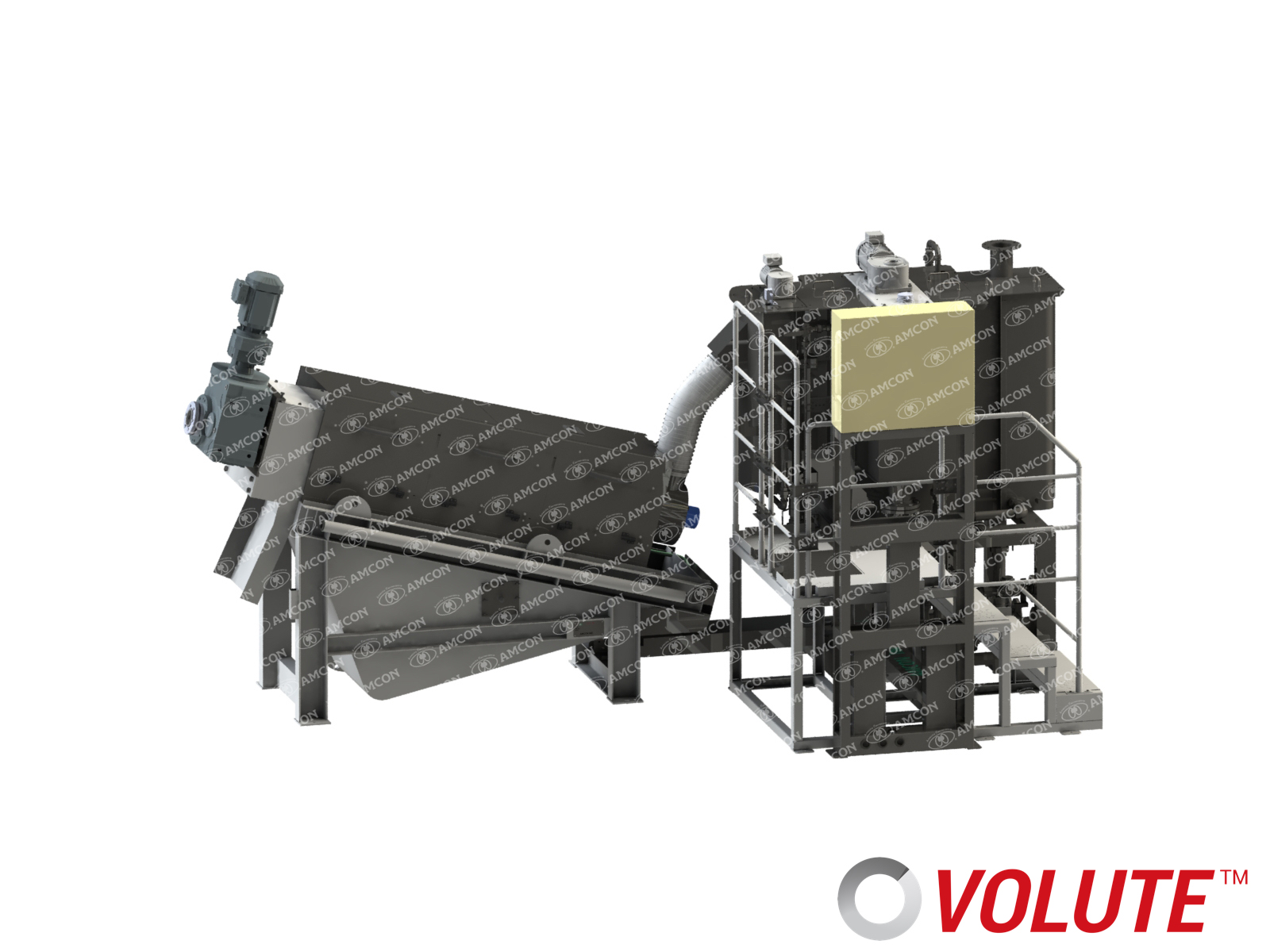

Excellent expandability

Excellent expandability

Additional cylinder unit can be added even after delivery

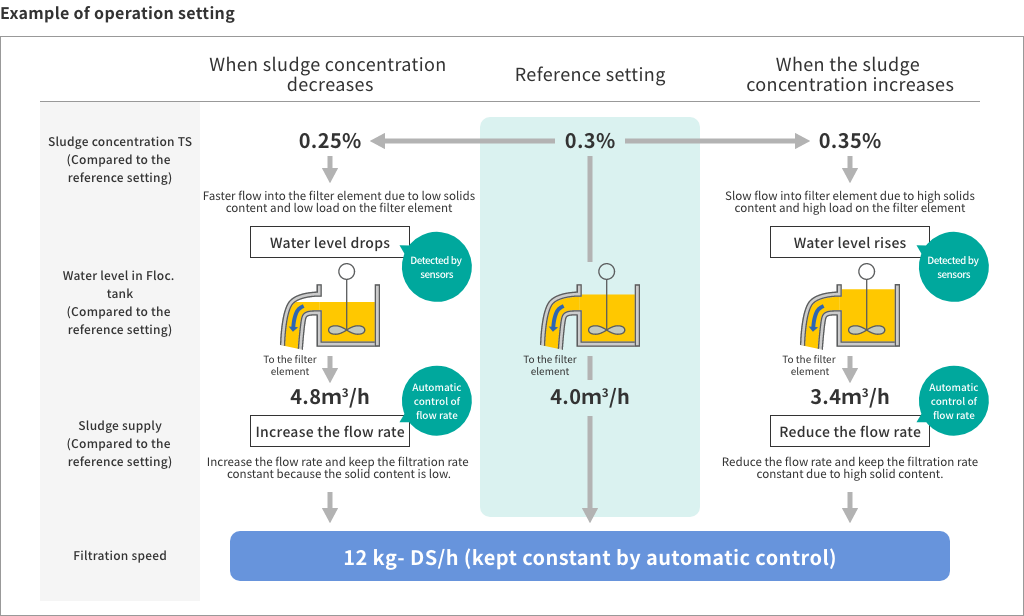

Realize stable operation with control responding to concentration fluctuation

In the treatment of mixed raw sludge, sludge properties such as sludge concentration and fibrous materials and those of seasonal sludge properties fluctuate greatly, which sometimes makes it difficult to adjust the operation of the sludge dewatering press, such as the amount of sludge fed and the amount of chemicals dosed.

In the MW series, a level sensor detects water level fluctuations in the flocculation tank, and even when the concentration of the sludge fed into the sludge dewatering press fluctuates (TS of 2.5 to 3.8%), the system automatically adjusts the amount of sludge fed into the filter to maintain that an amount of solids fed into the filter element is constant. This allows the operation with constant water content and filtration speed without changing the operation settings each time the concentration changes.

Life cycle costs can be reduced

Life cycle costs can be reduced at any sewage treatment plant, regardless of the scale of sewage treatment.

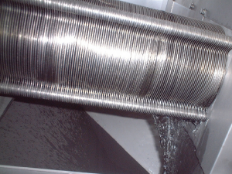

Overhaul and replacement of consumable parts performed on-site in a short time

To maintain the dewatering performance and extend the service life of the sludge dewatering press, the consumable parts that make up the filtration zone need to be replaced periodically according to operating hours. Since the filtration zone has an independent structure, they can be easily replaced on-site without taking the machine back to our factory for replacement of consumable parts.

Parts replacement can be done in a short time; thus you can reduce the time required to shut down the sludge dewatering press.

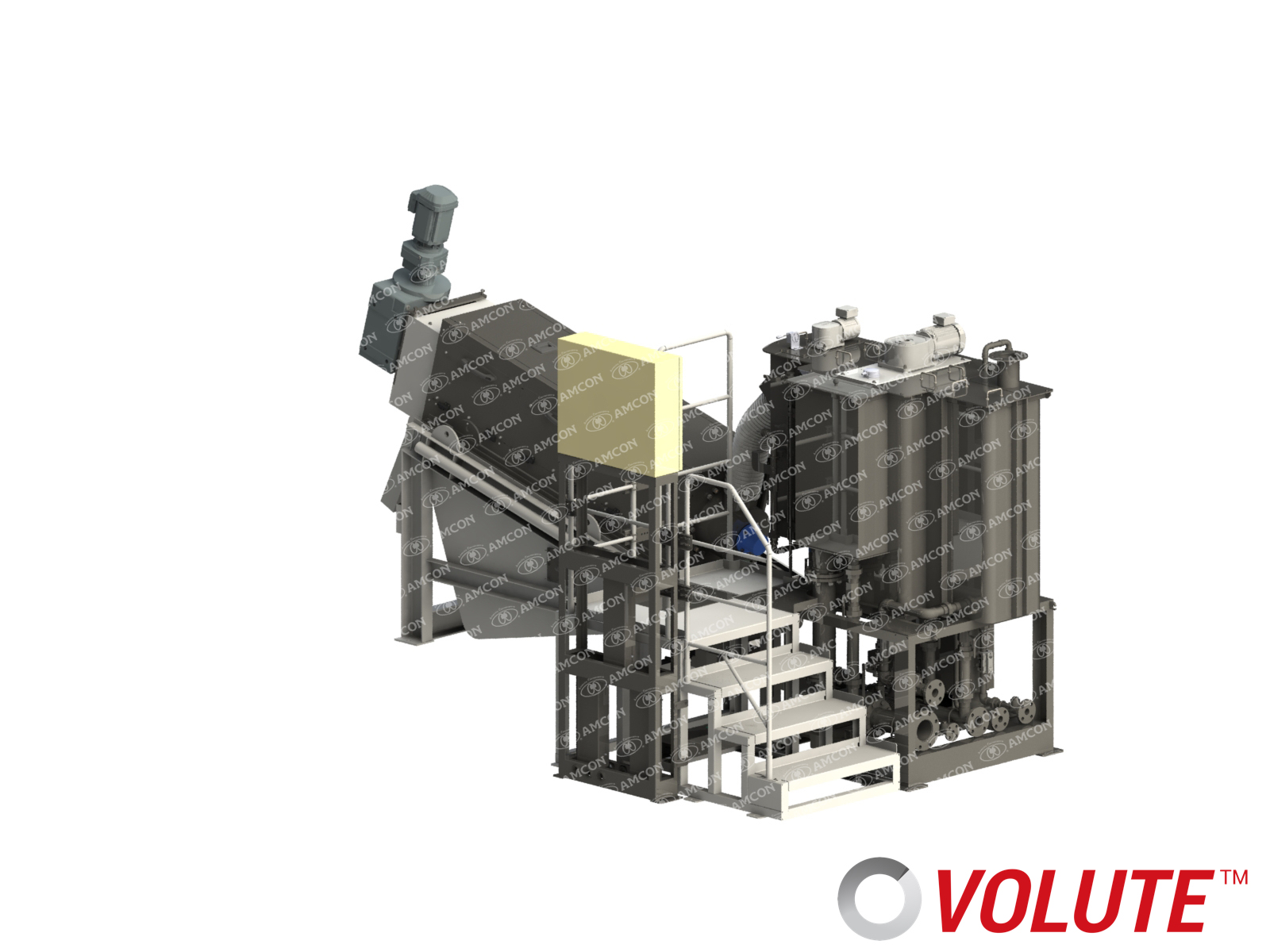

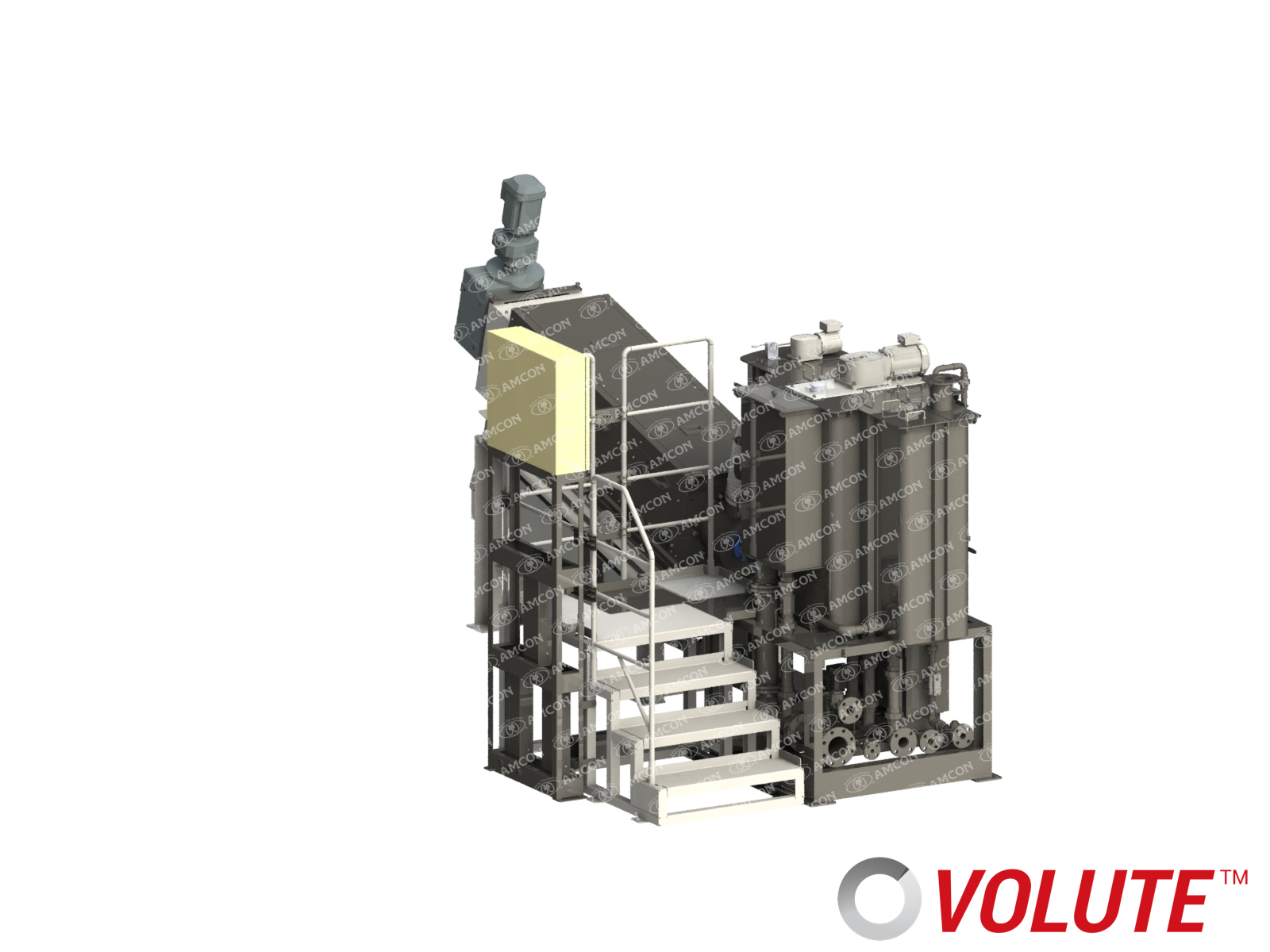

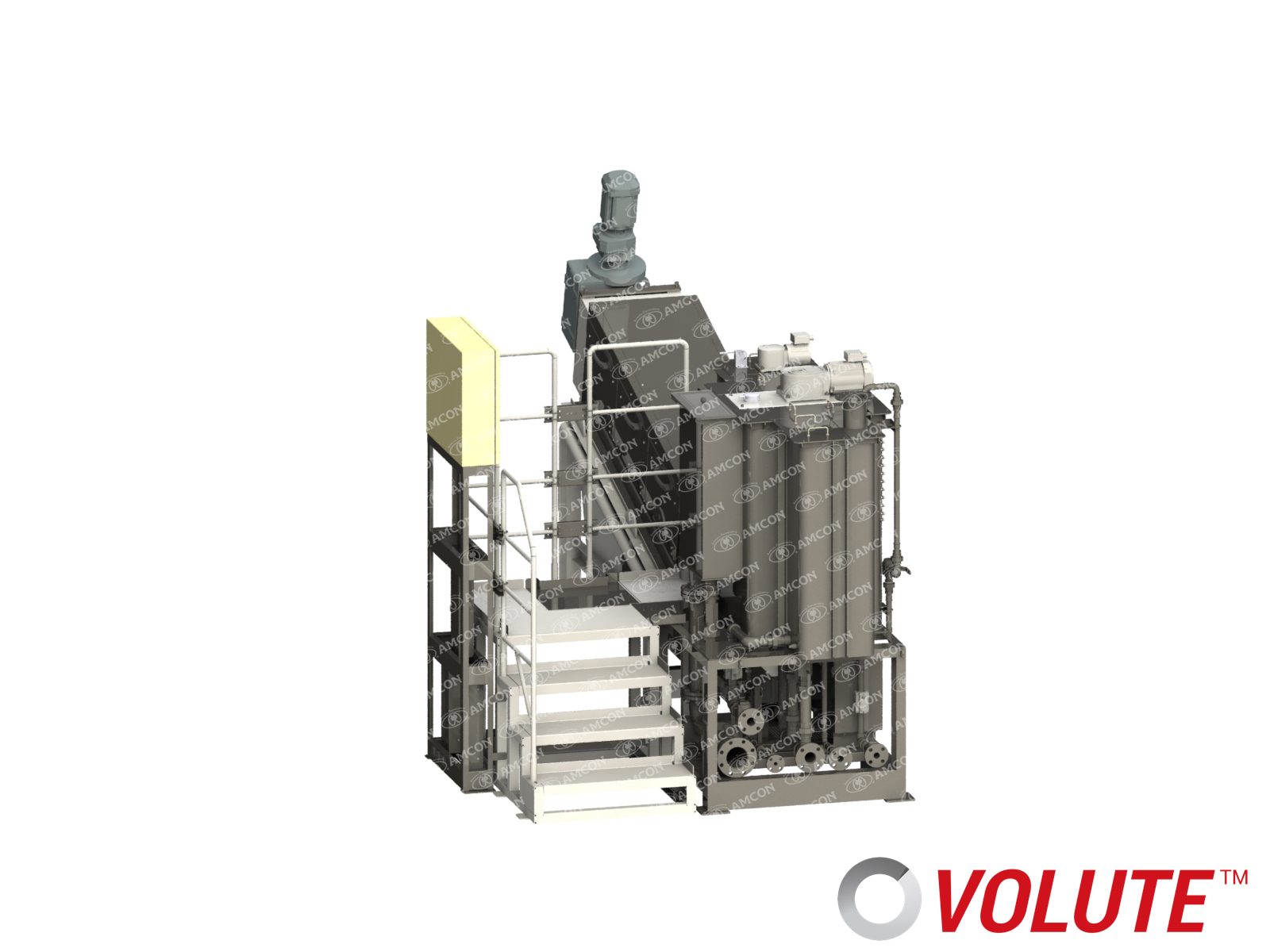

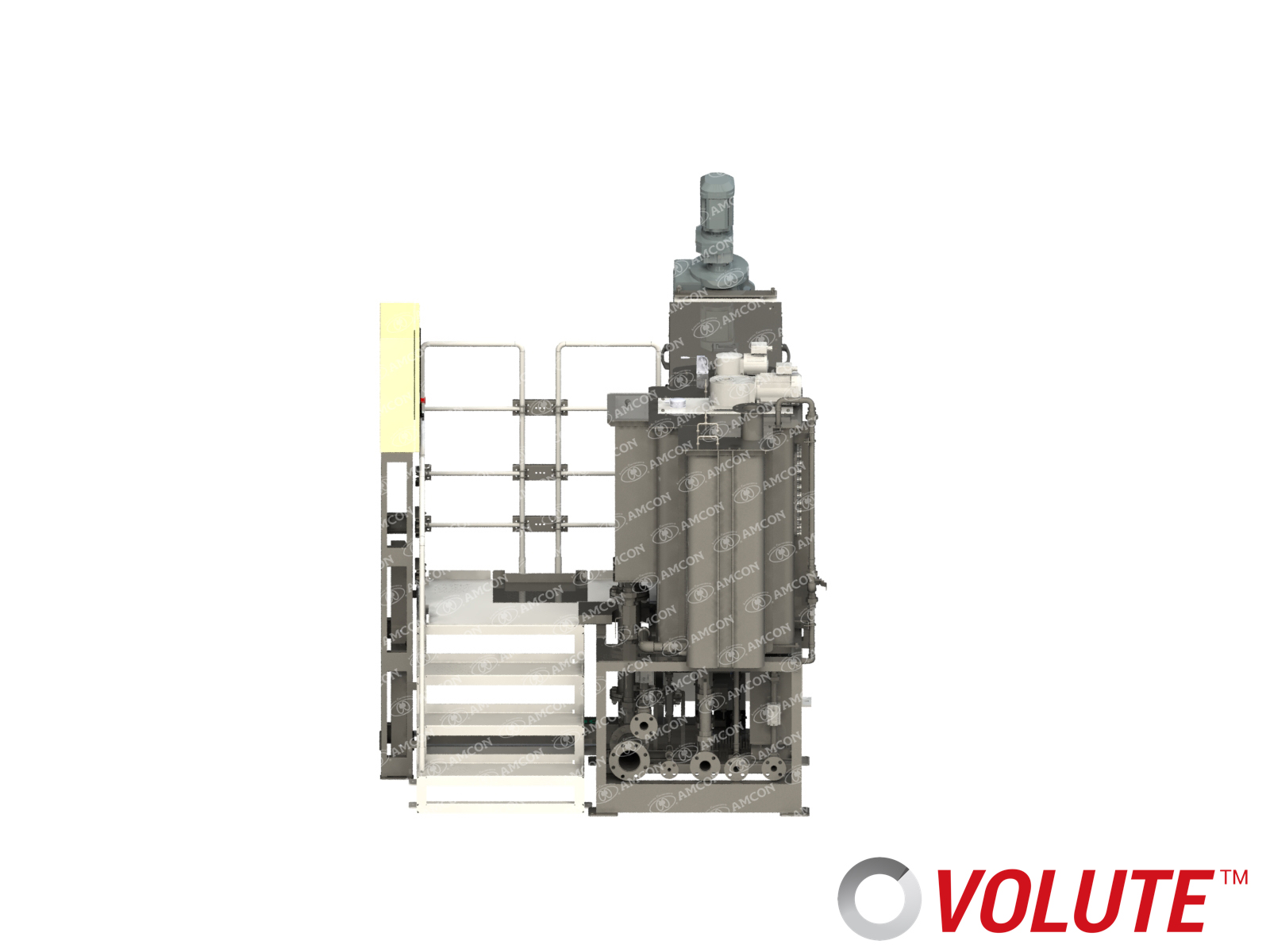

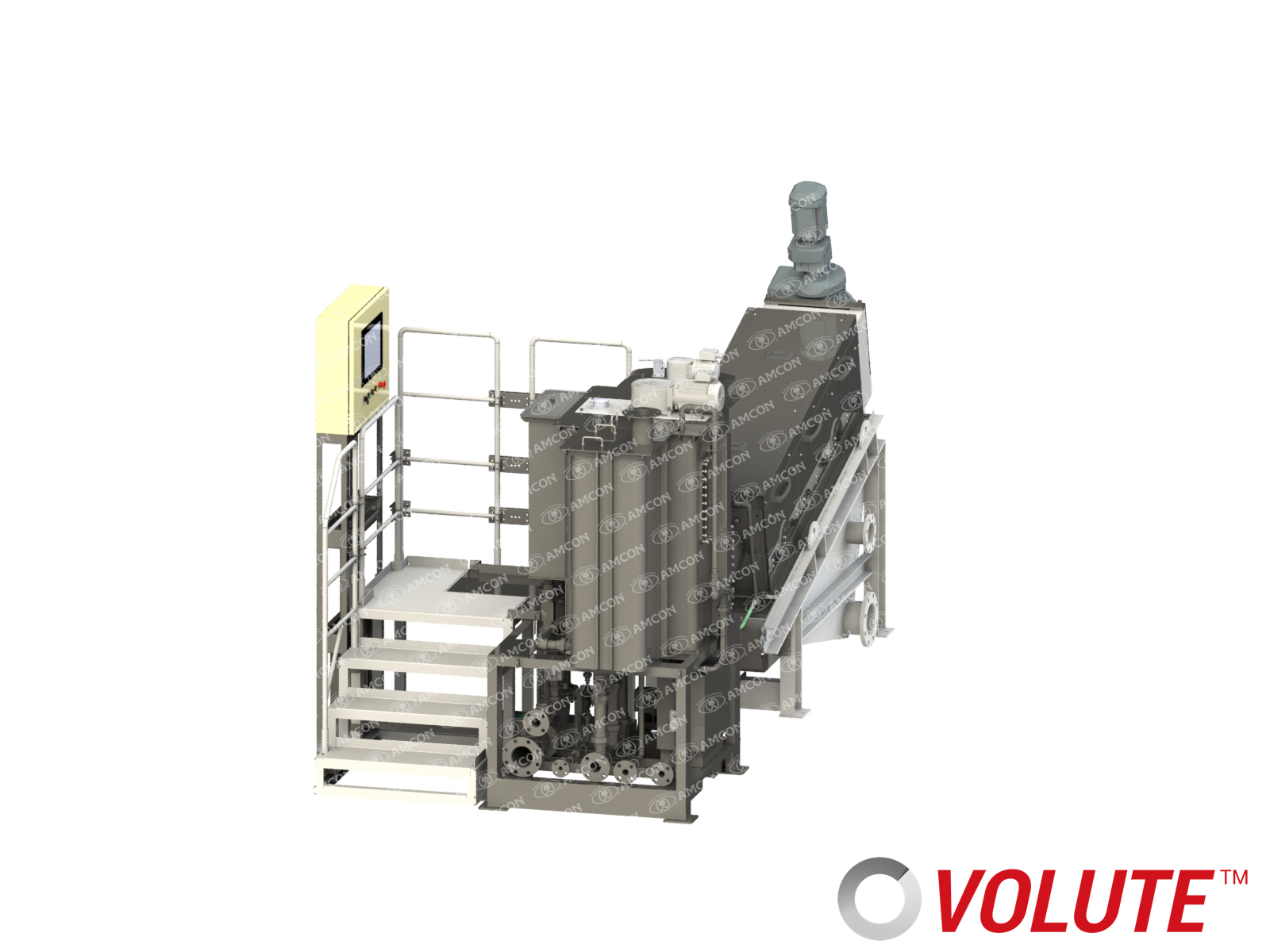

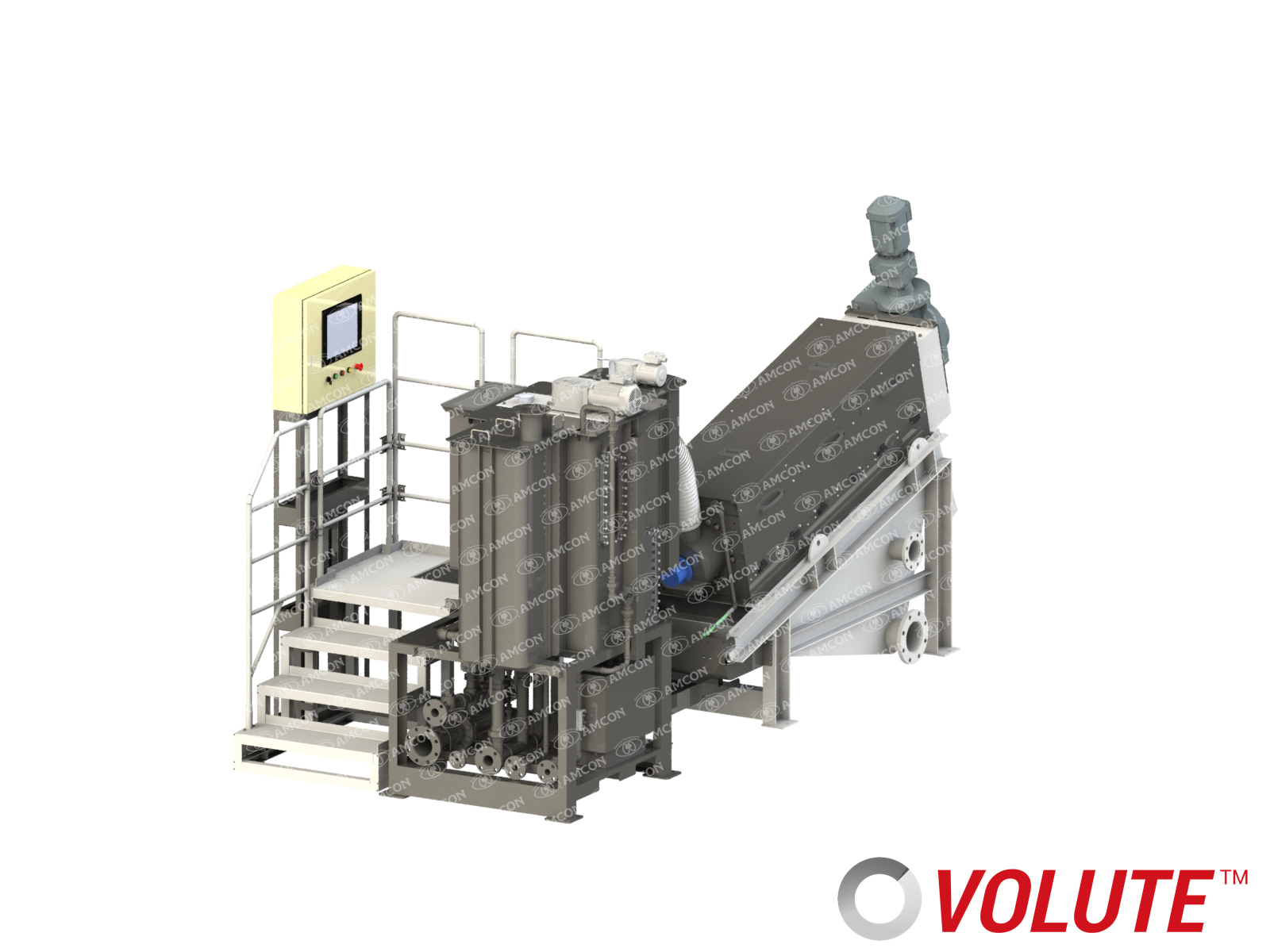

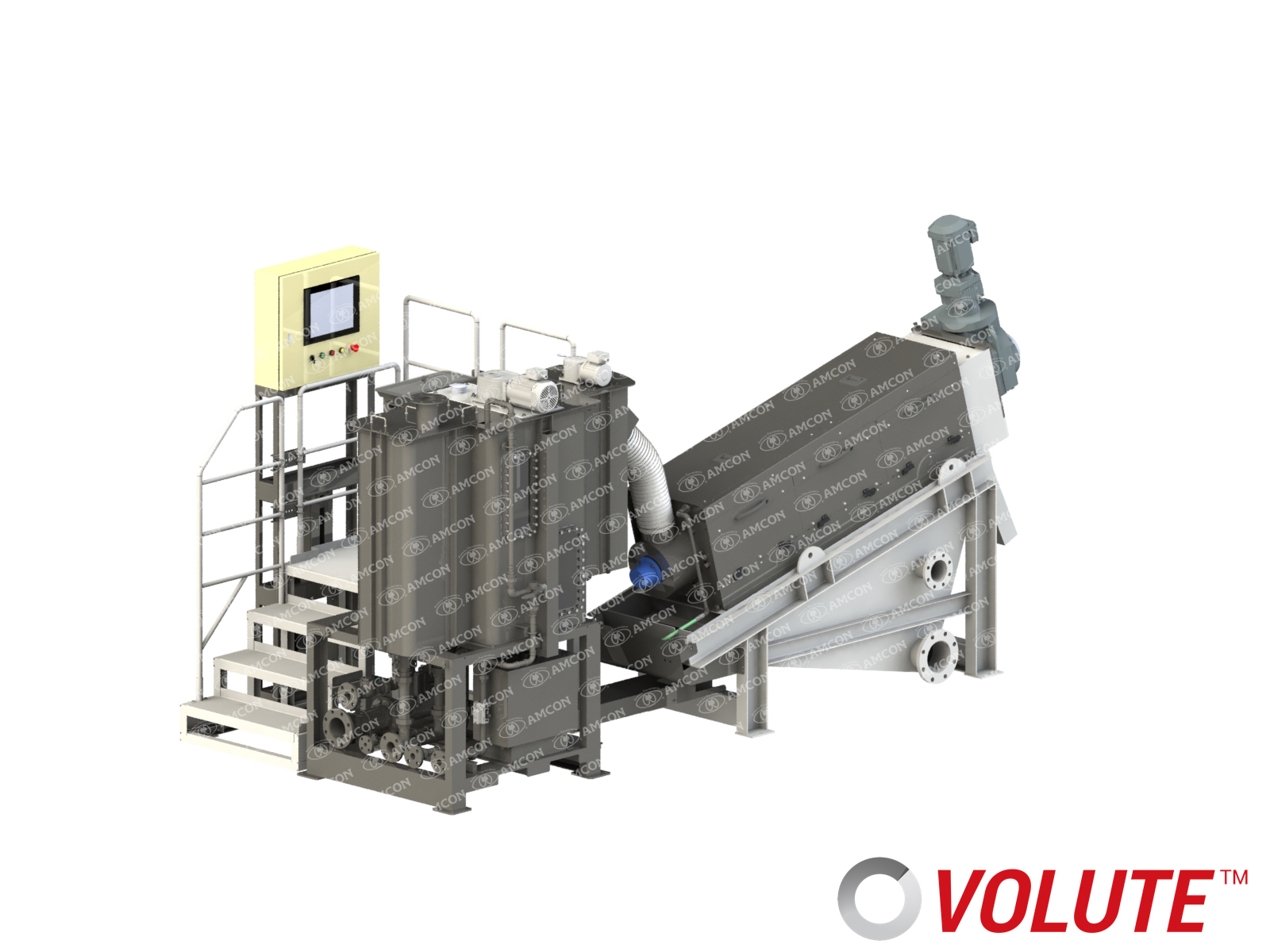

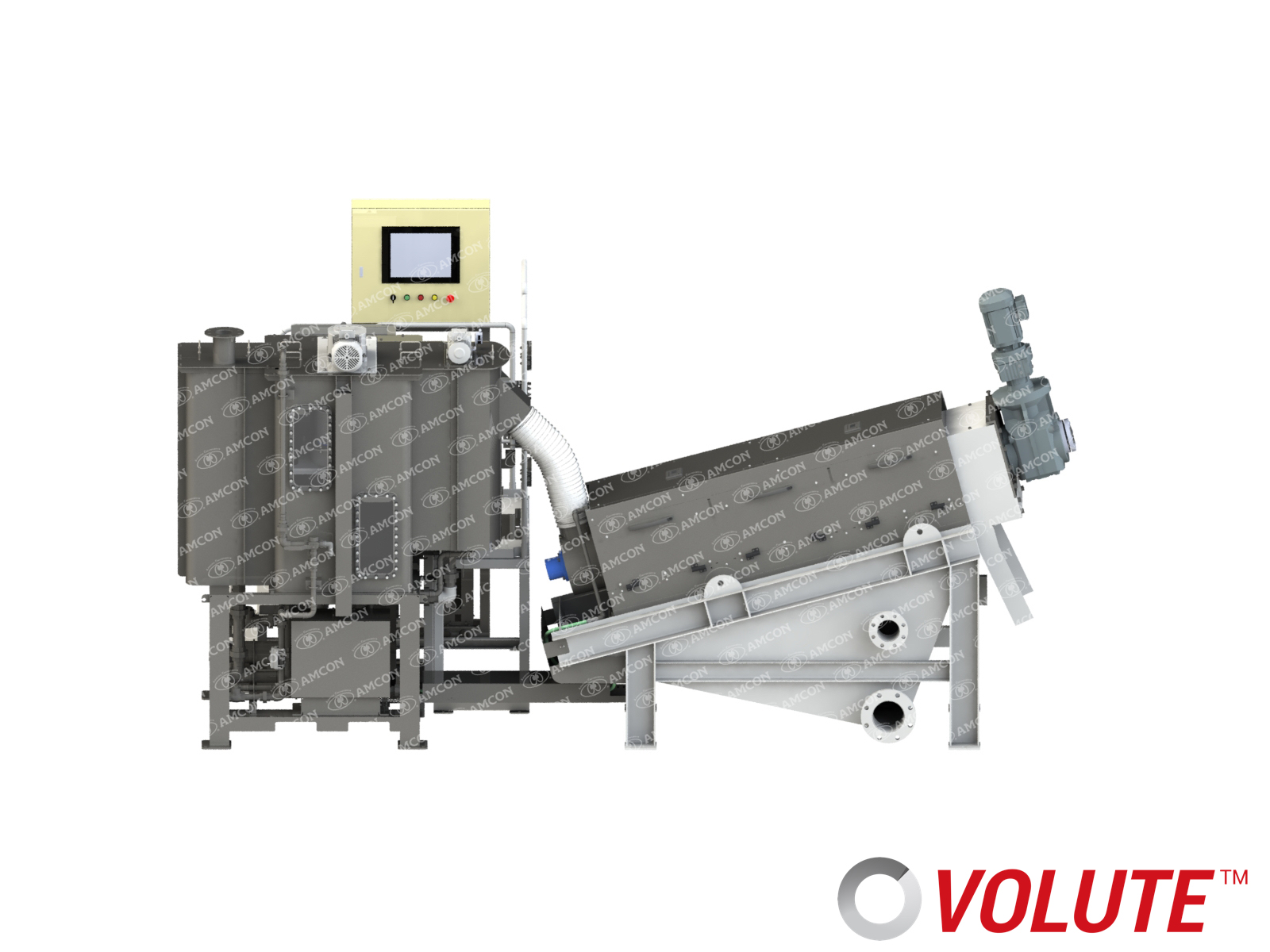

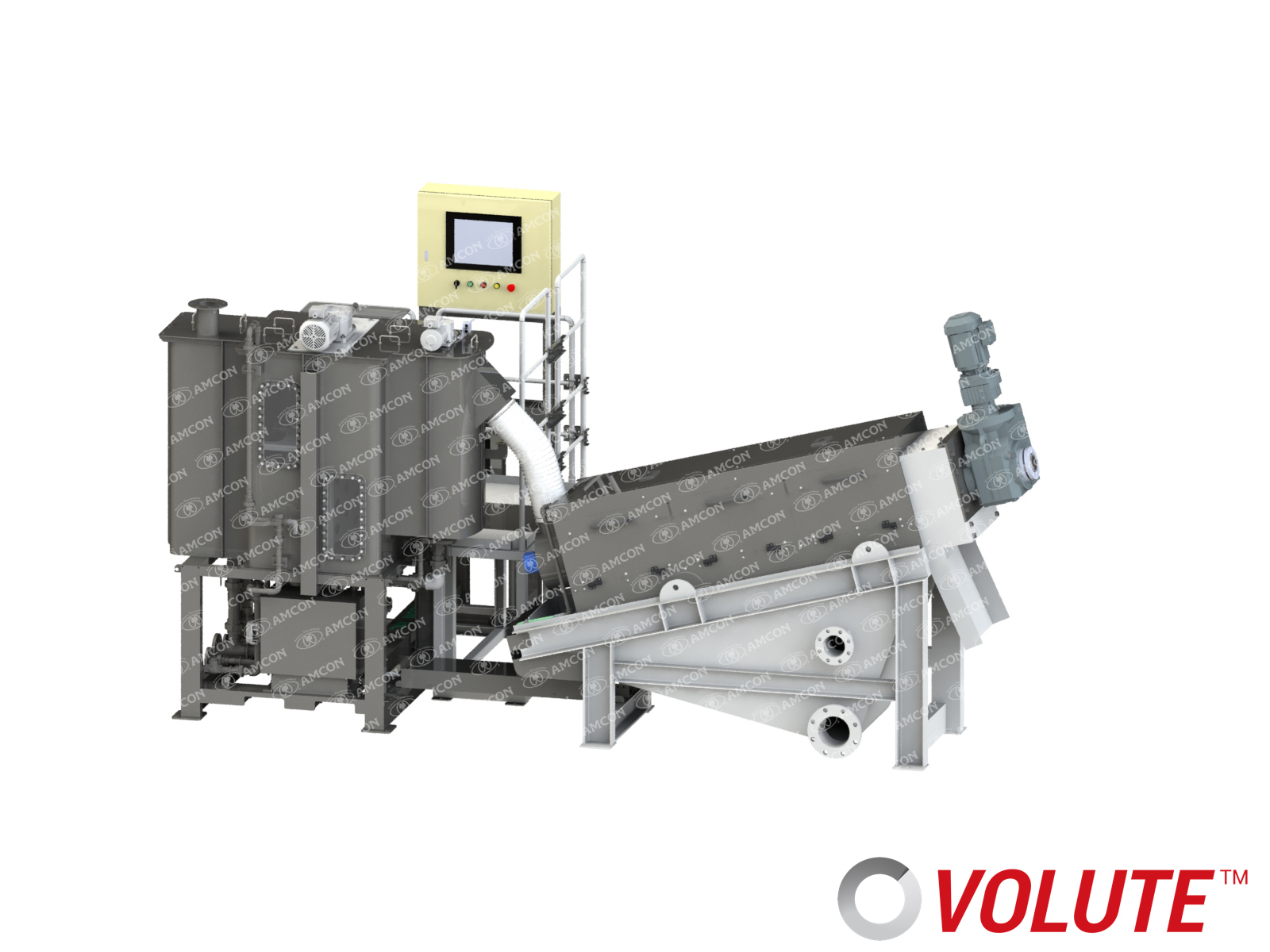

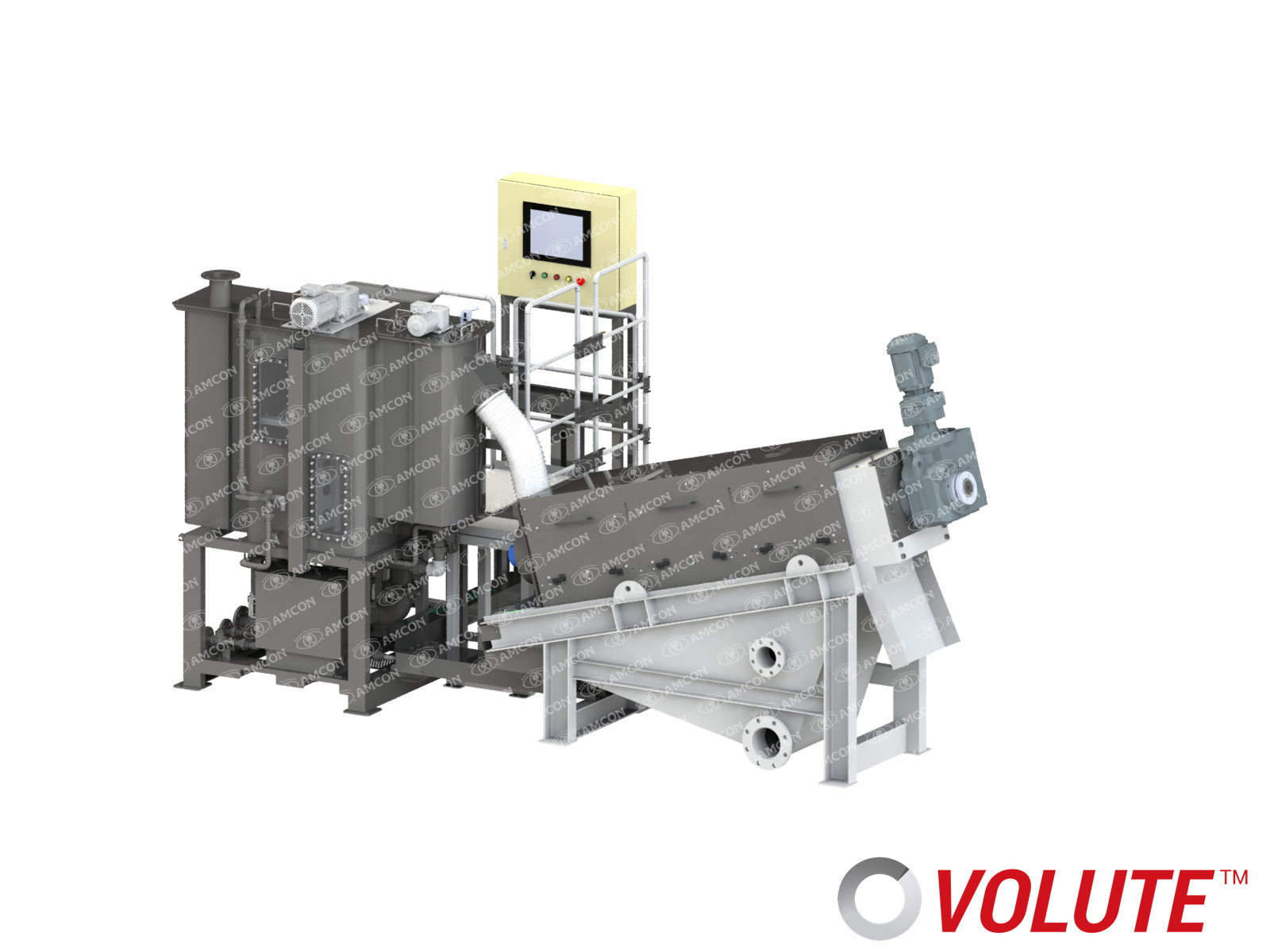

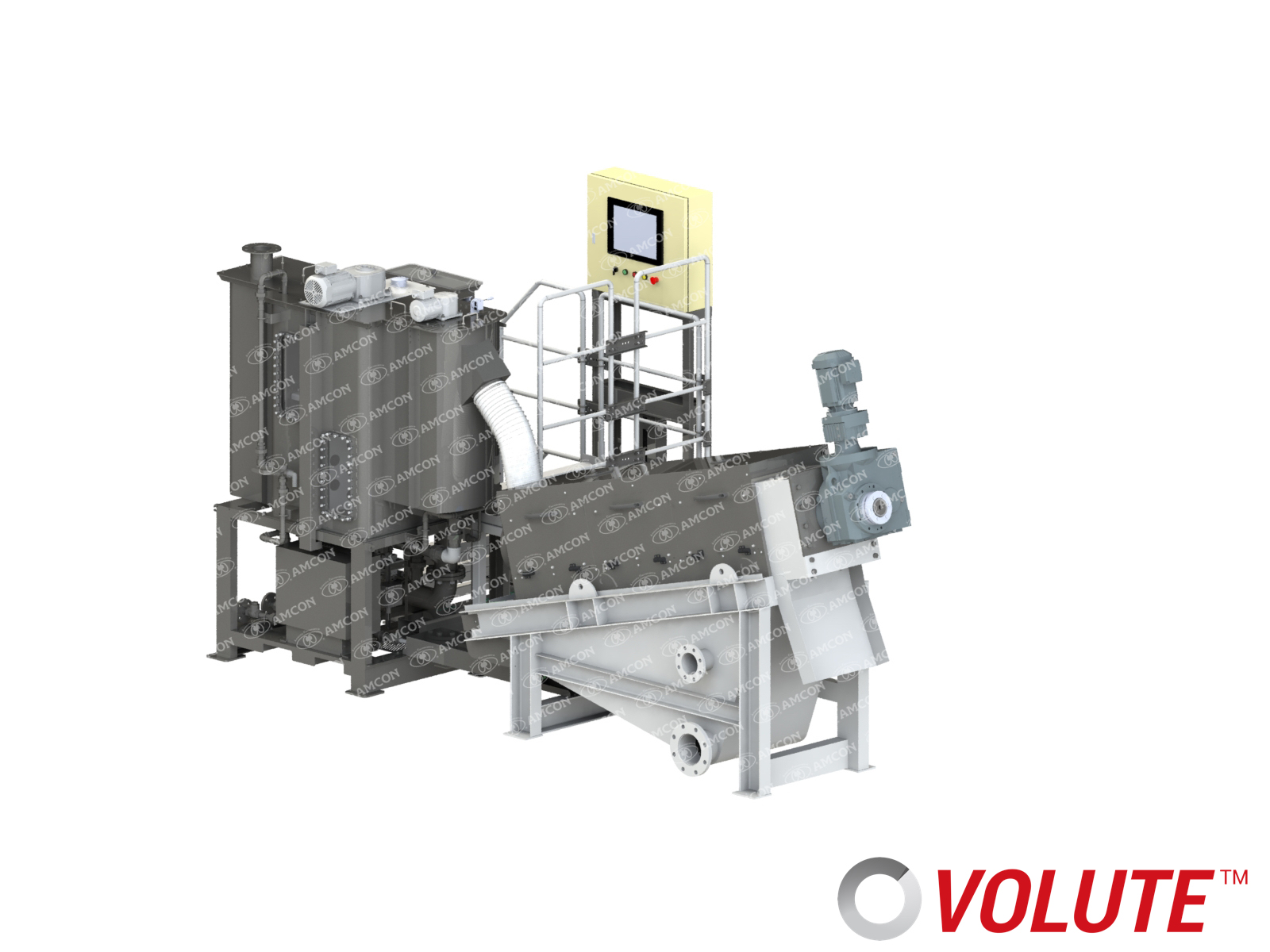

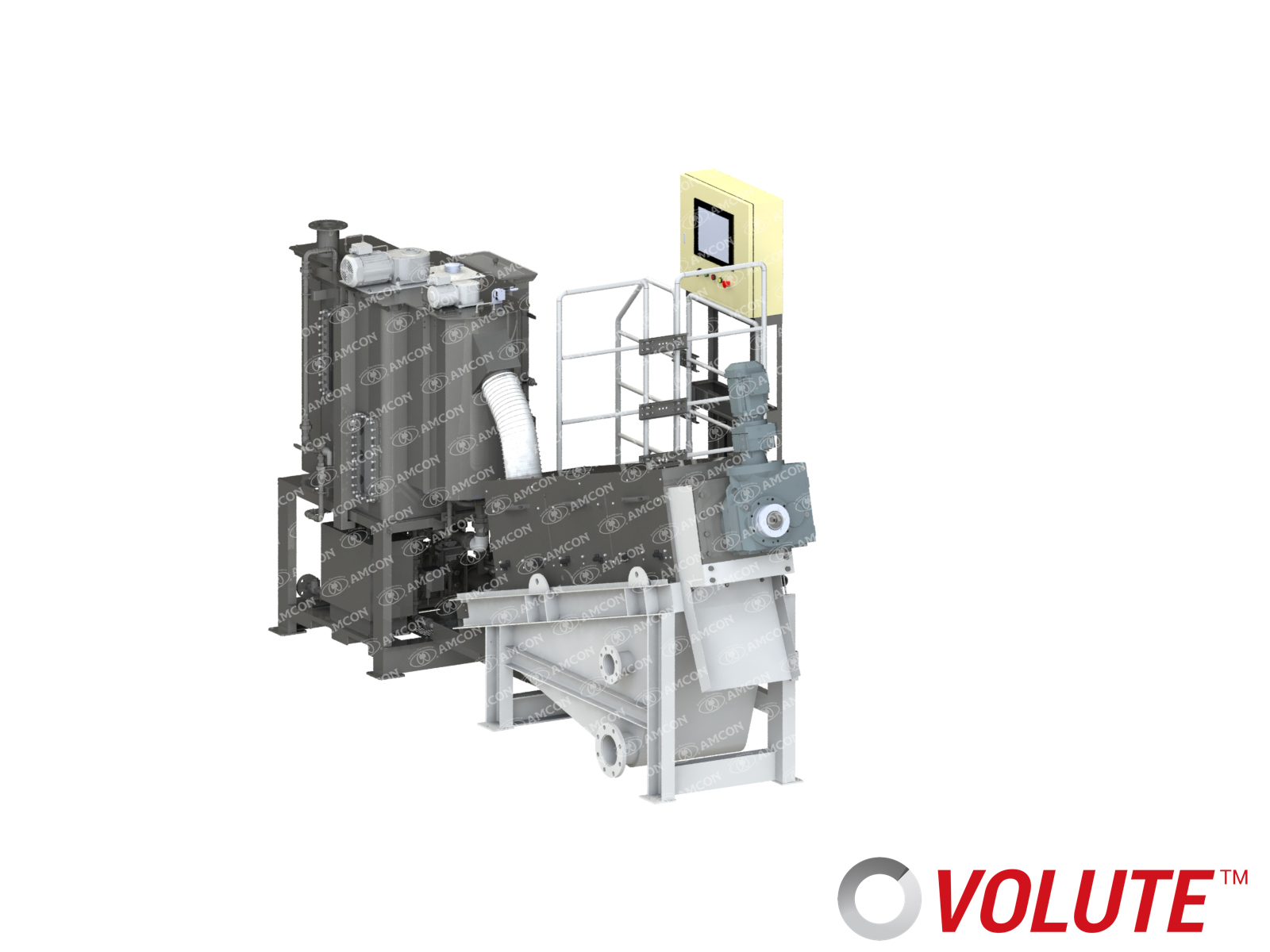

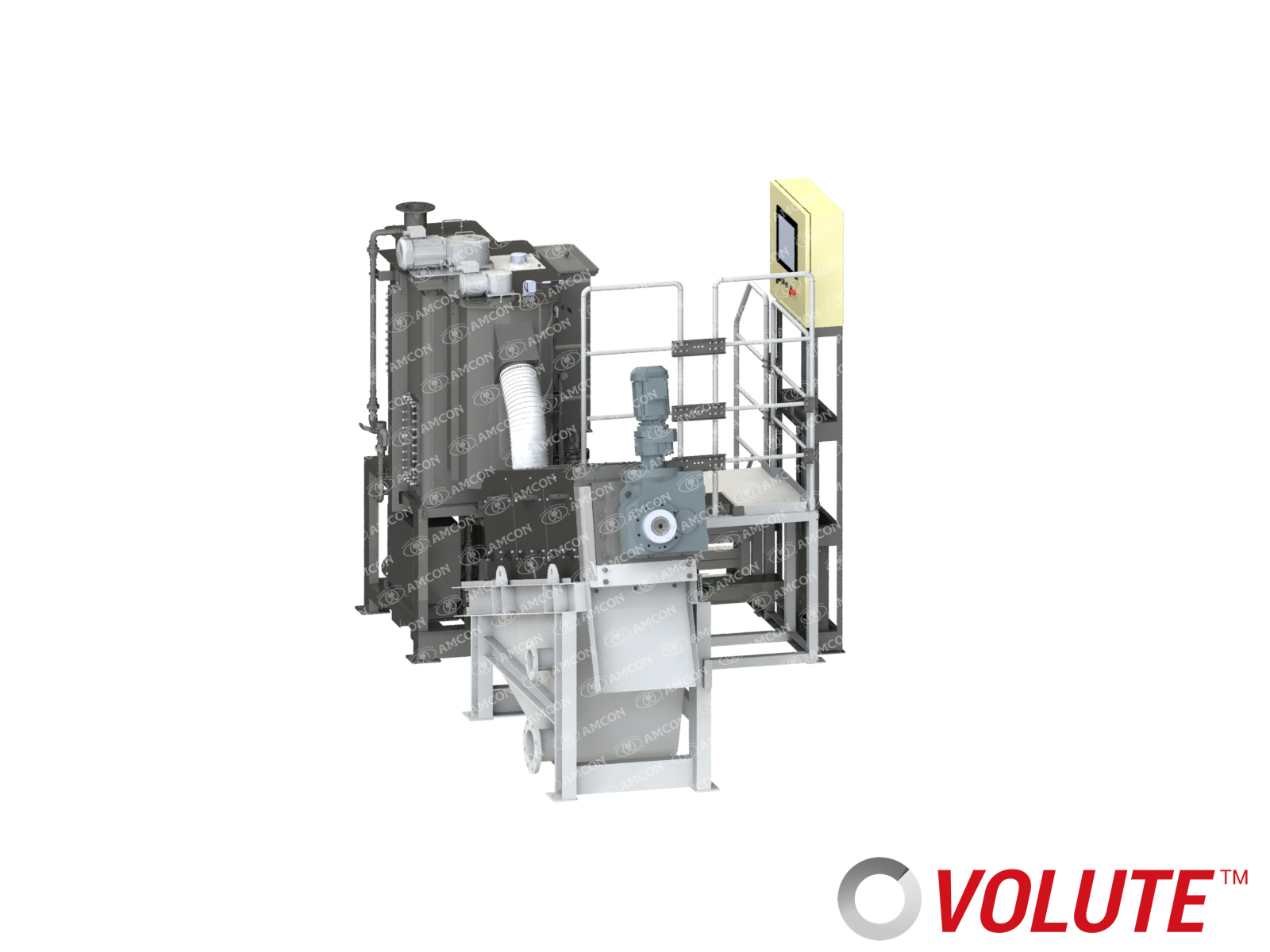

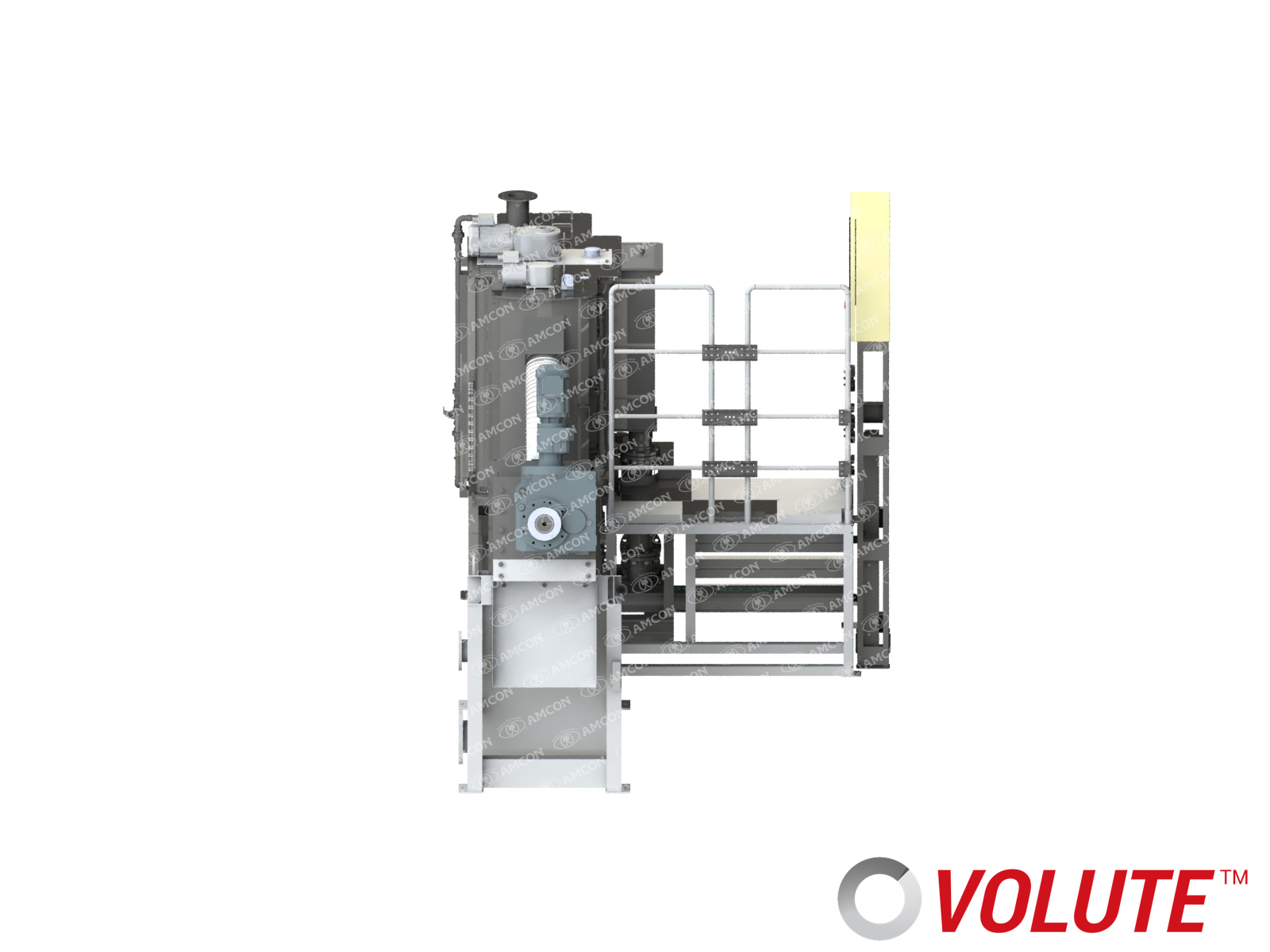

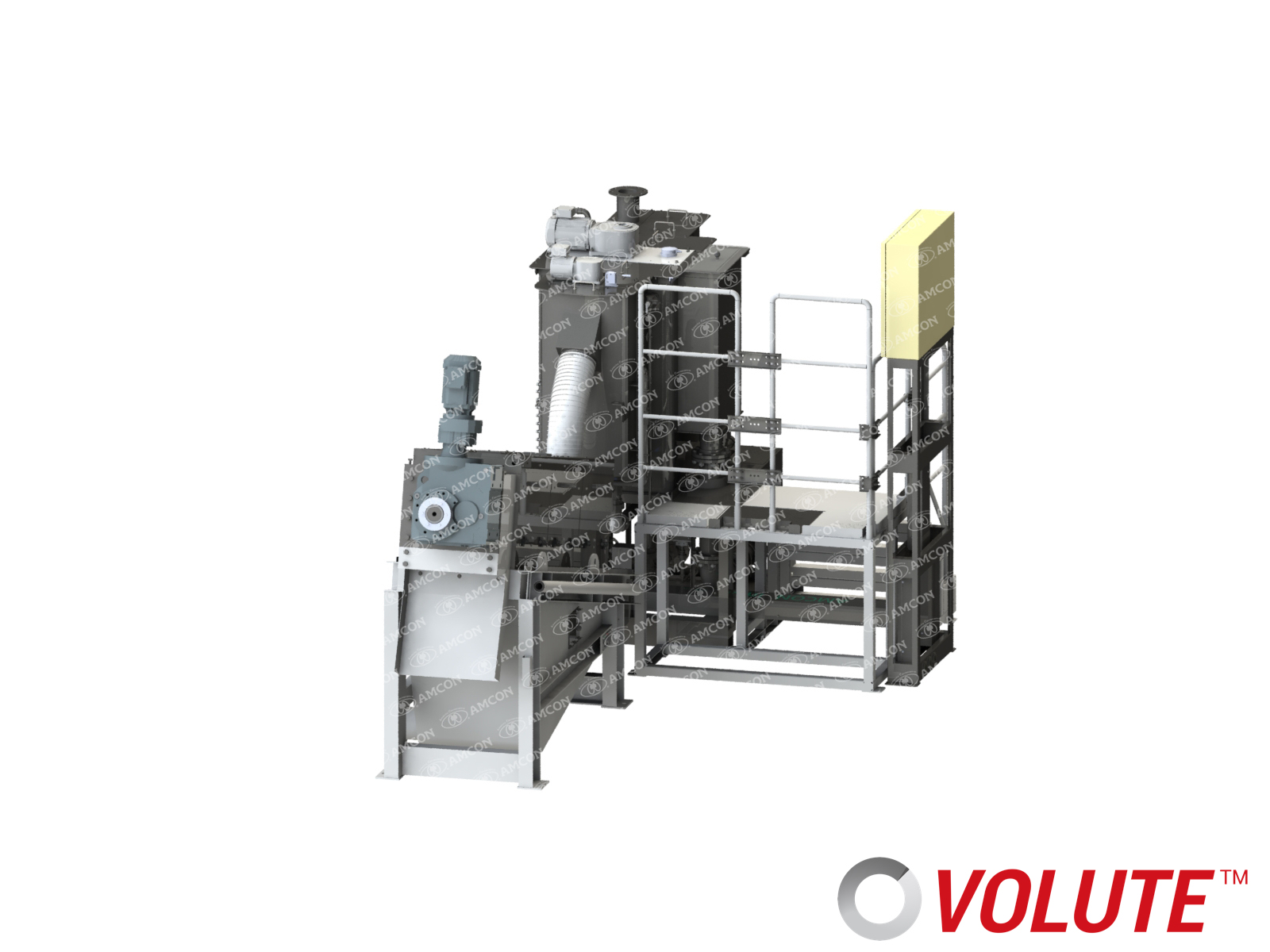

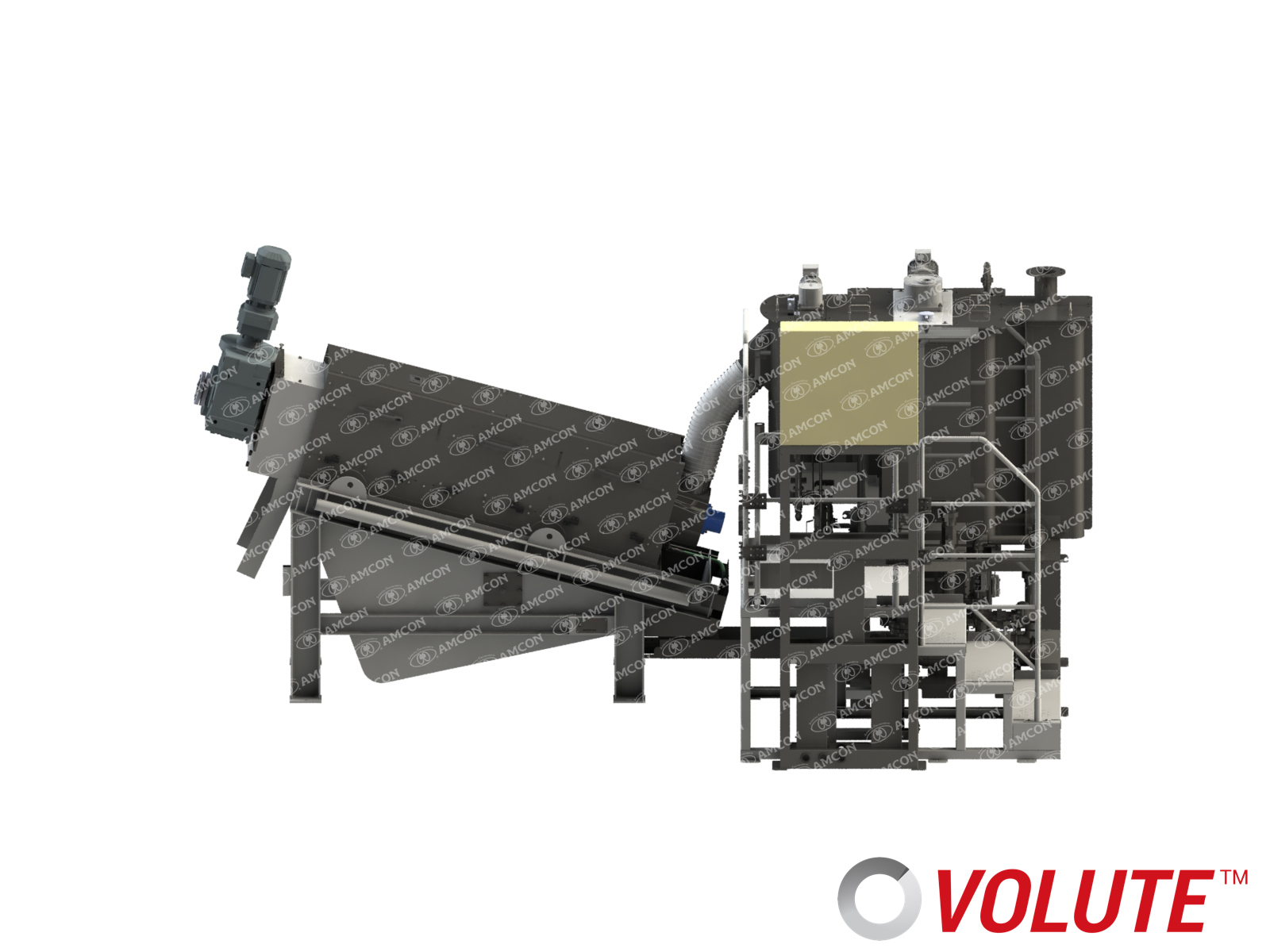

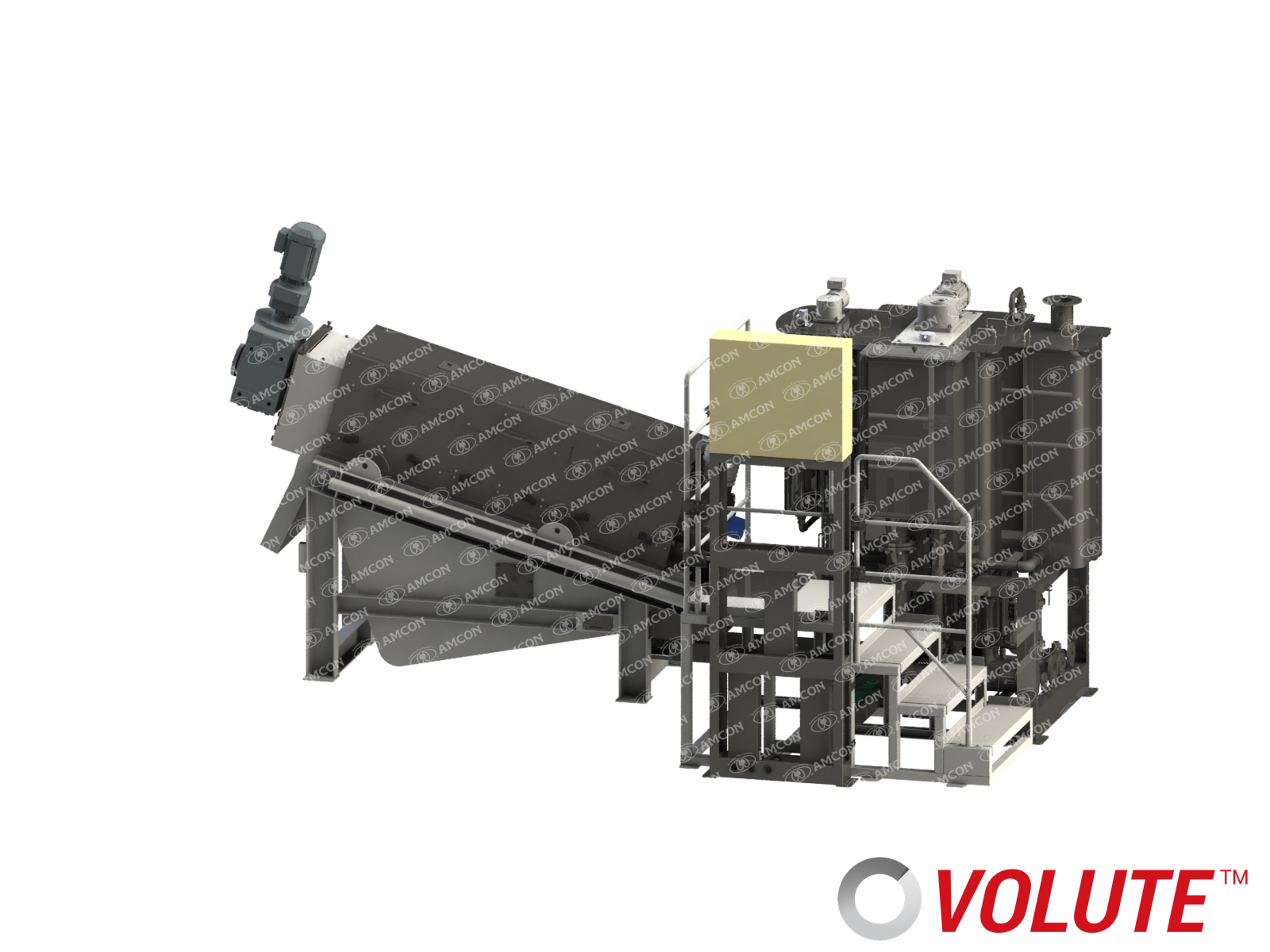

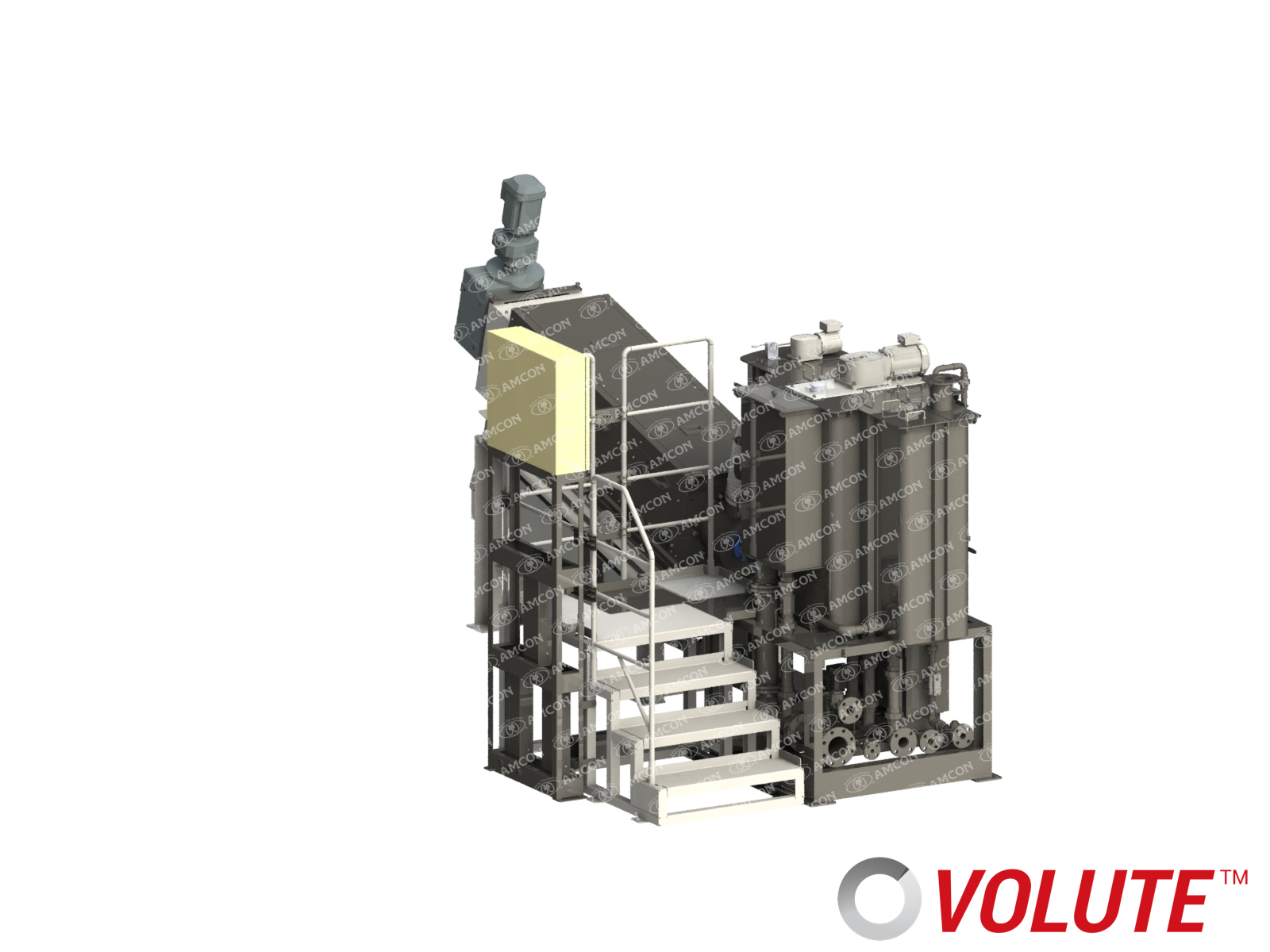

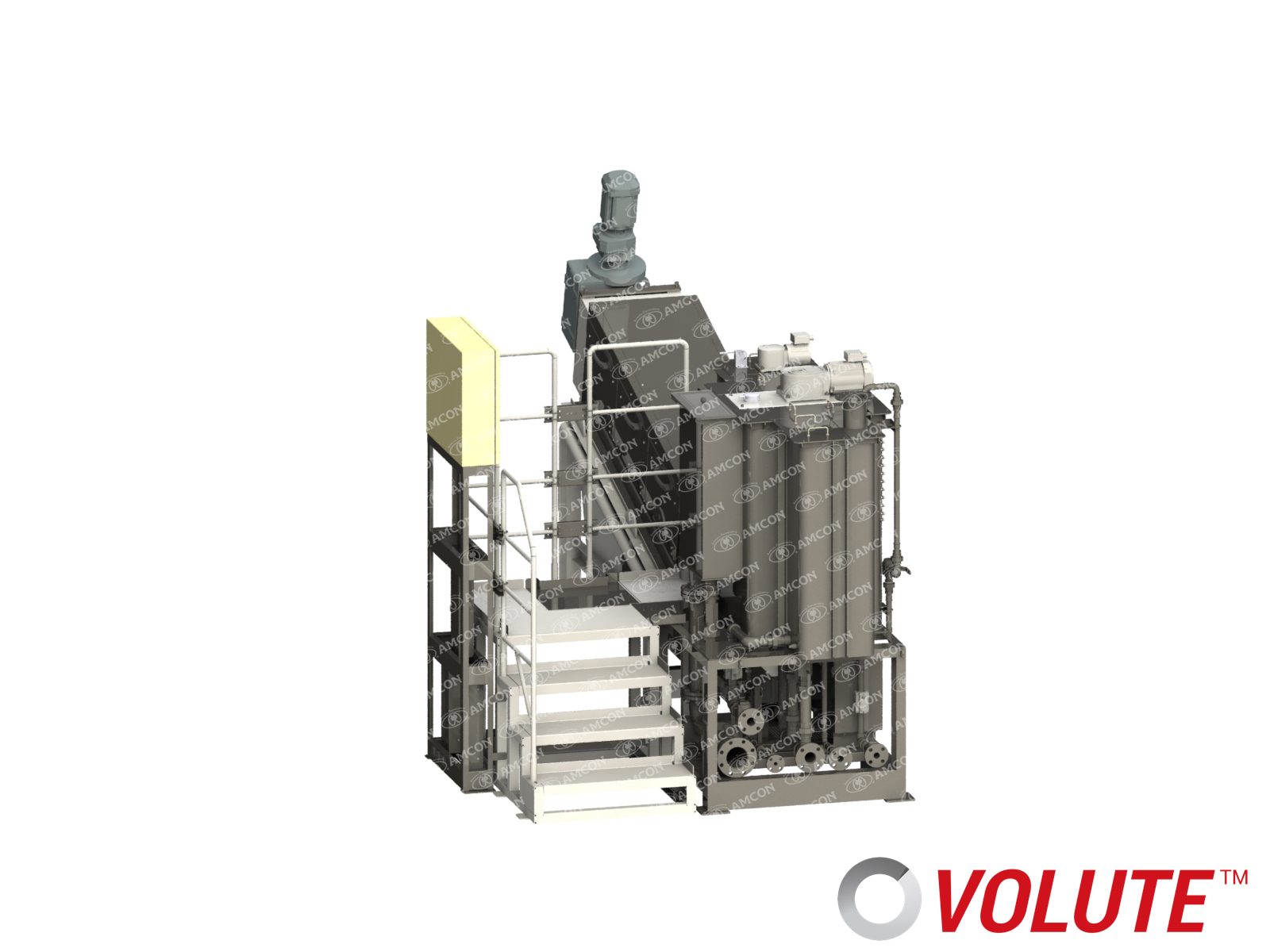

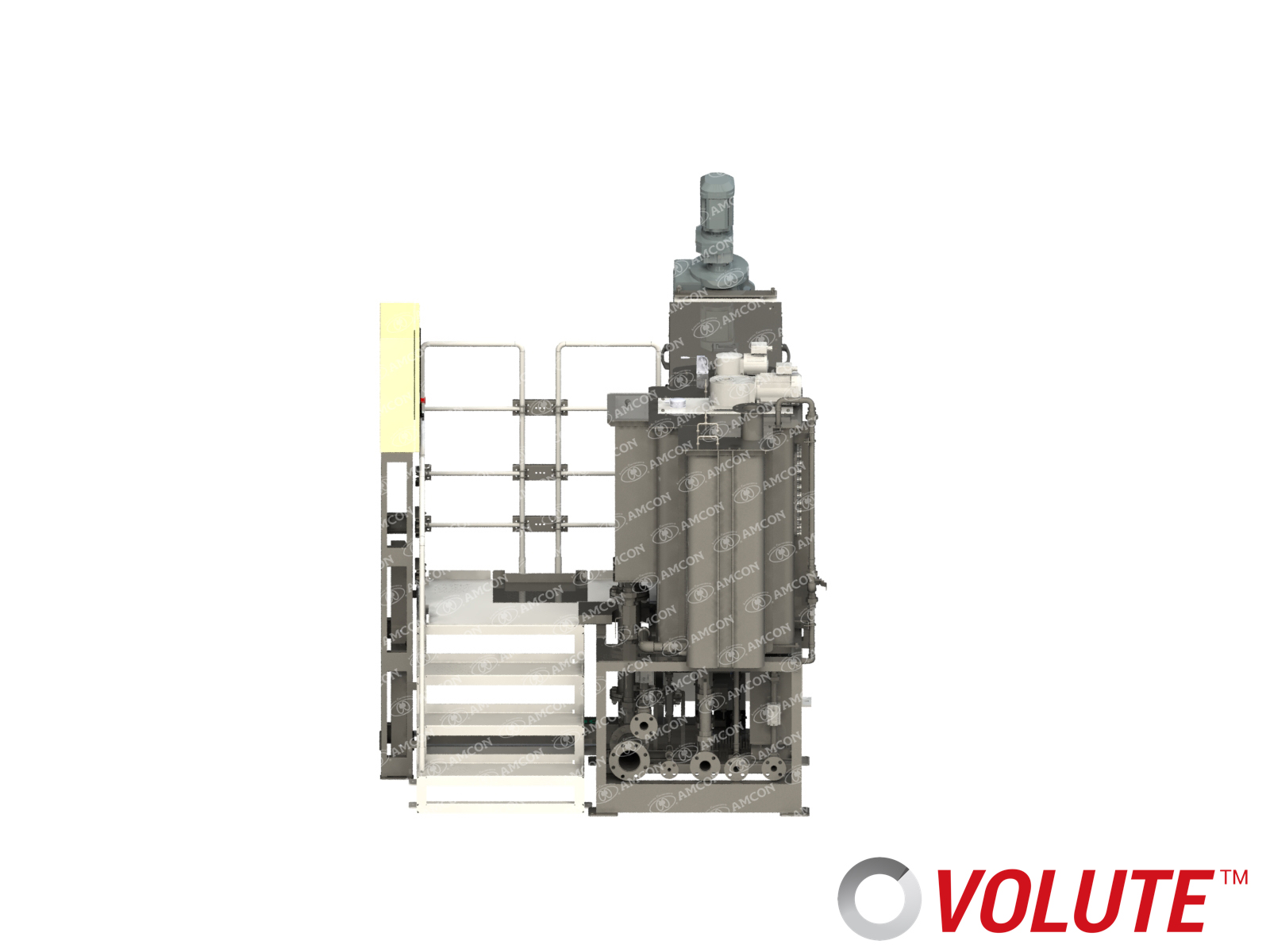

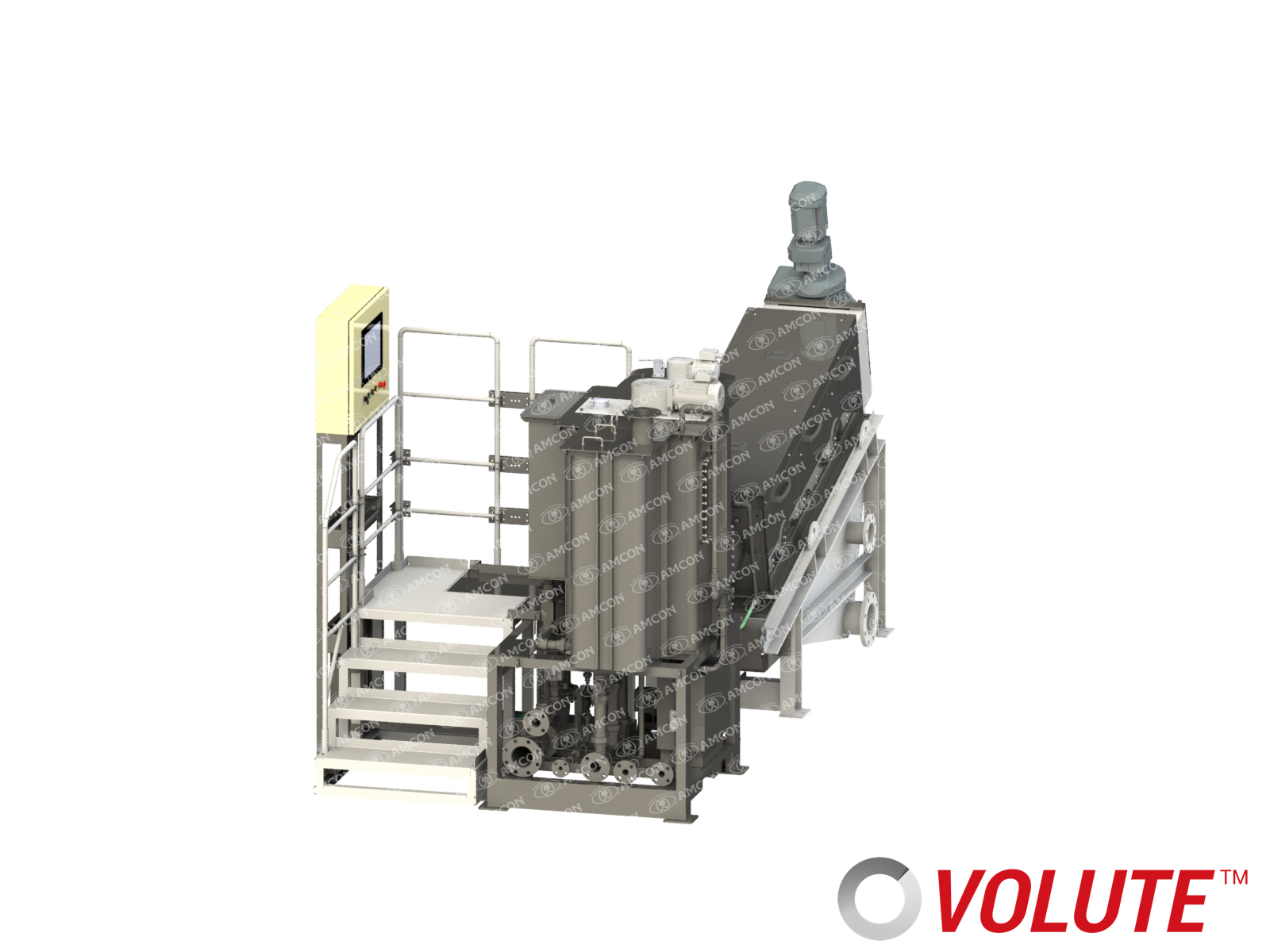

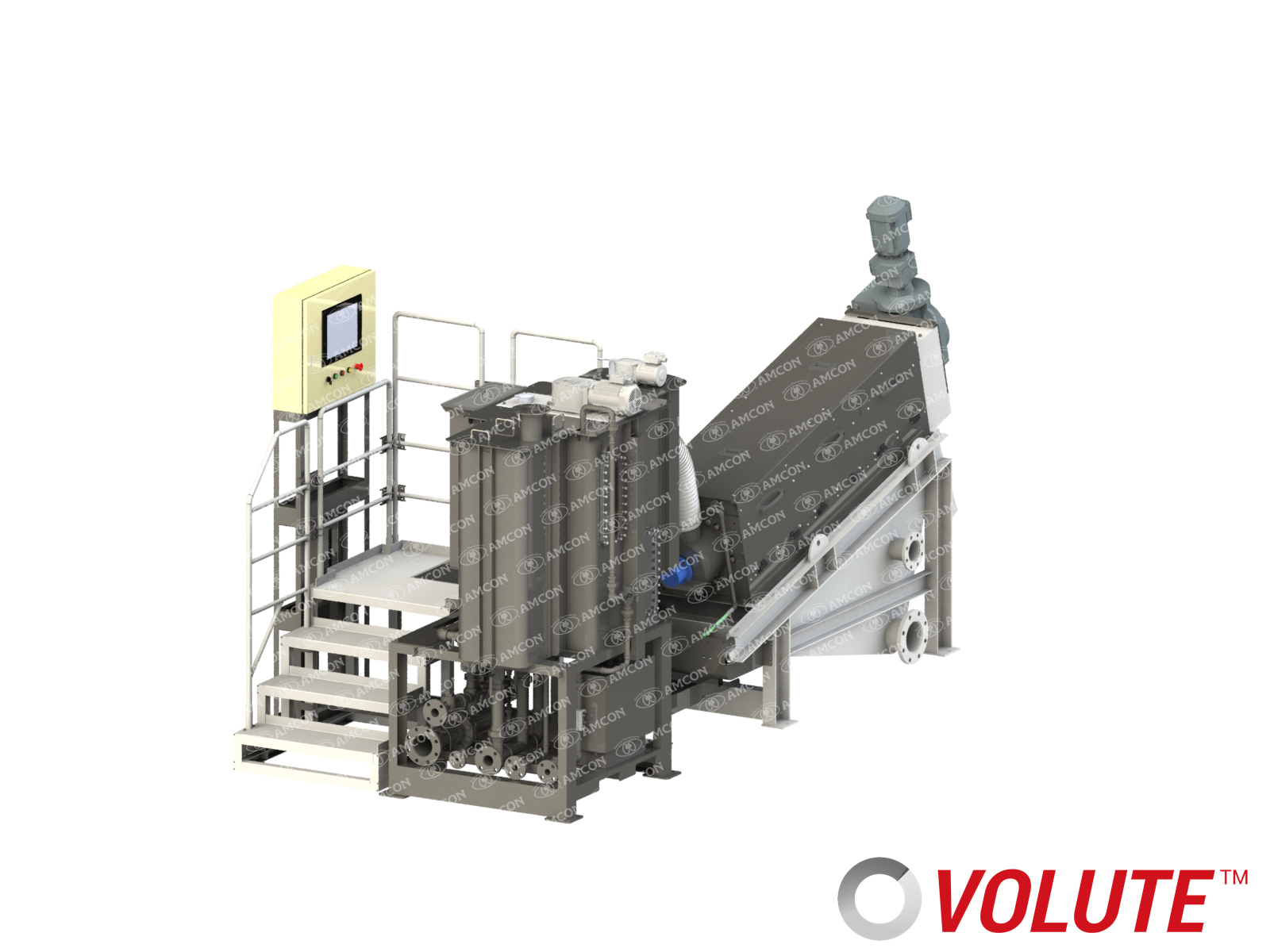

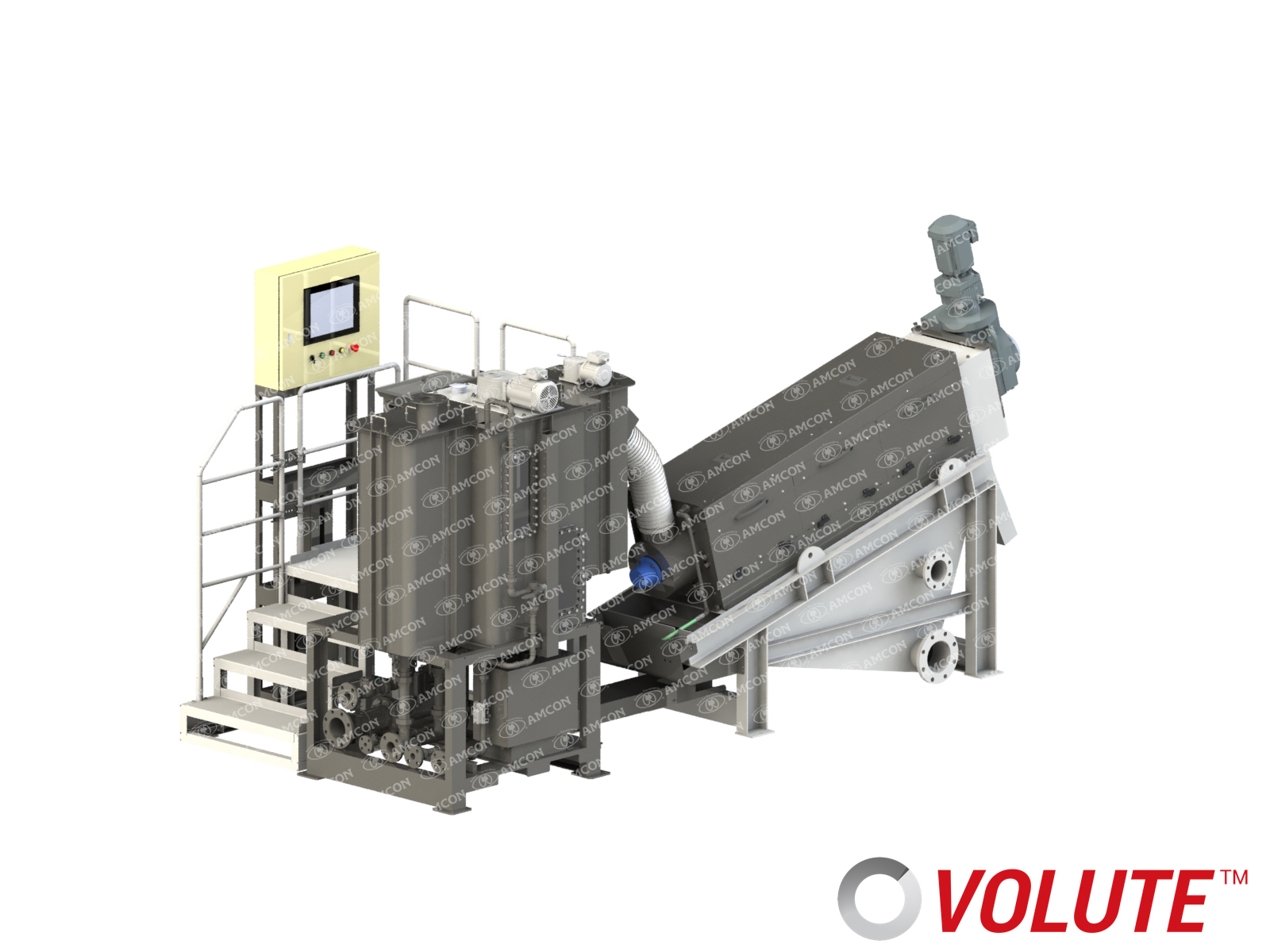

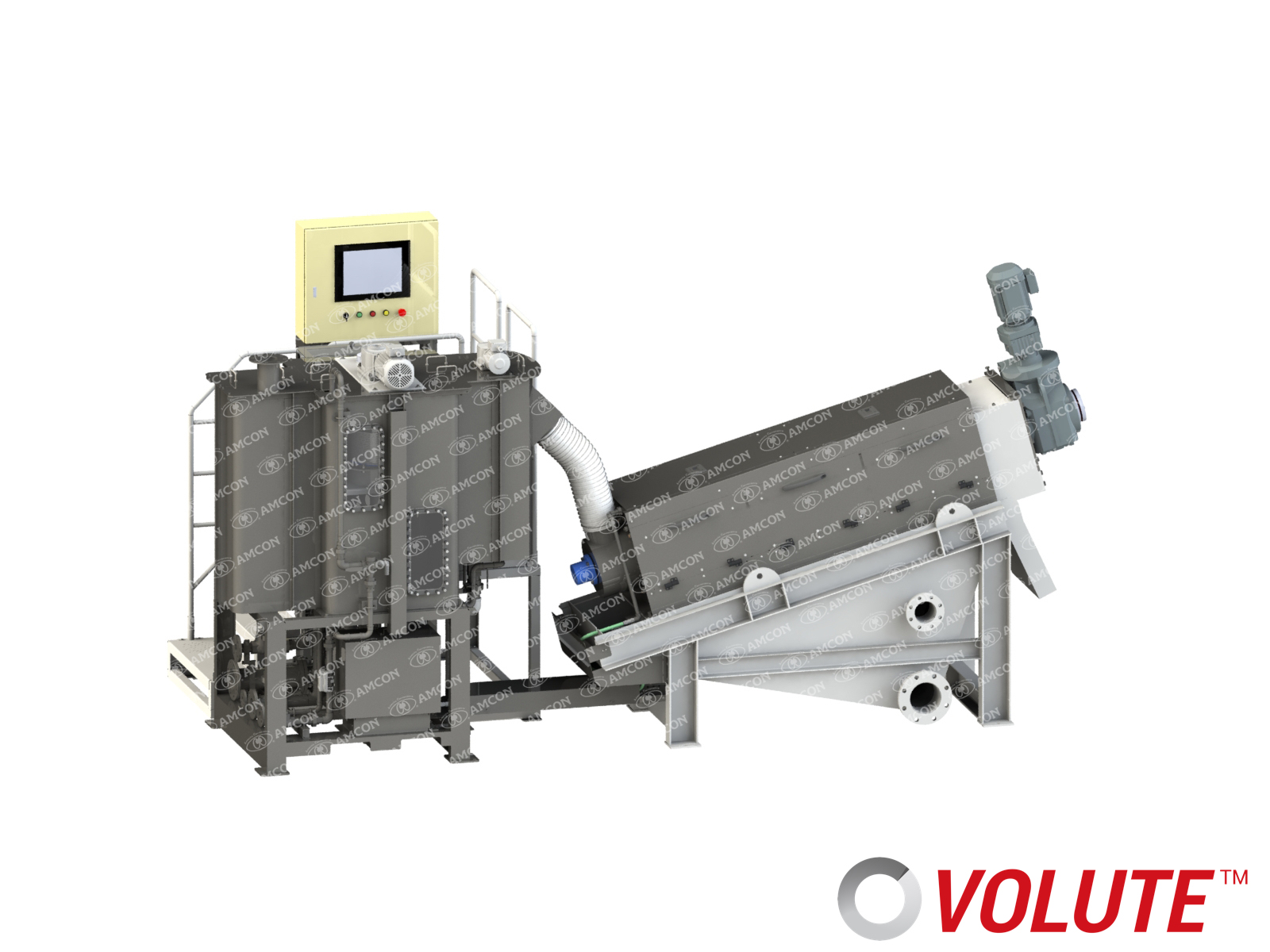

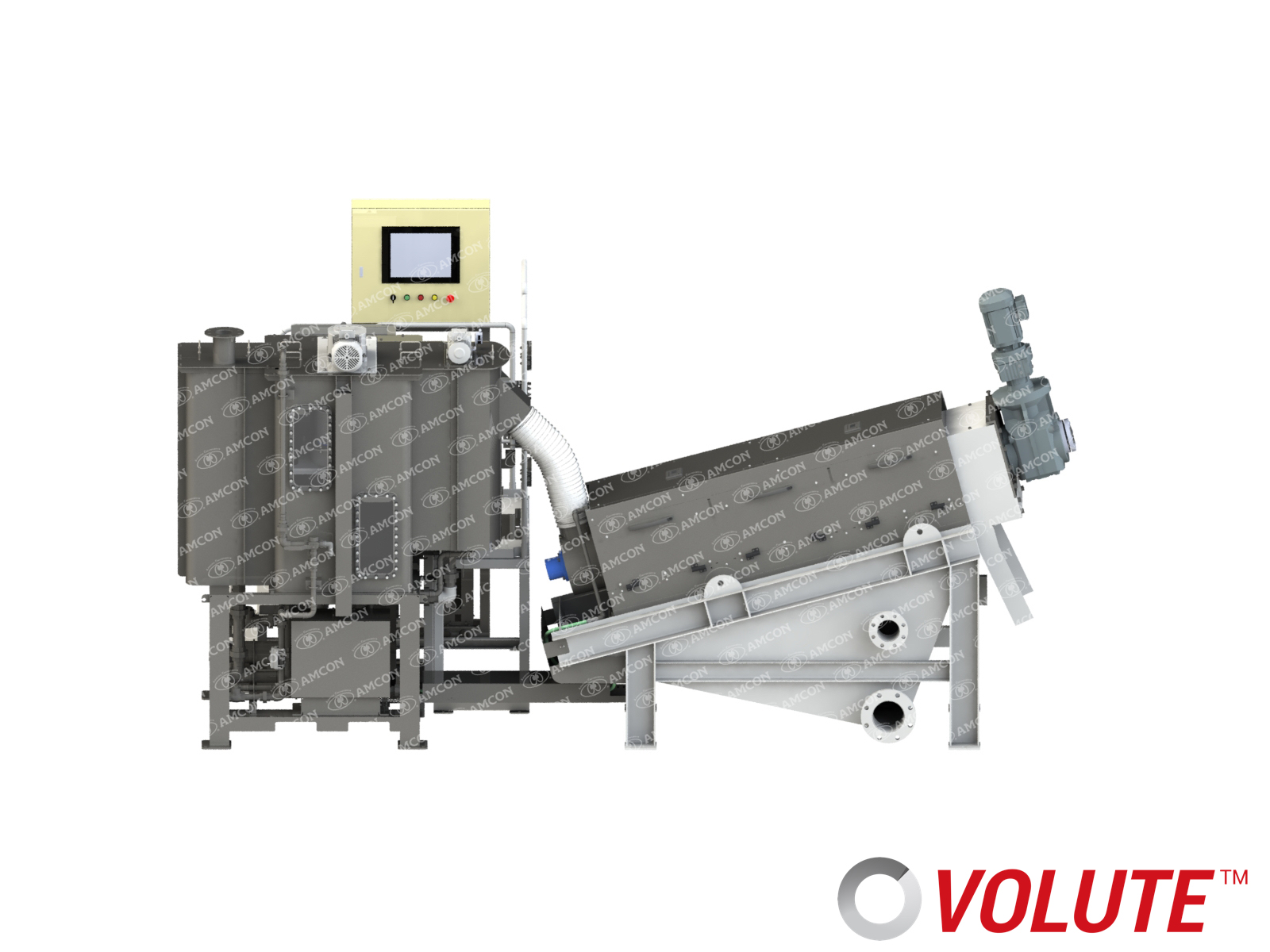

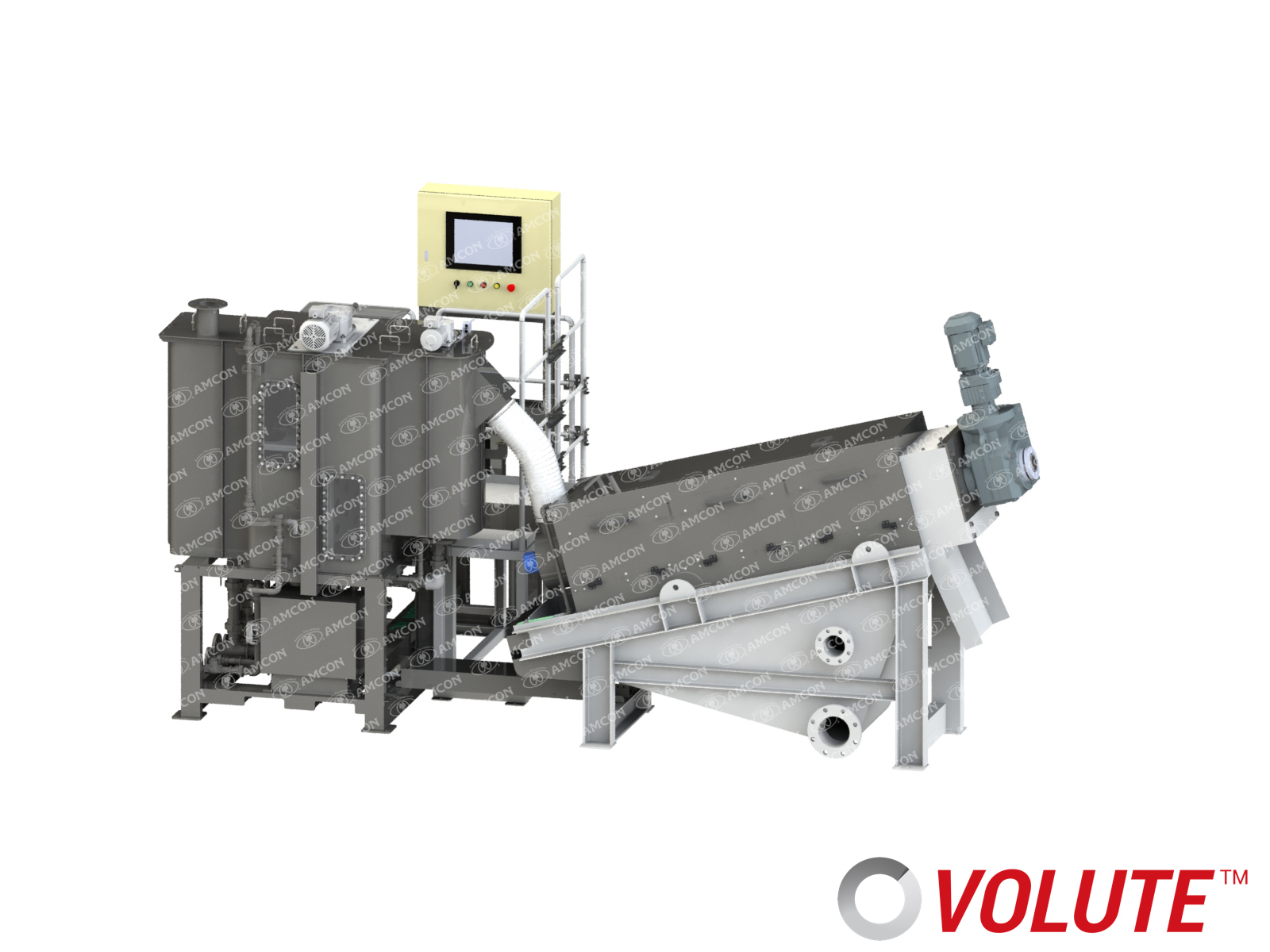

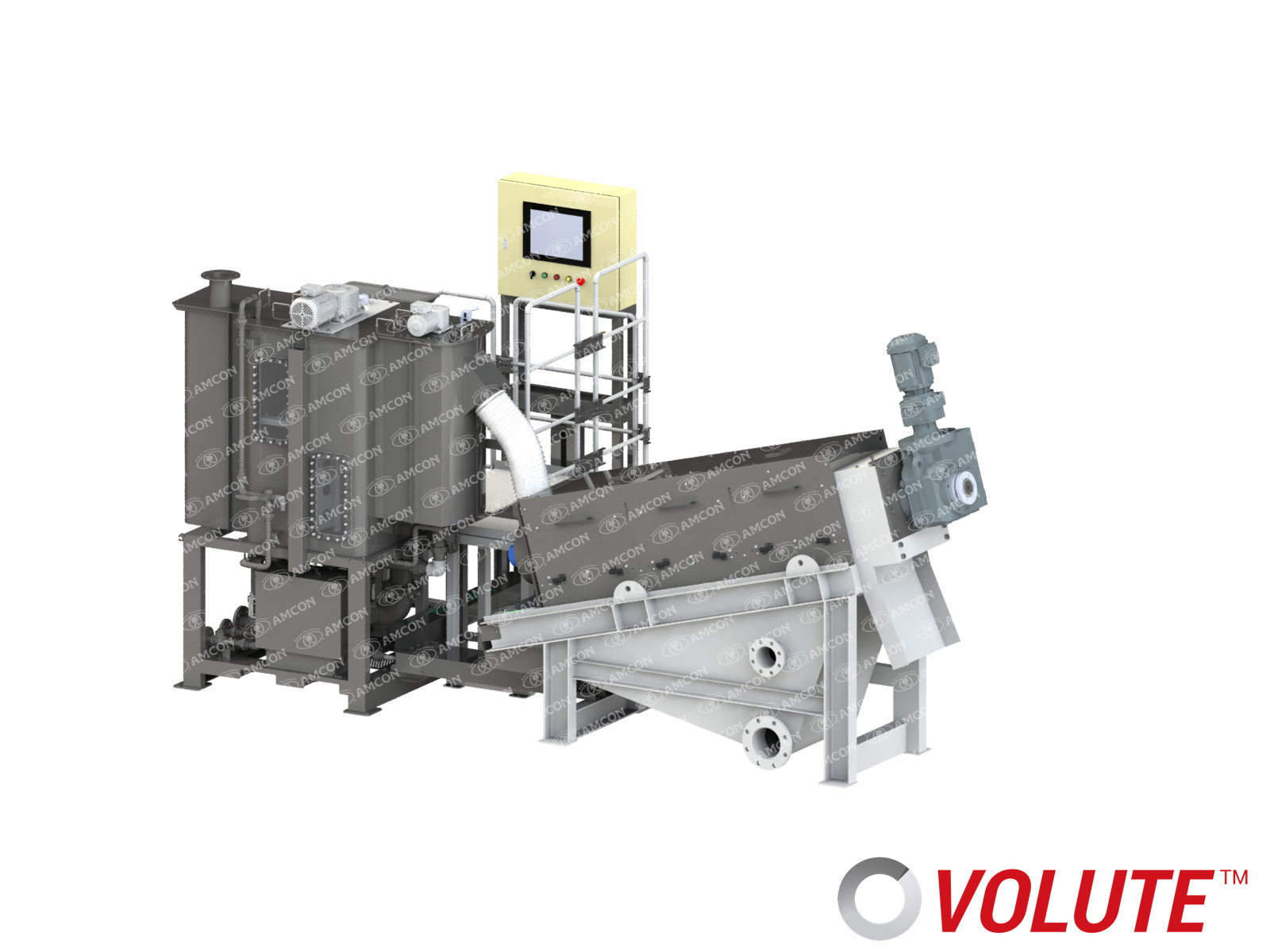

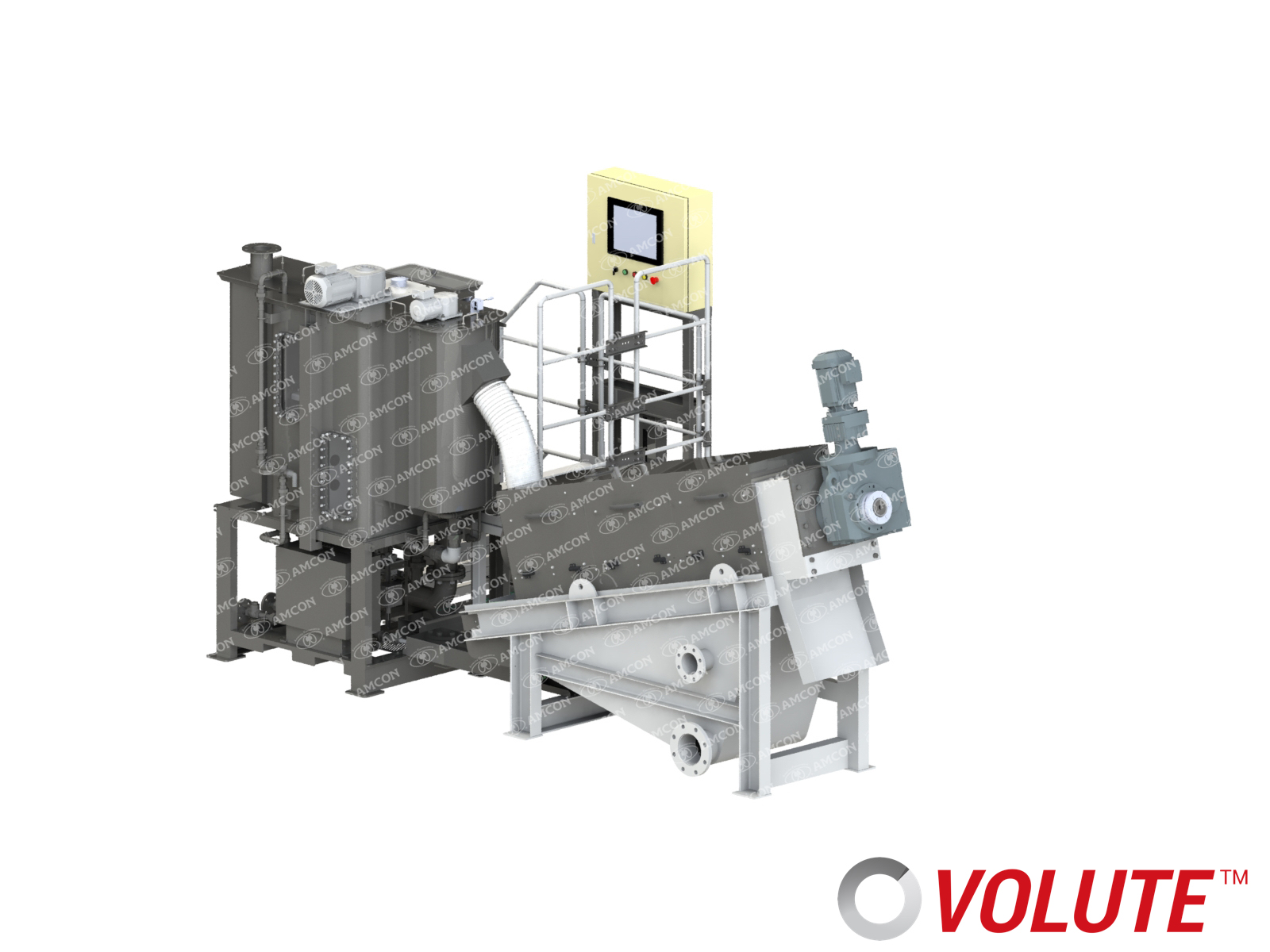

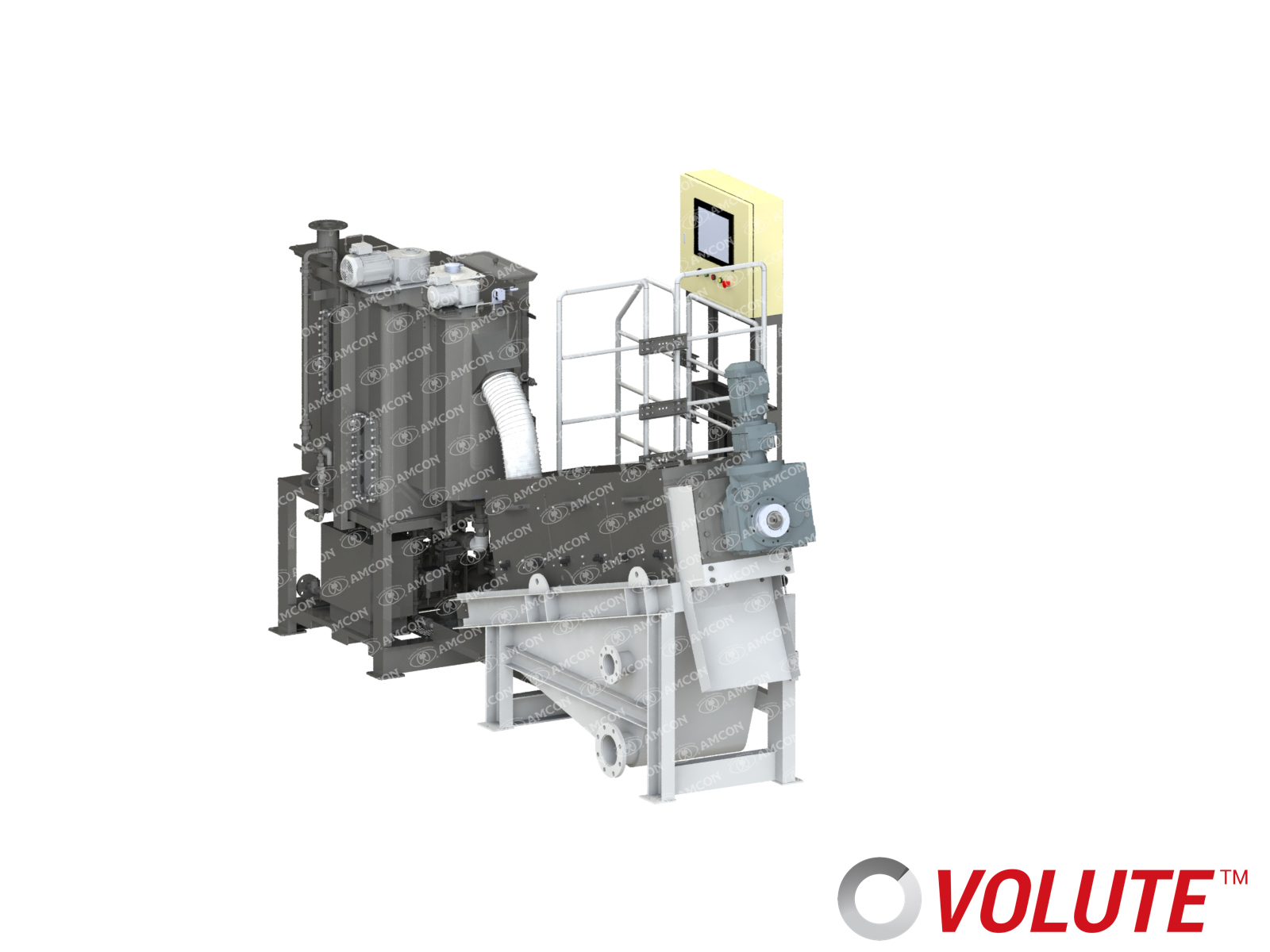

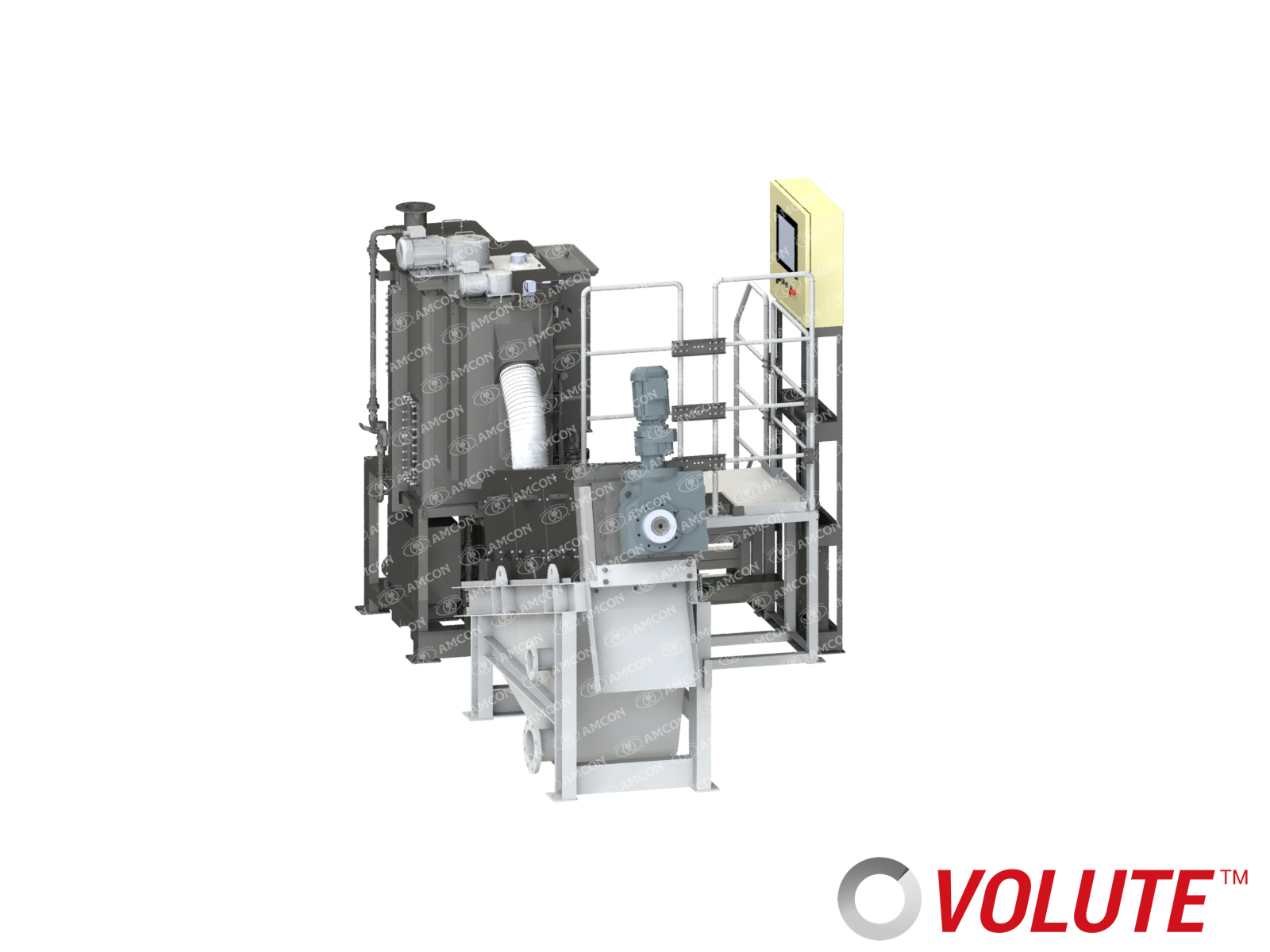

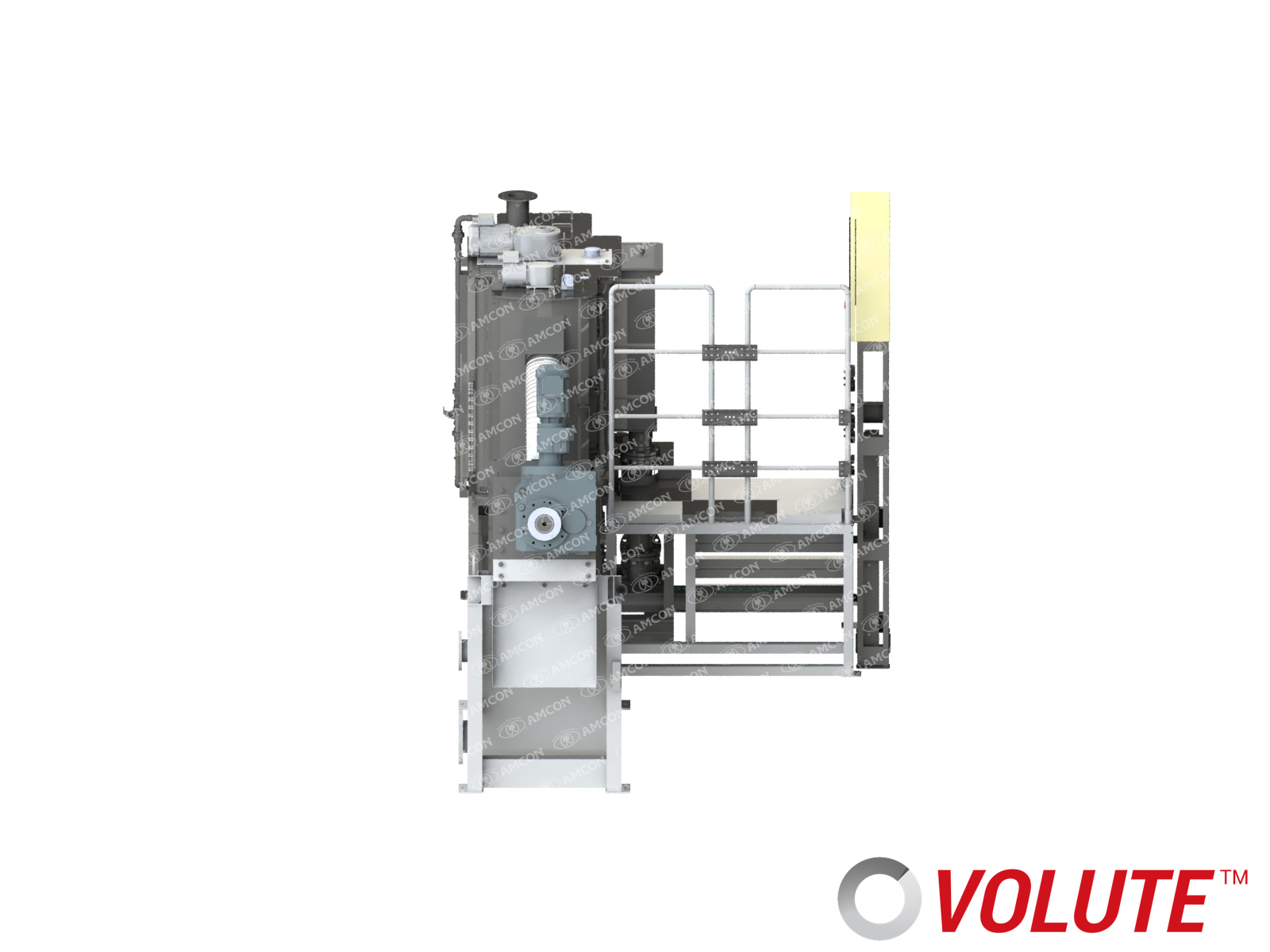

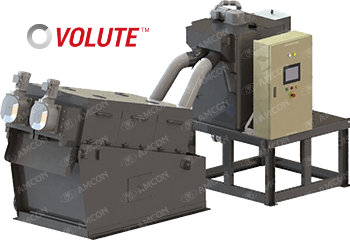

PROCESS FLOW

-

01

Thickening Flocculation Tank

Polymer and sluge are stirred and mixed, forming flocs suitable for VOLUTE™. Then, the built-in thickener in the tank instantly thicken the sludge. -

02

Reactor Tank for Coagulant

Coagulant is added to the concentrated sludge, and mixe in this tank. -

03

Cylinder Unit

Sludge is further thickened in the thickening zone of the cylinder, and then the inner pressure increased at the dewatering zone helps sludge being dewatered well. -

04

Discharge Outlet for Dewatering Cake

Further pressure is applied from the outlet side with the End Plate, discharging dewatered cake with around 30% dry solids content.

RENTAL

Flow for Product Installation