ADVANTAGES

-

No clogging even with oily sludge

No clogging even with oily sludge -

Applicable for various applications

Applicable for various applications -

High solid capture rate

High solid capture rate -

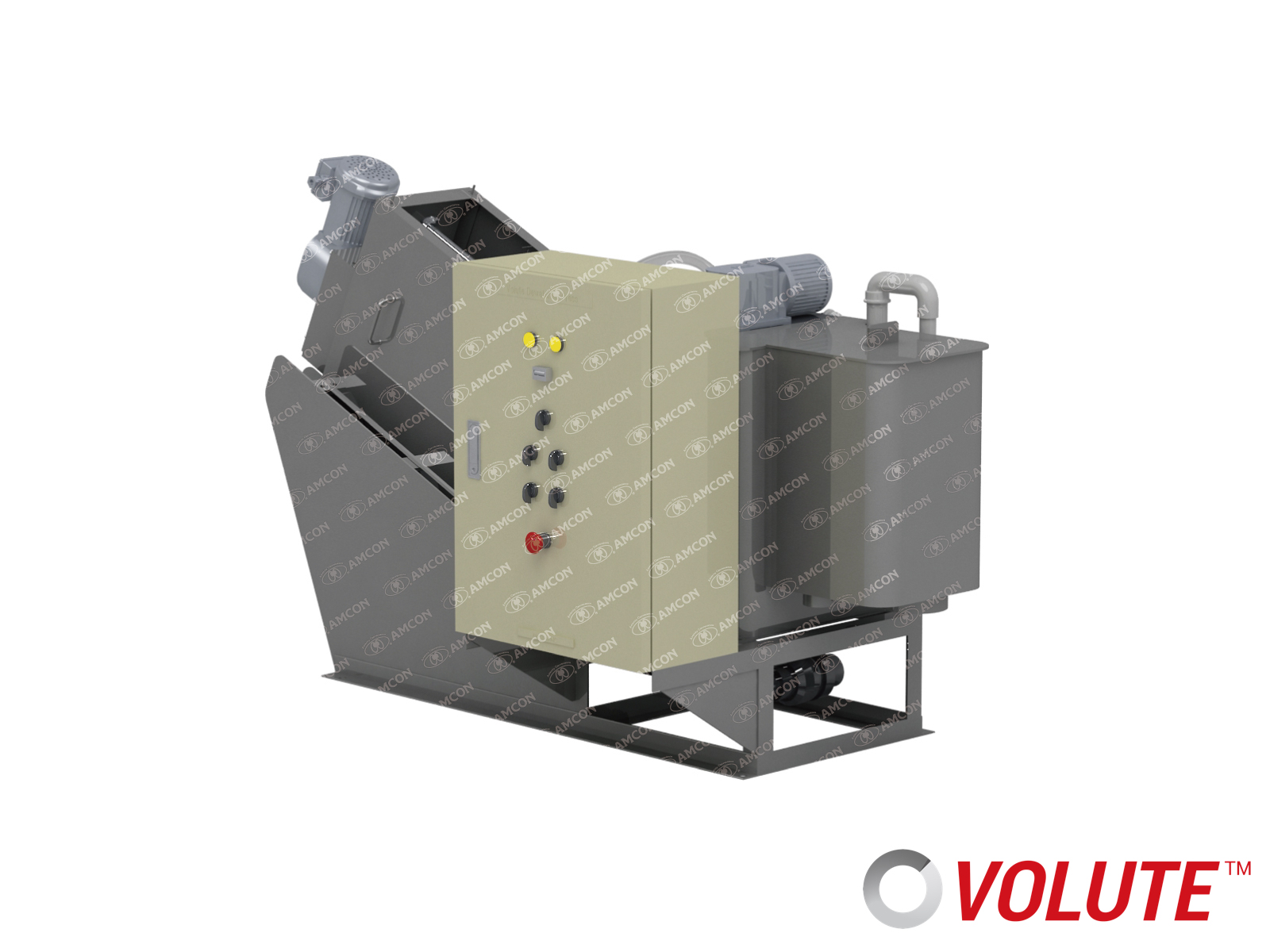

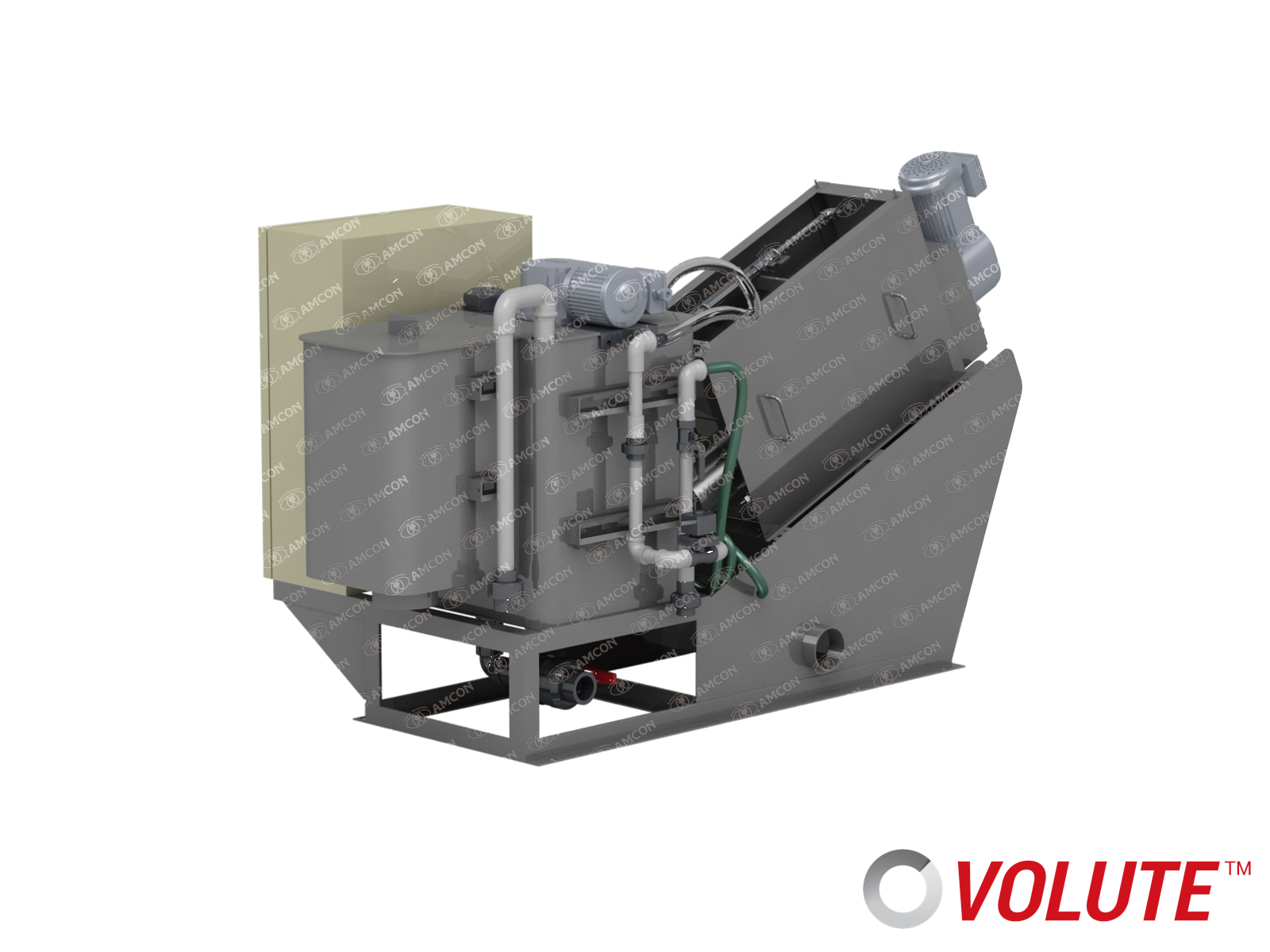

Power-saving

Power-saving -

Water-saving

Water-saving -

Low noise and low vibration

Low noise and low vibration -

Easy operation and easy maintenance

Easy operation and easy maintenance -

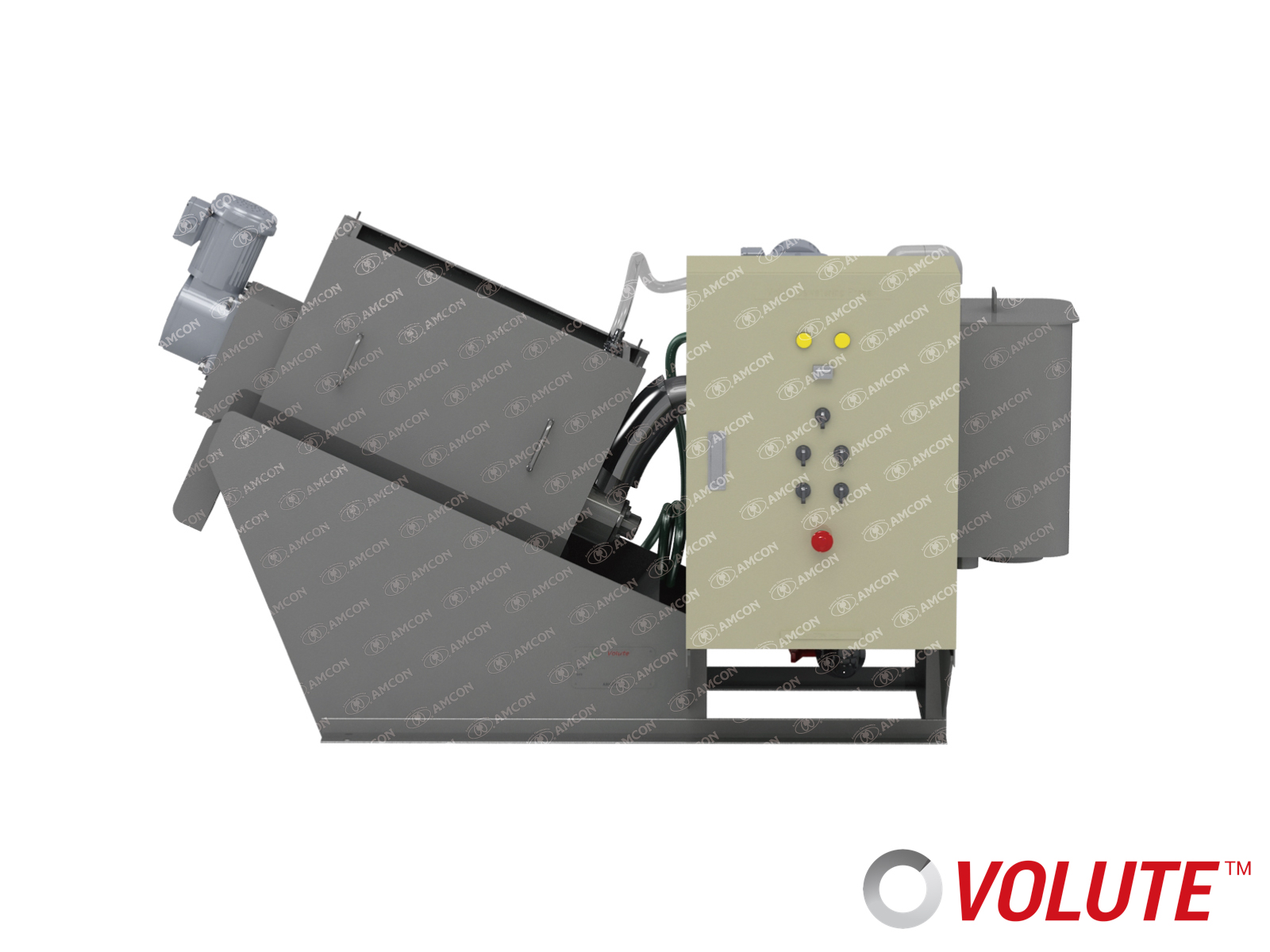

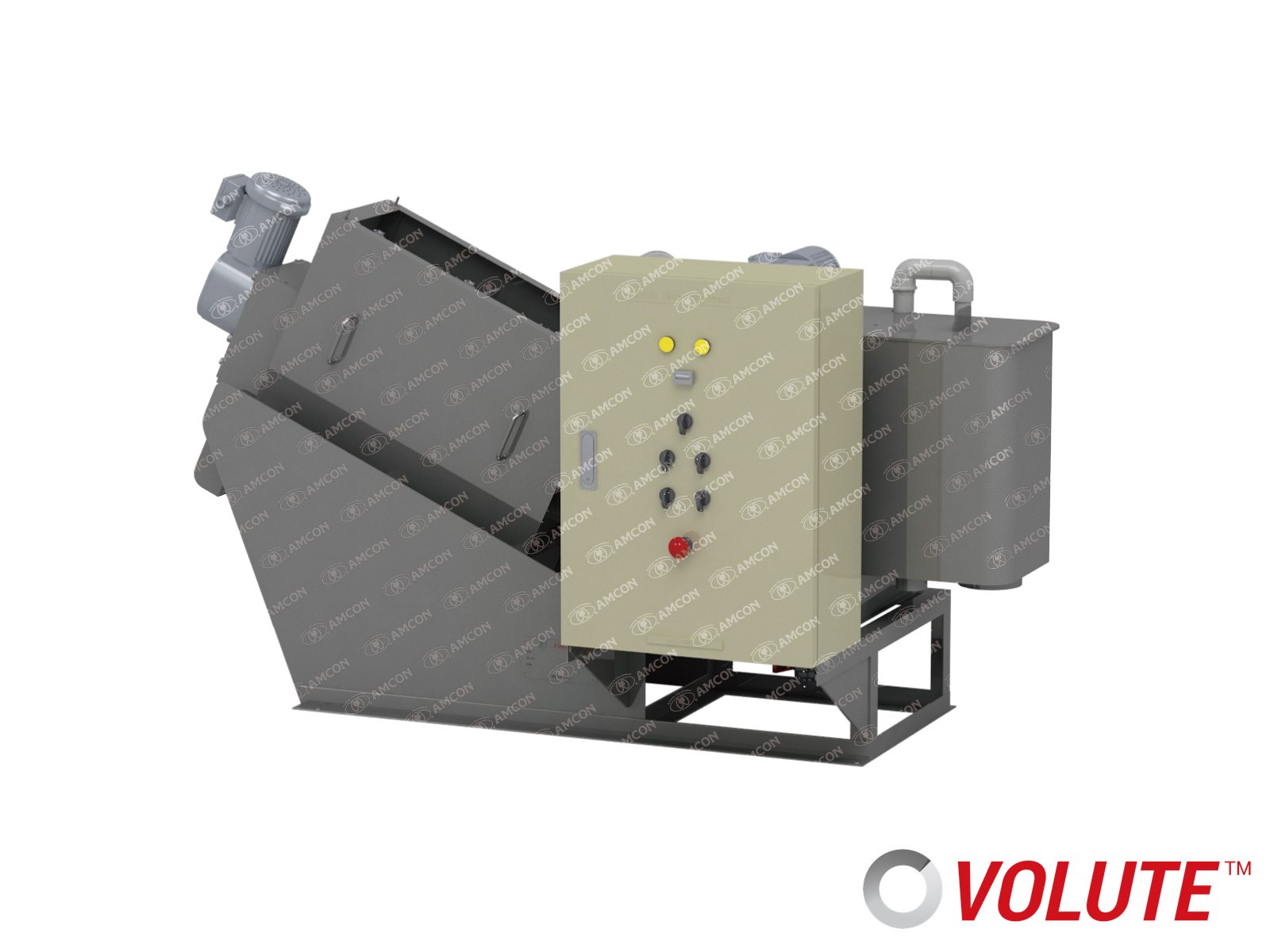

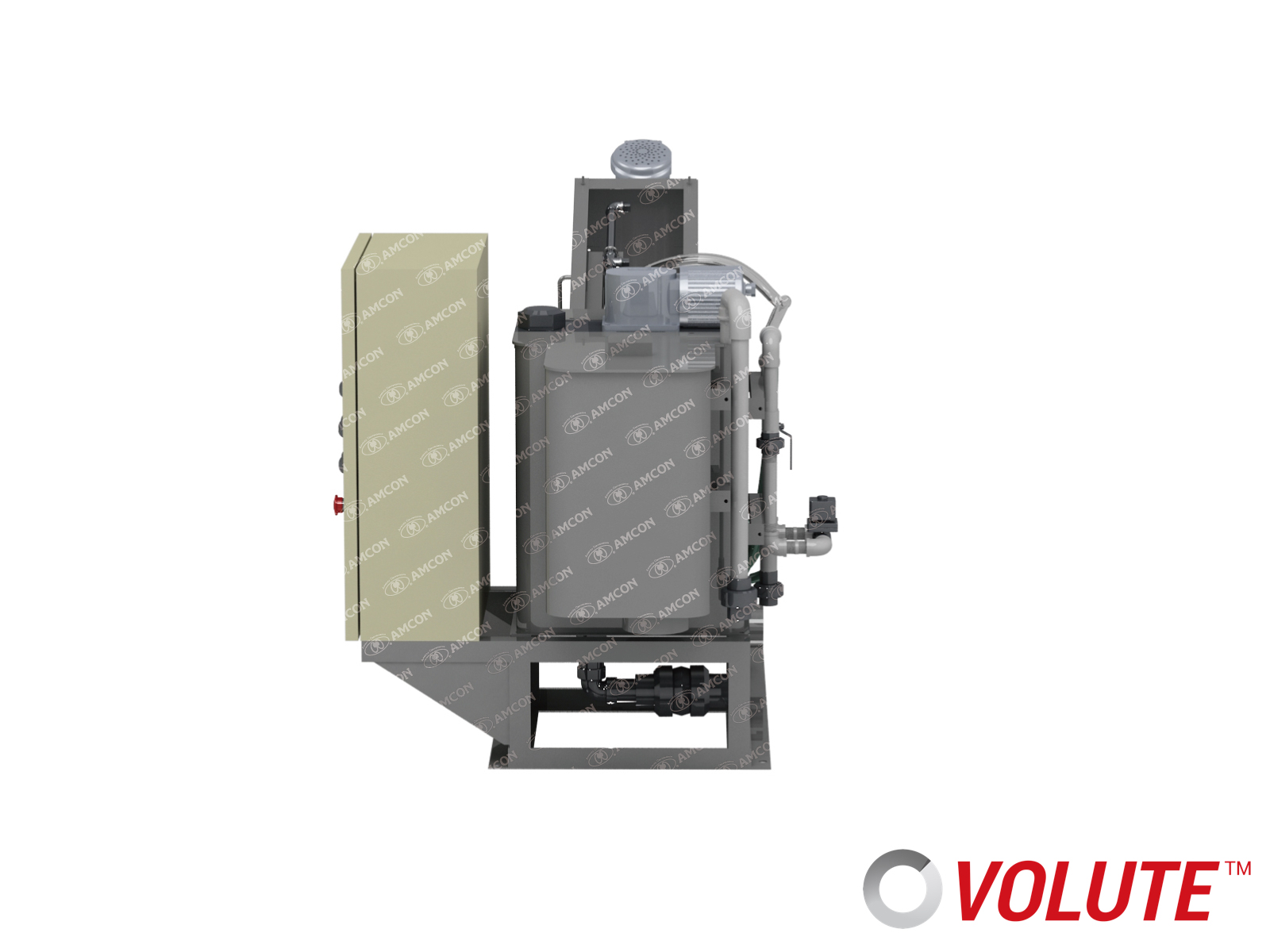

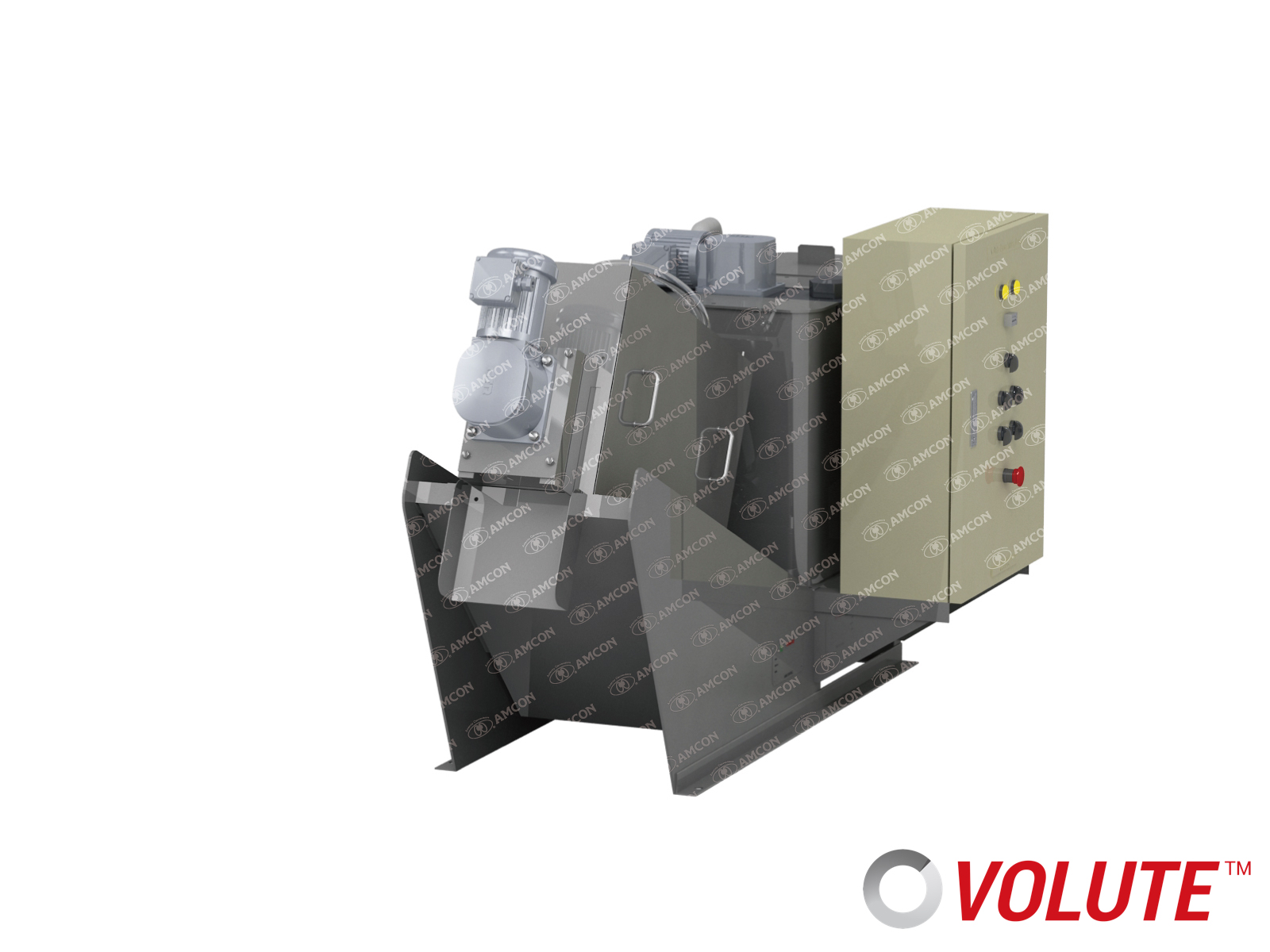

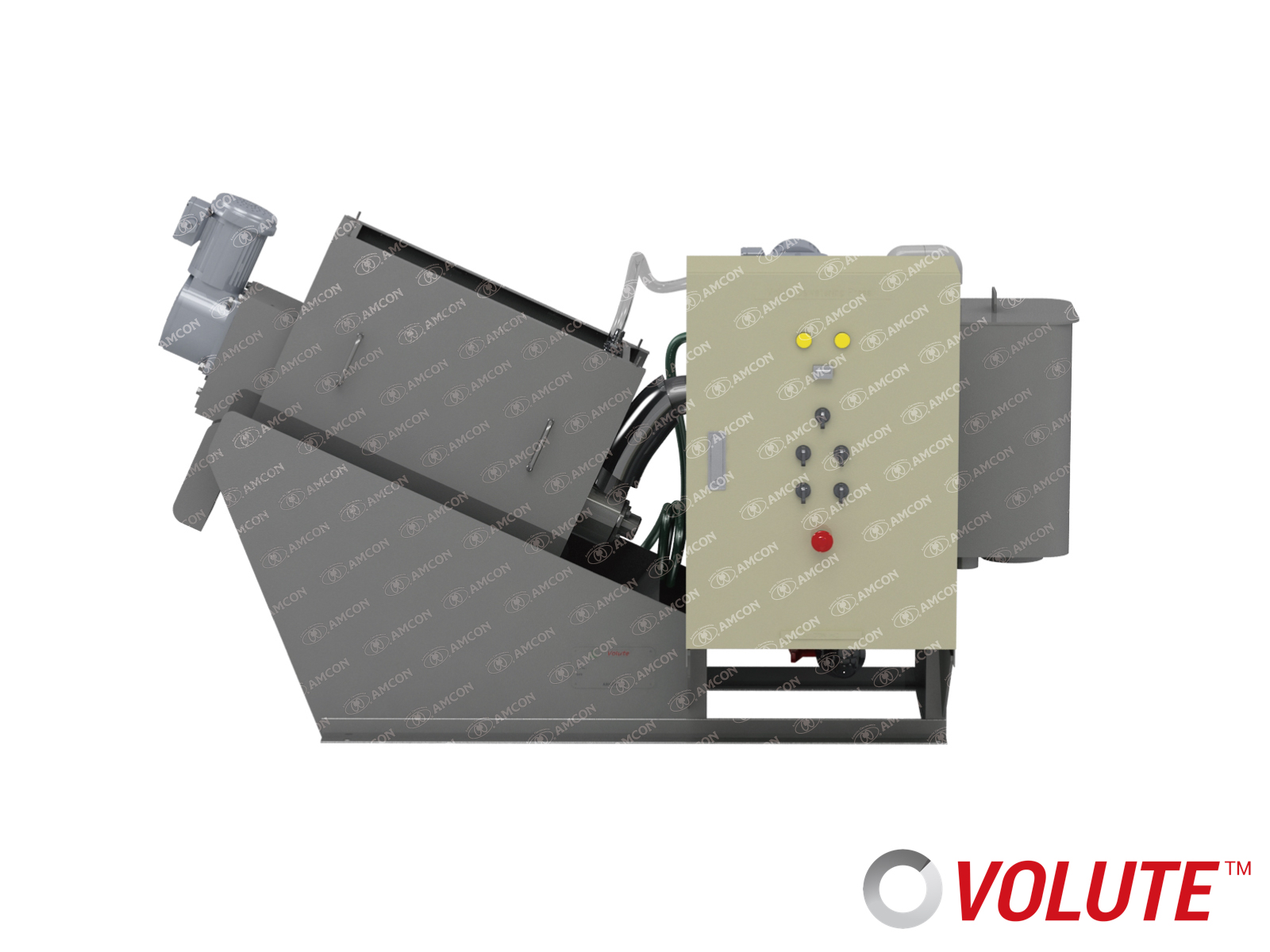

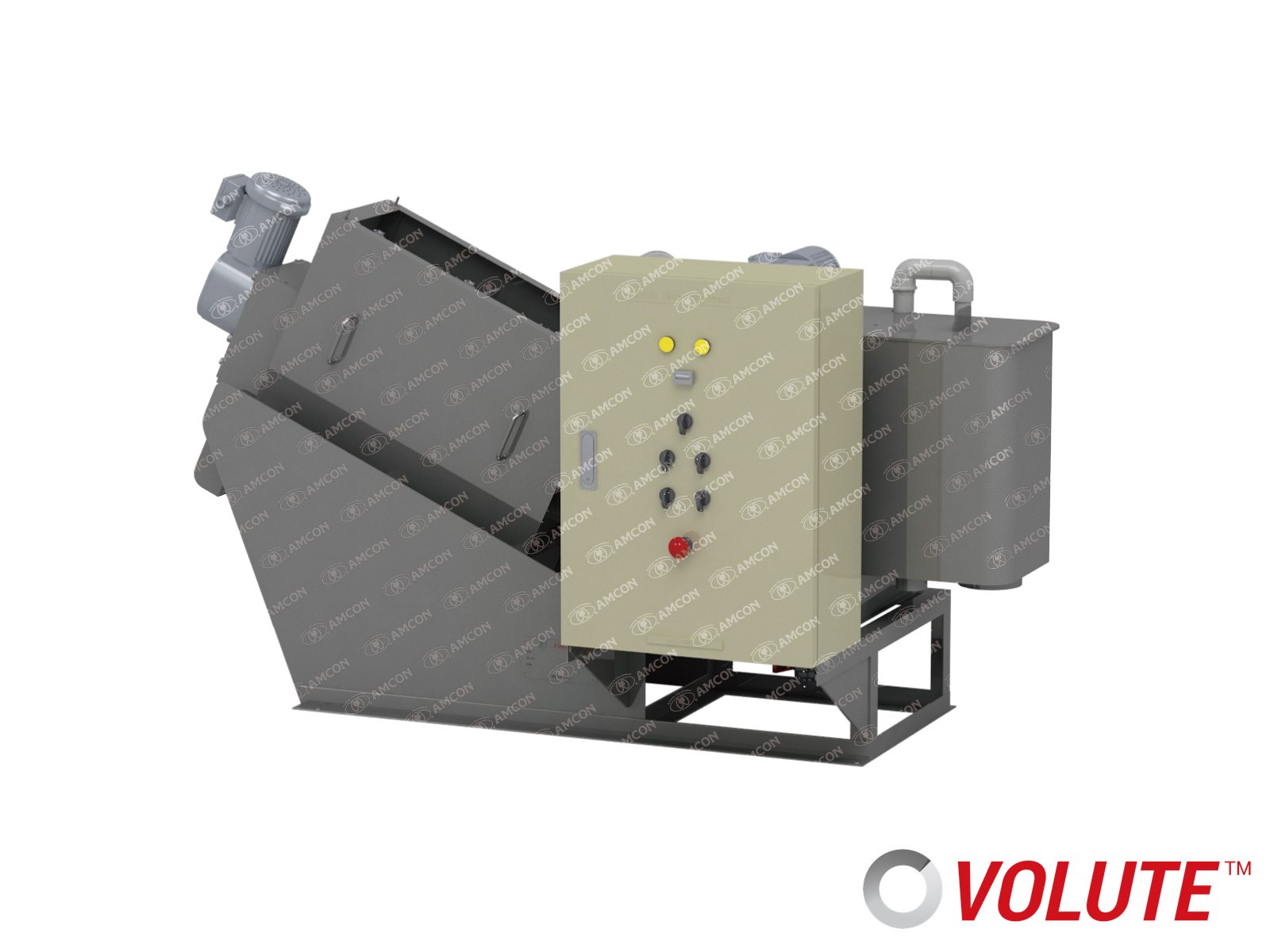

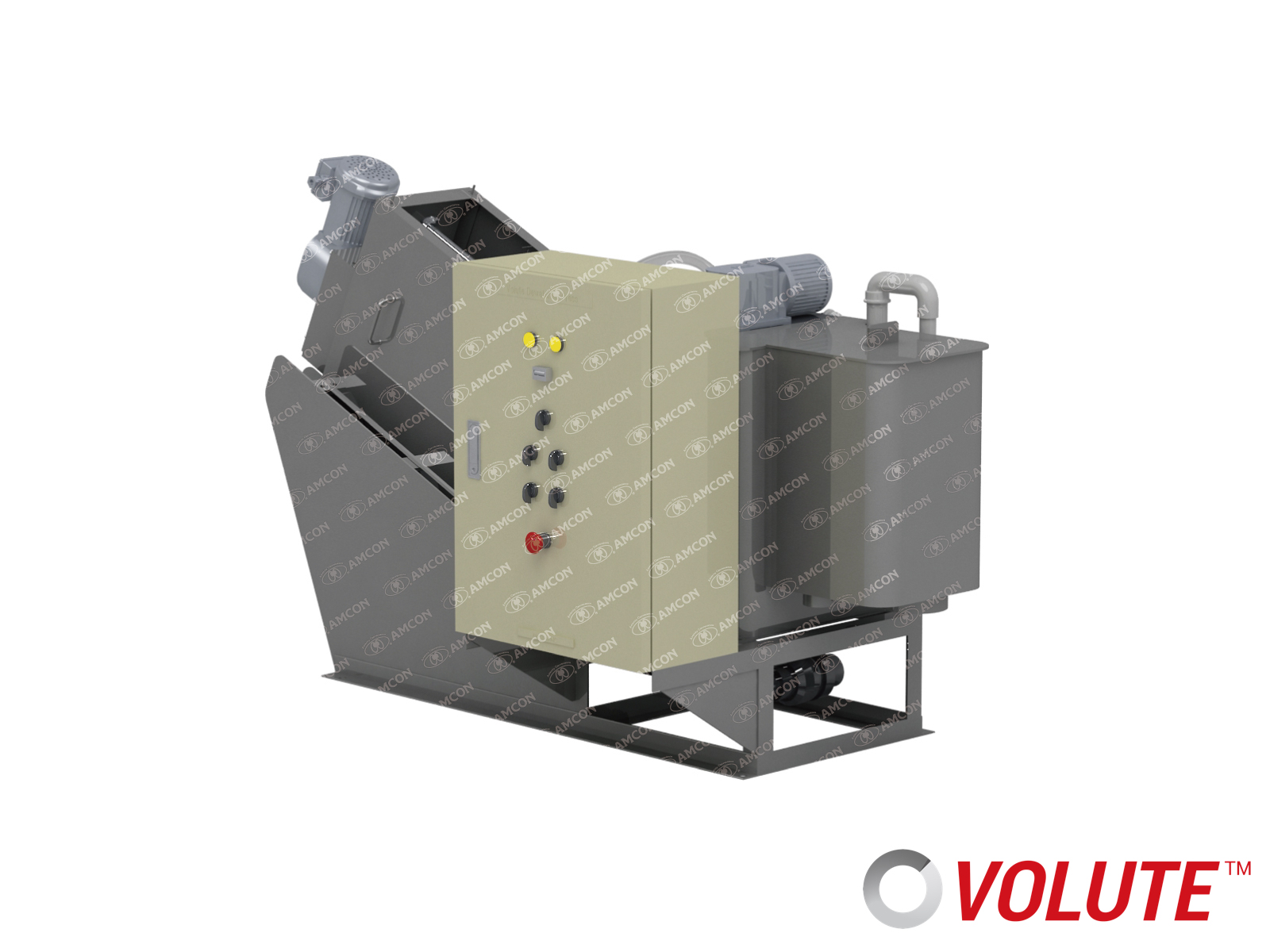

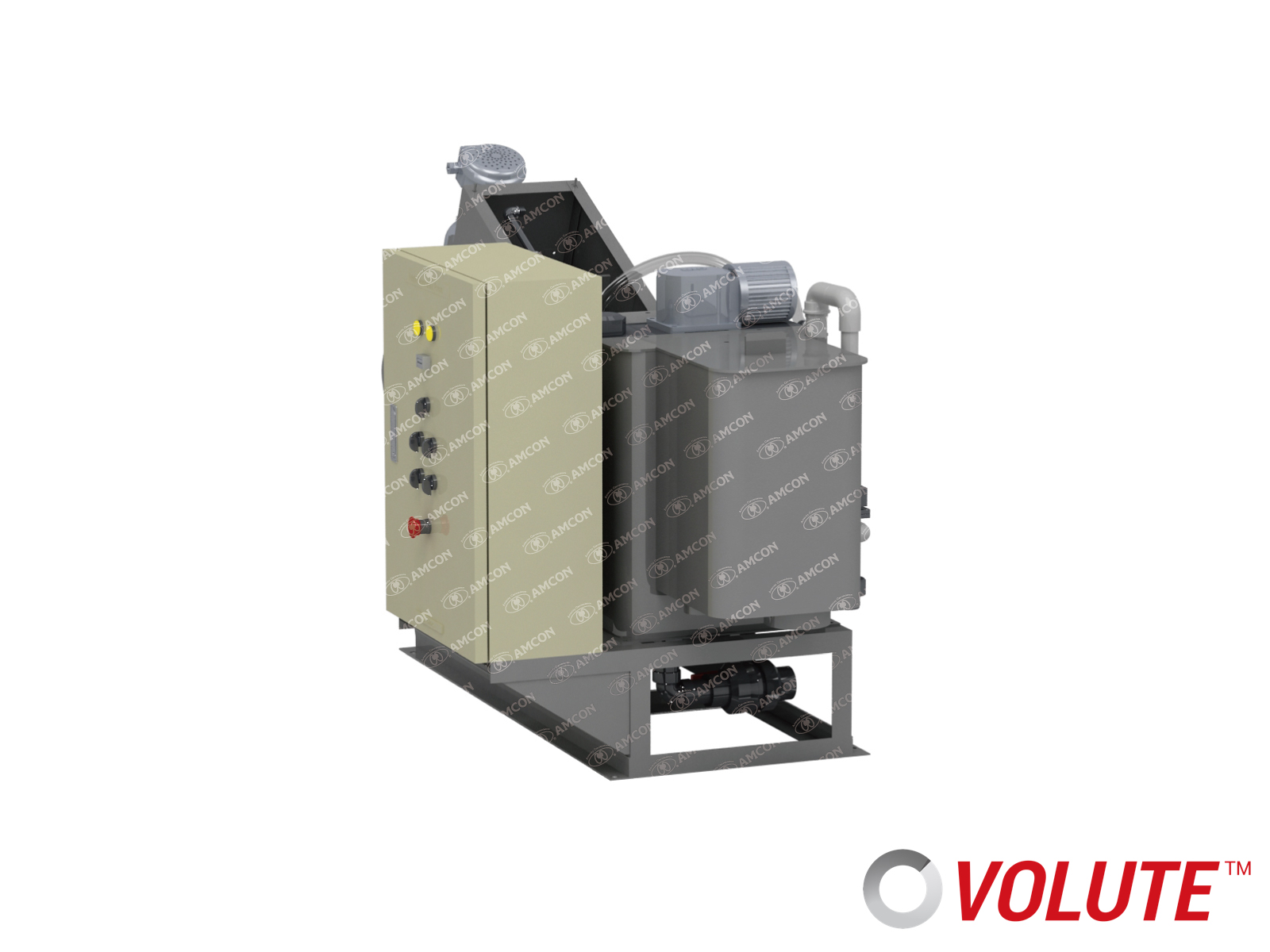

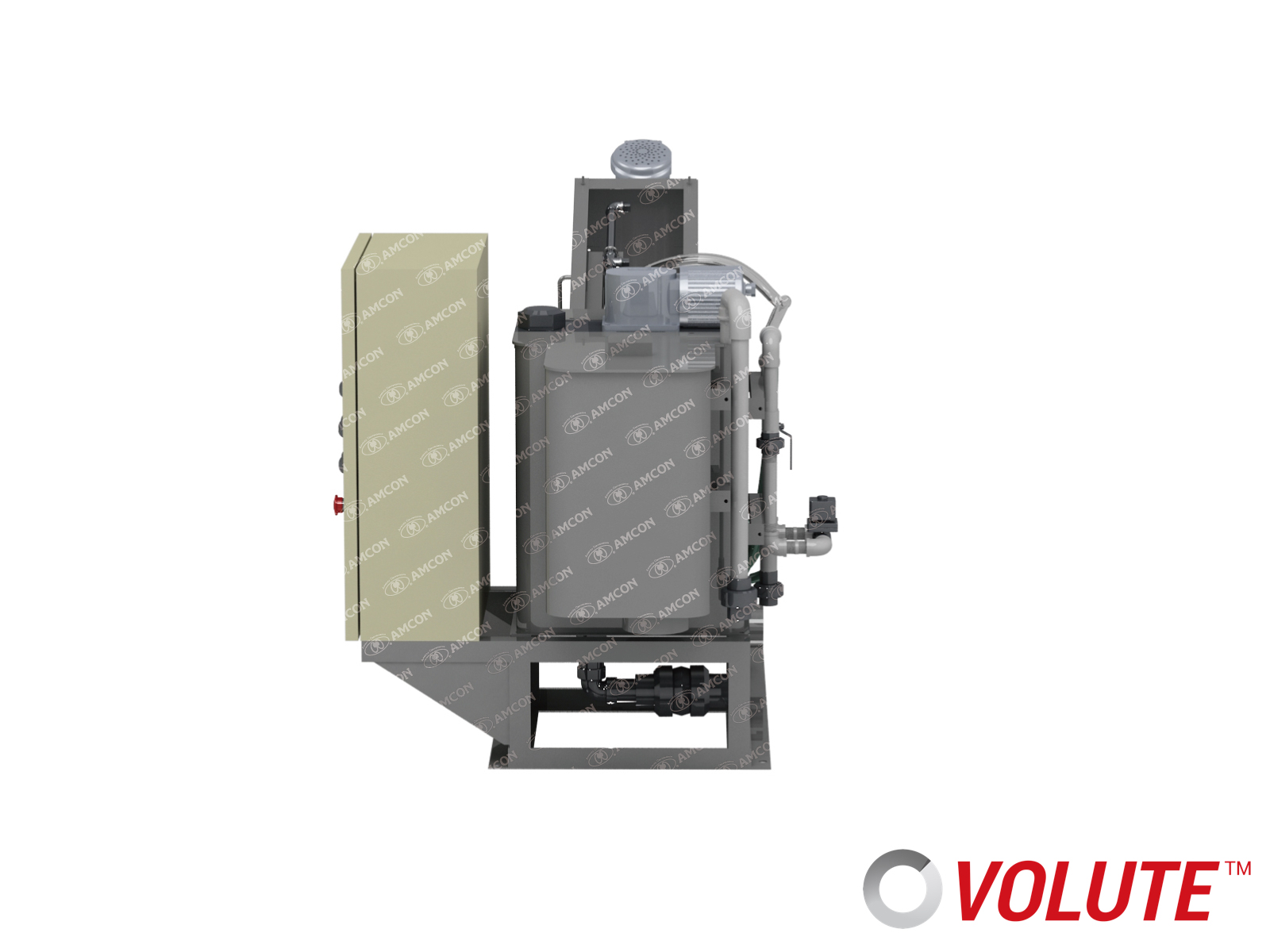

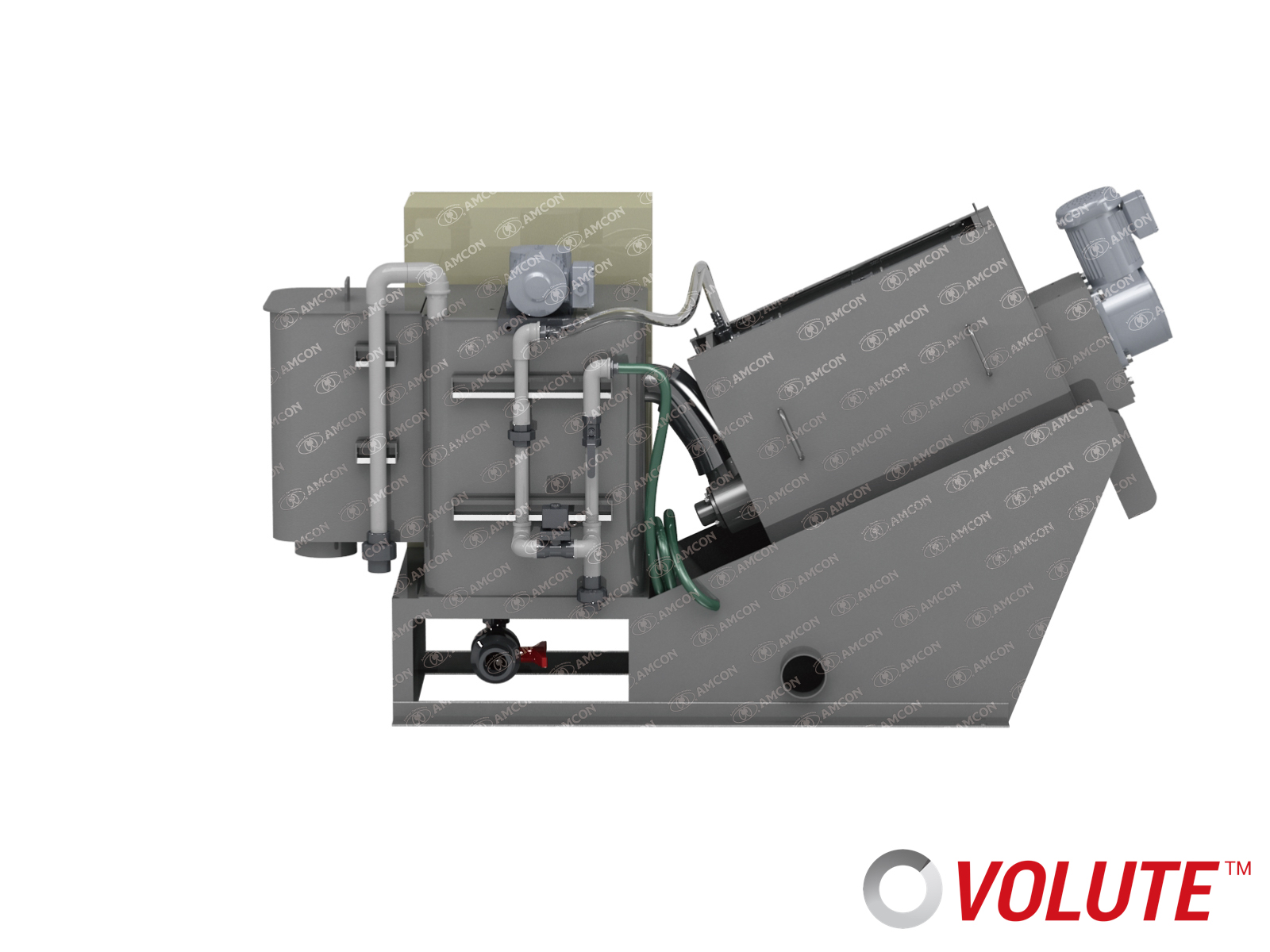

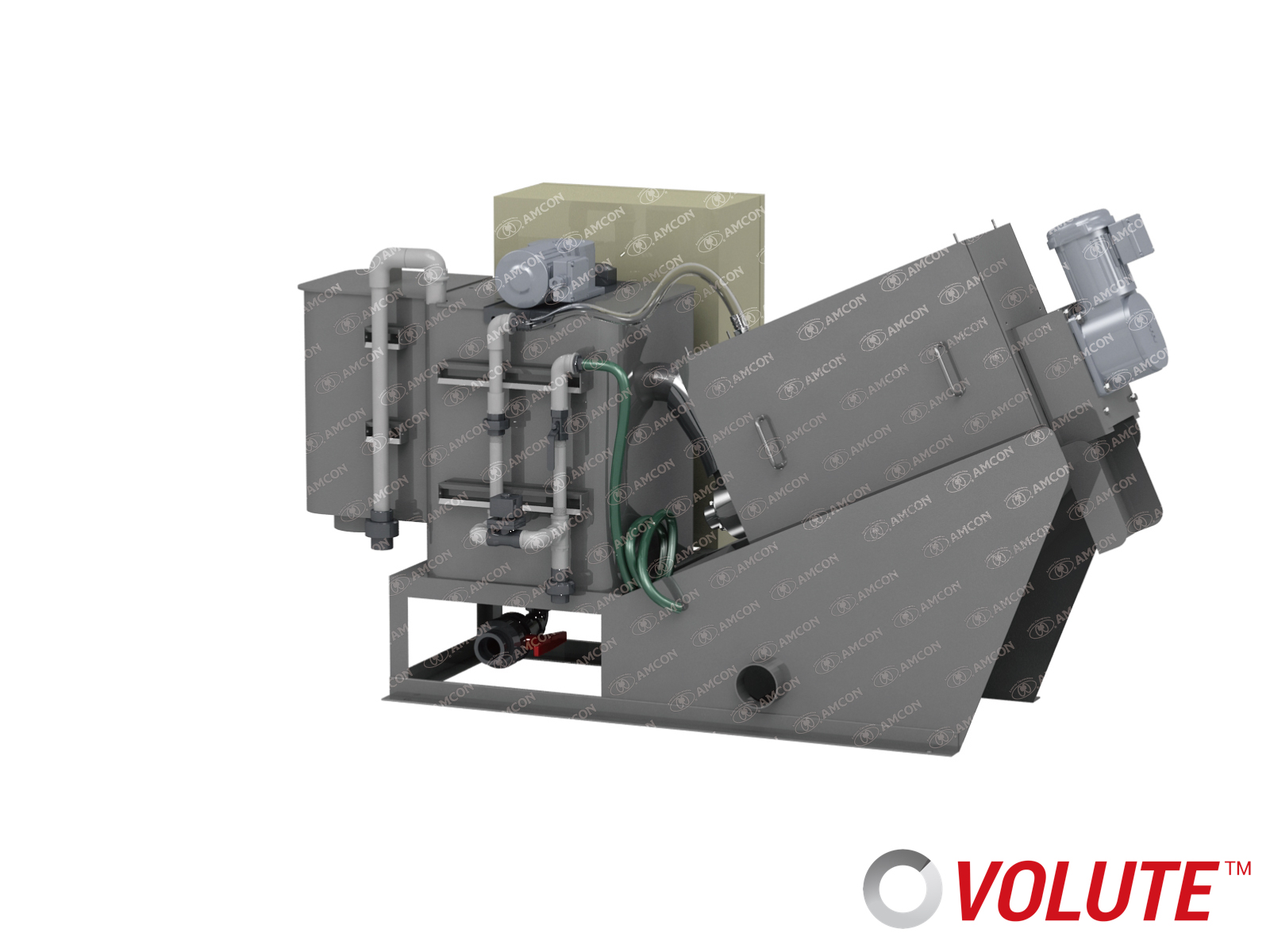

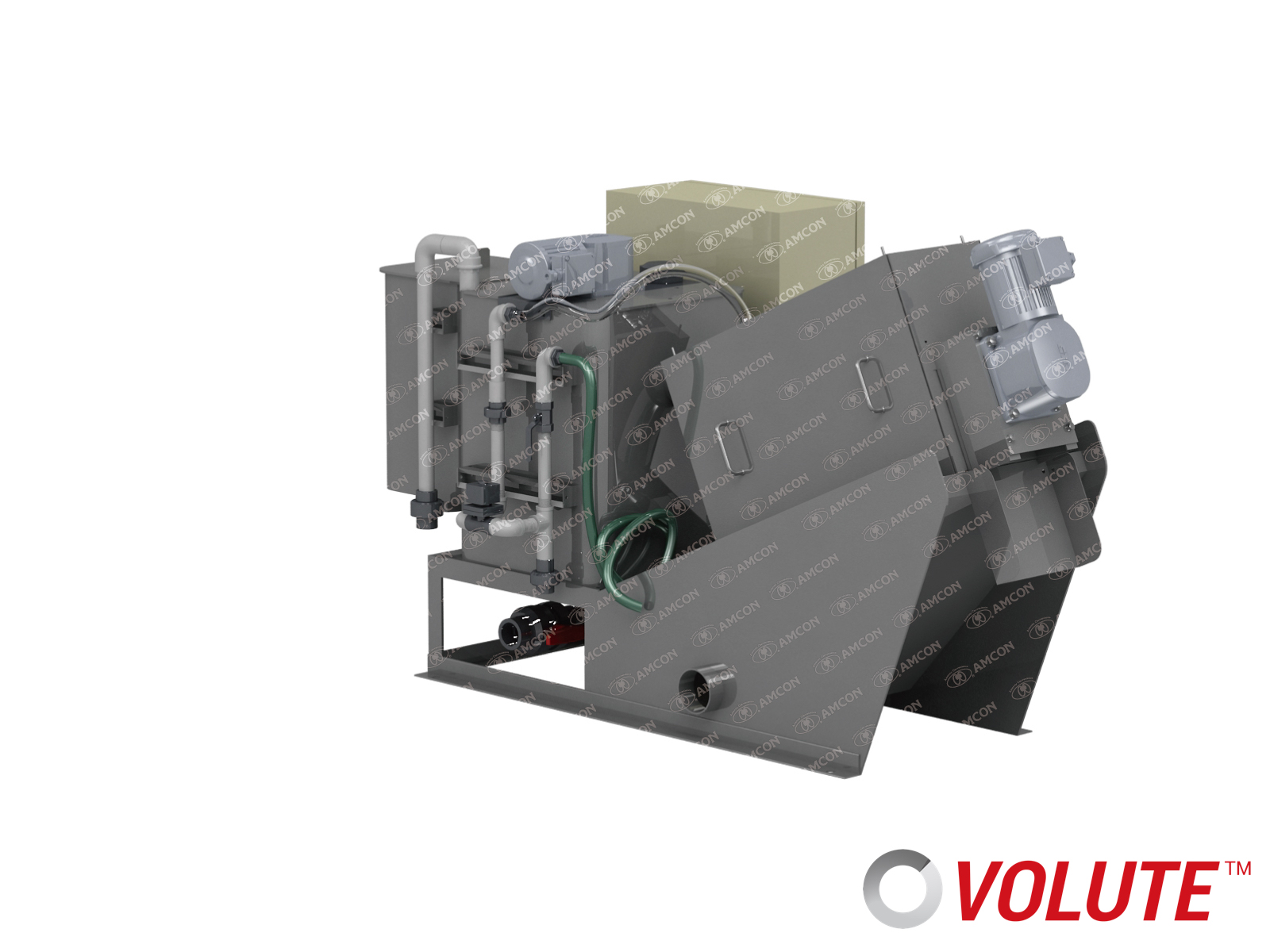

Small footprint

Small footprint -

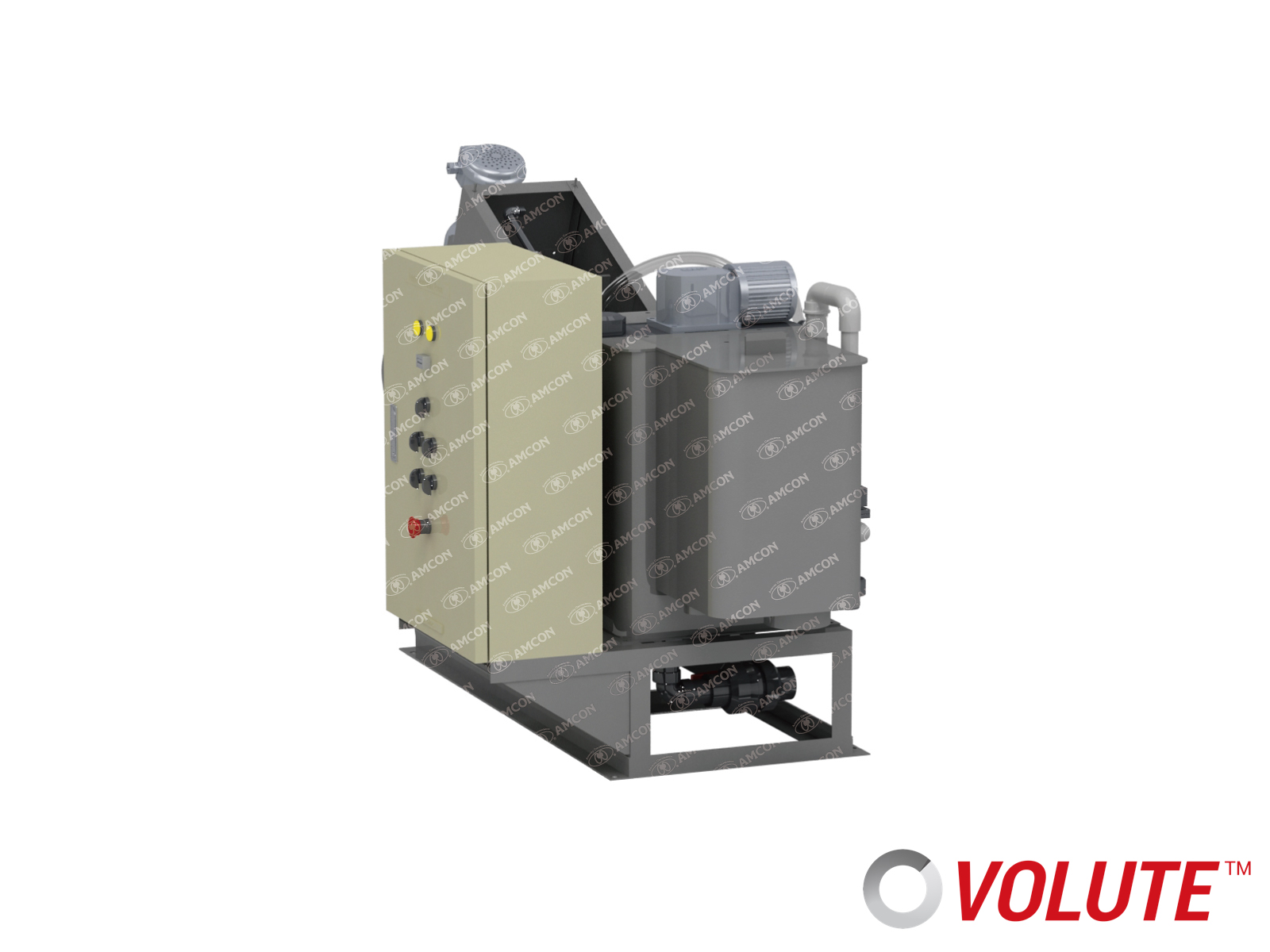

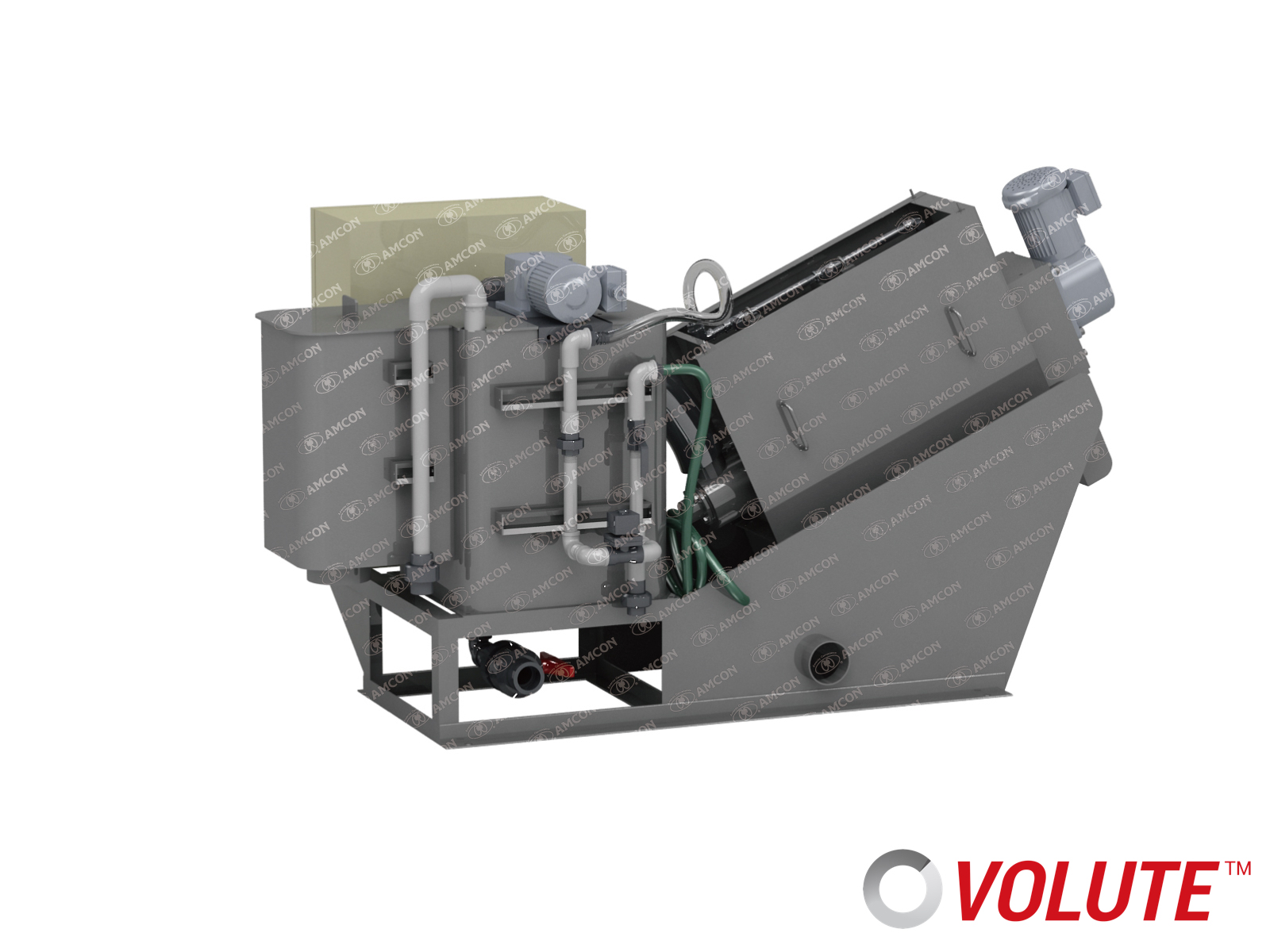

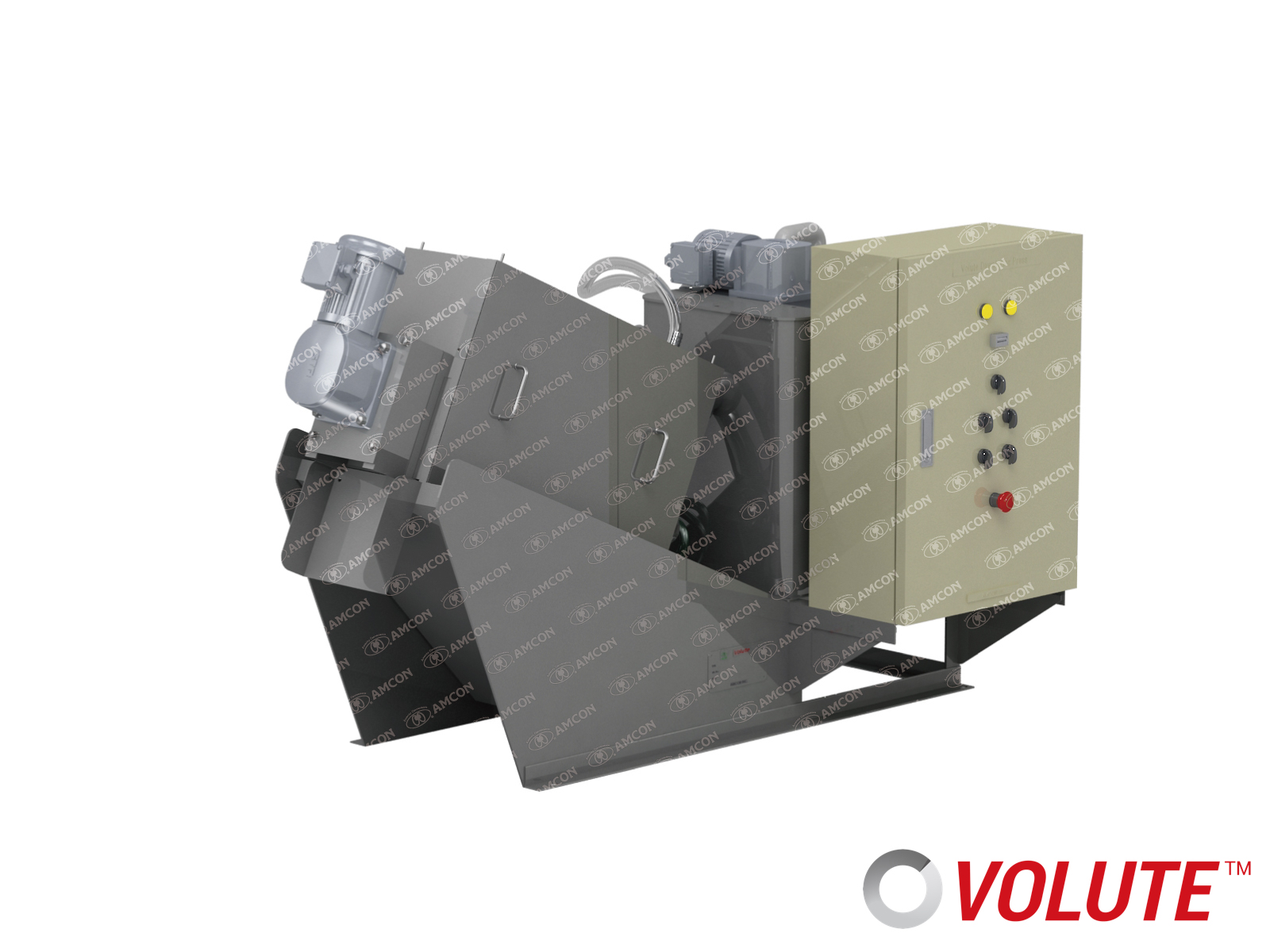

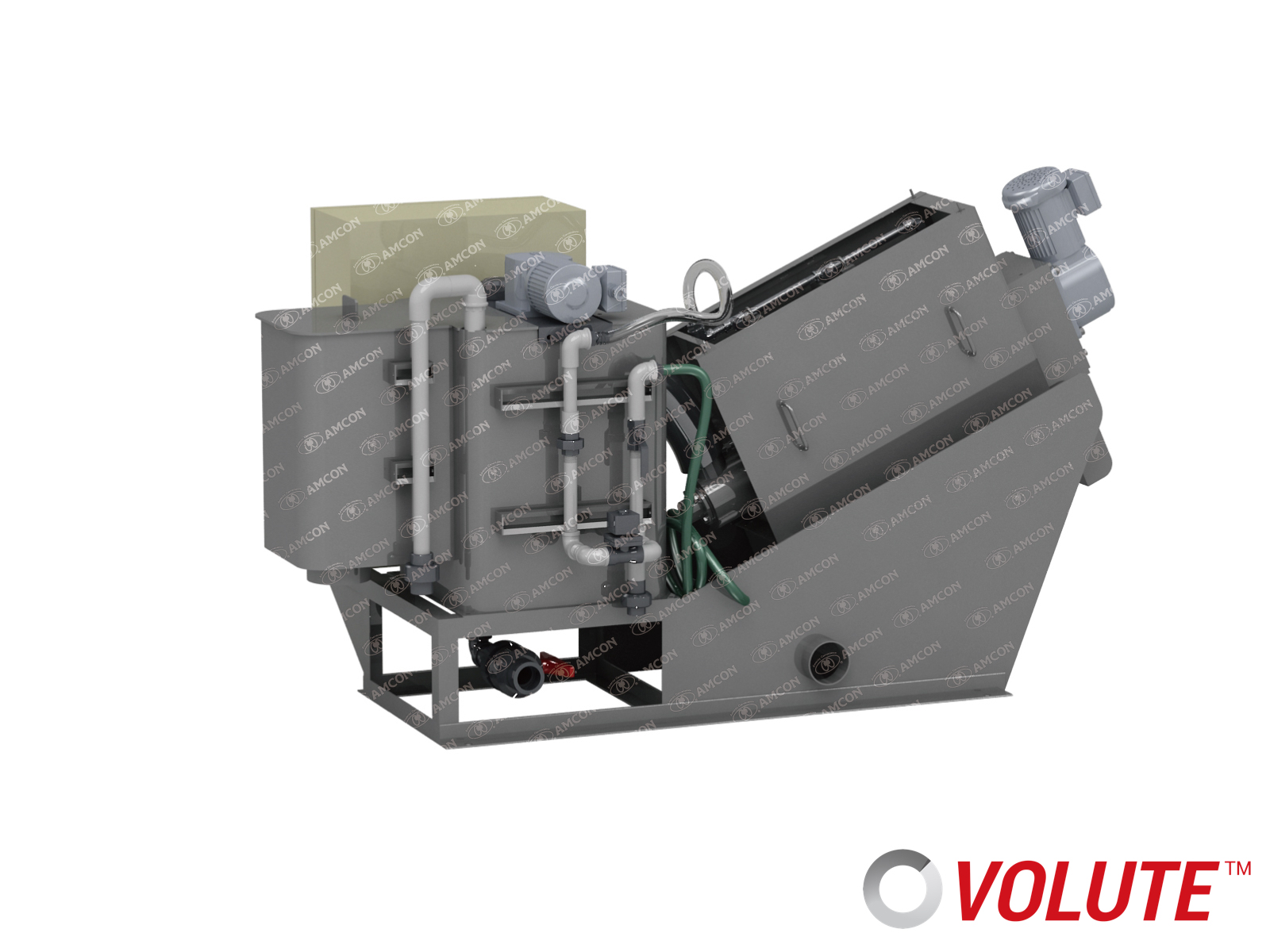

Excellent expandability

Excellent expandability

Additional cylinder unit can be added even after delivery

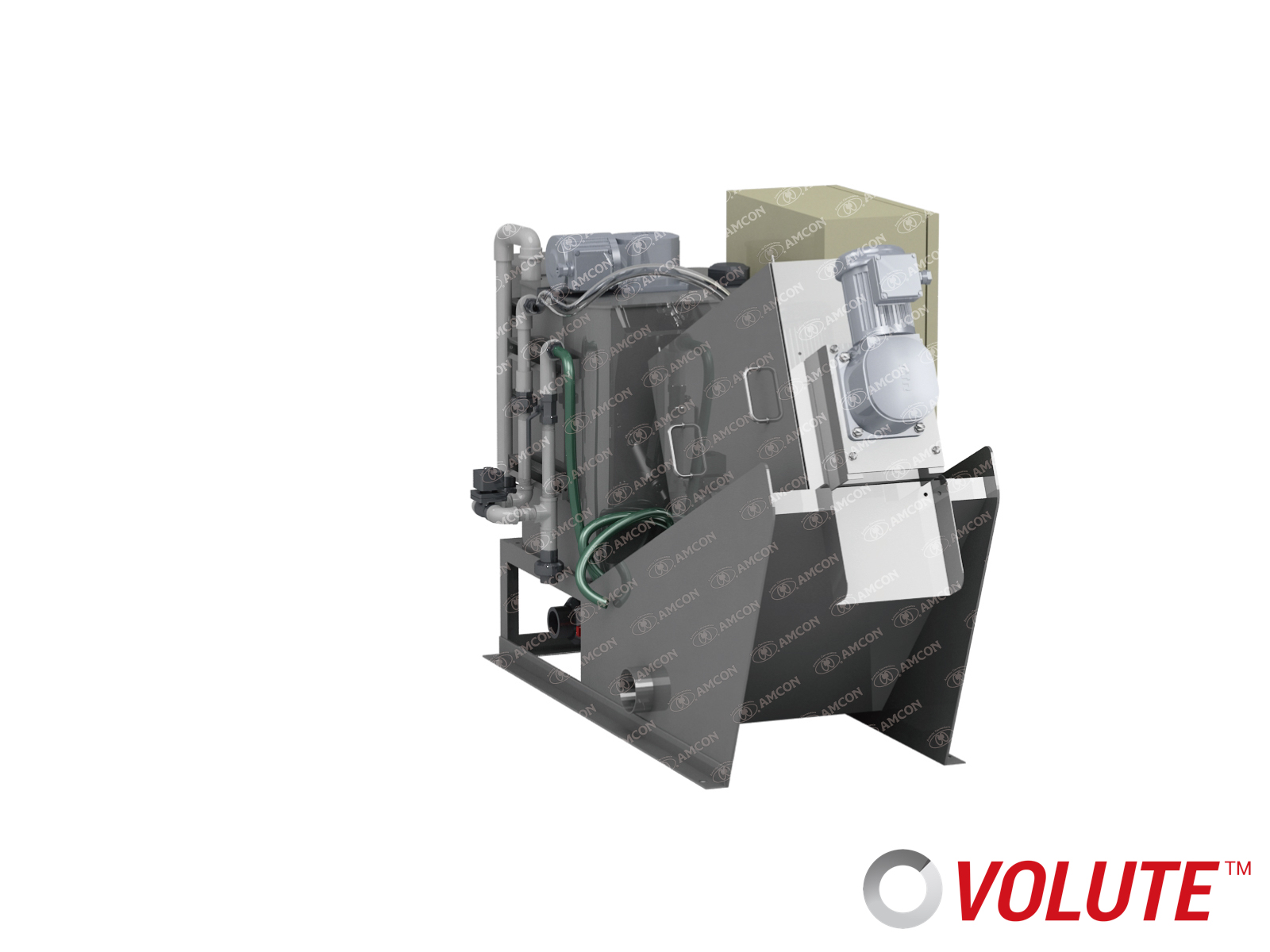

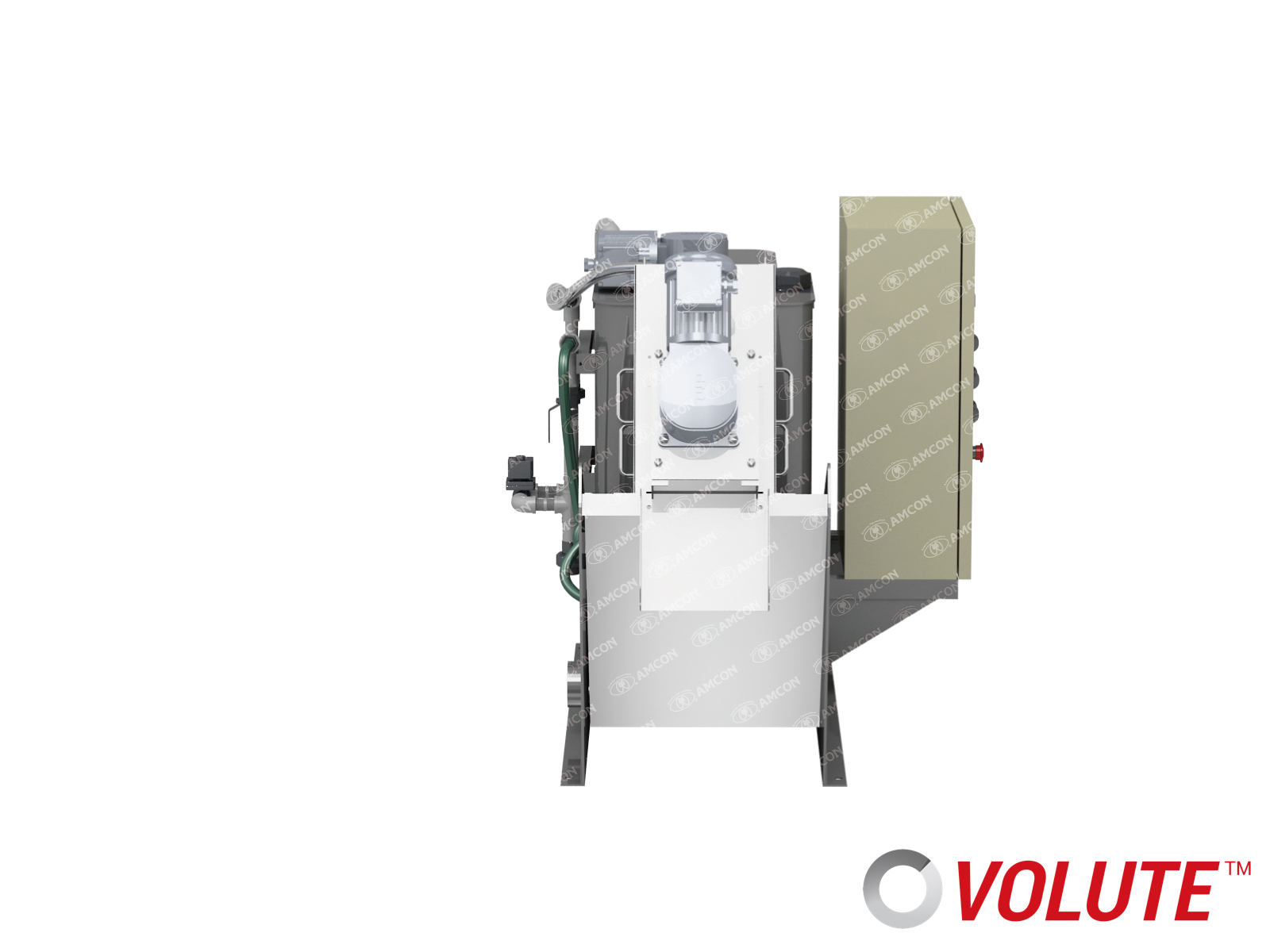

No clogging even with oily sludge

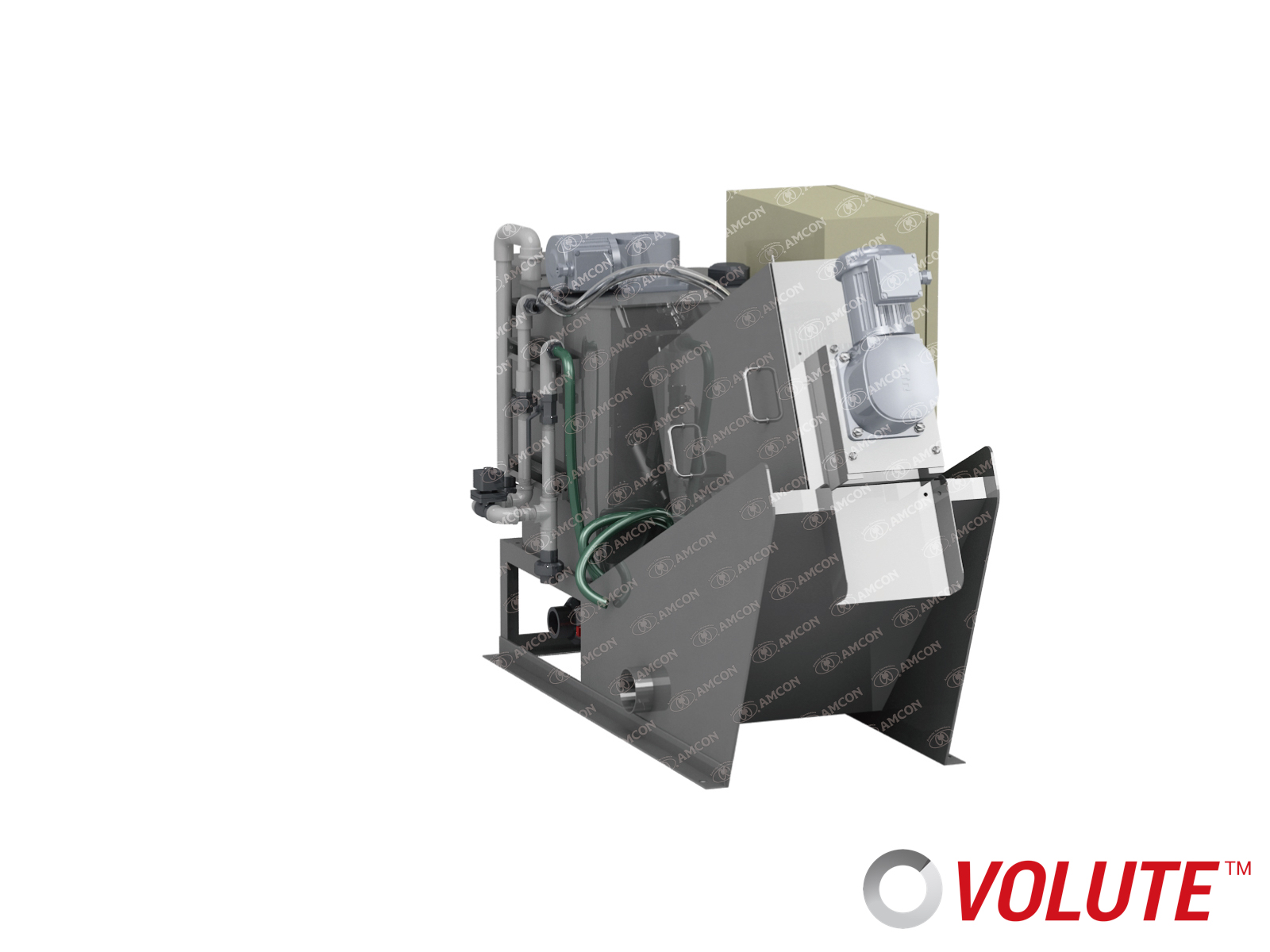

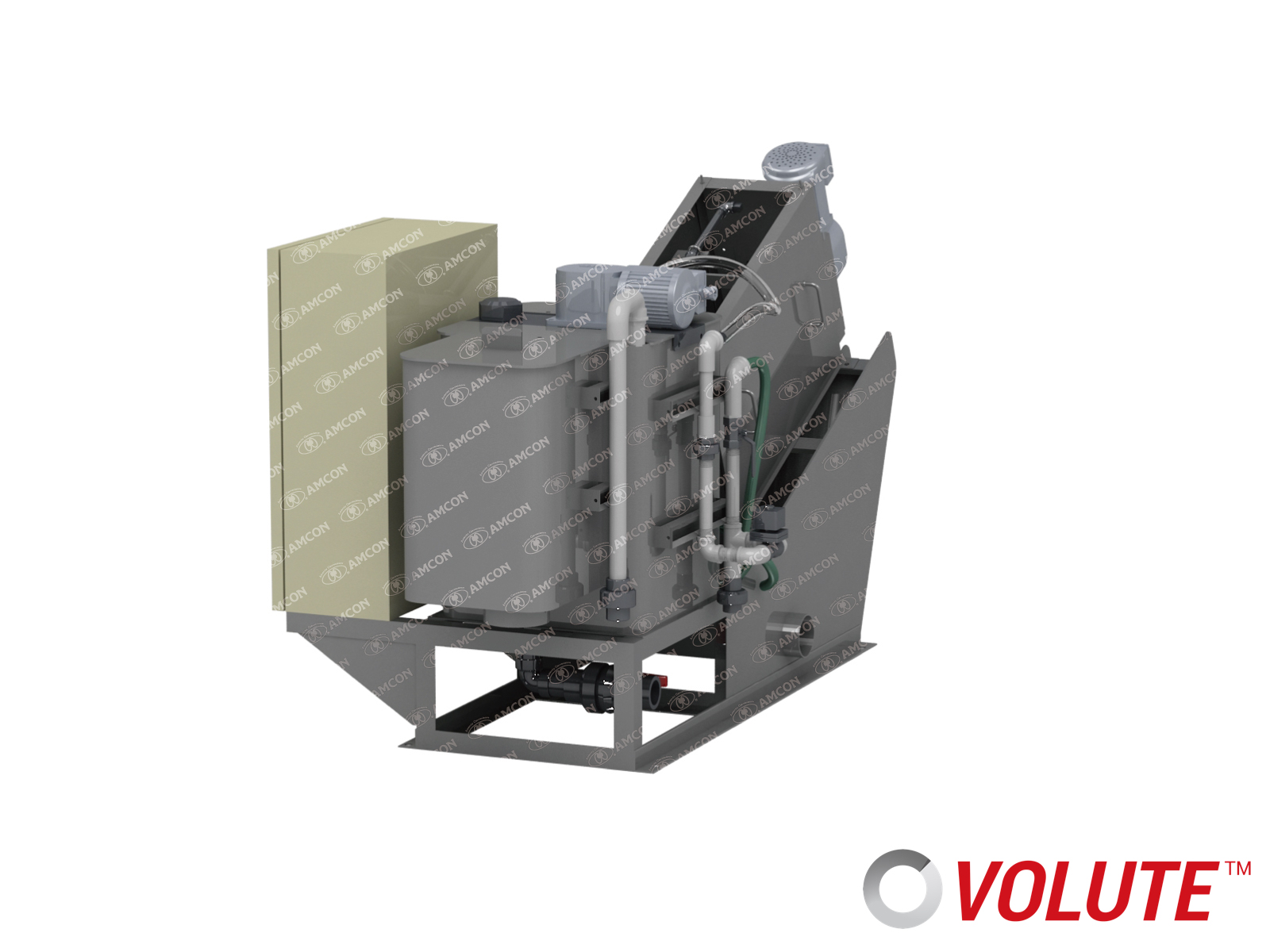

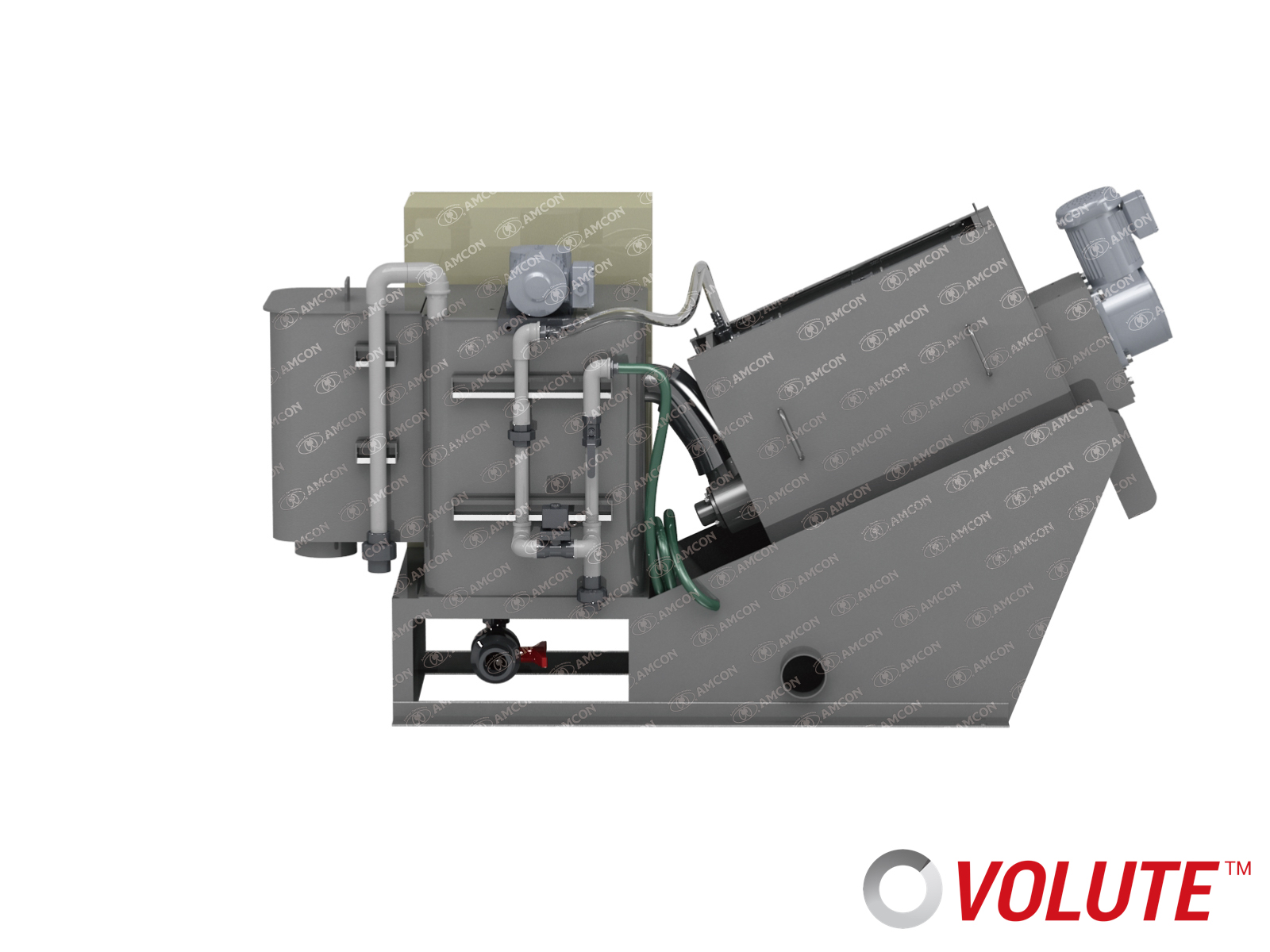

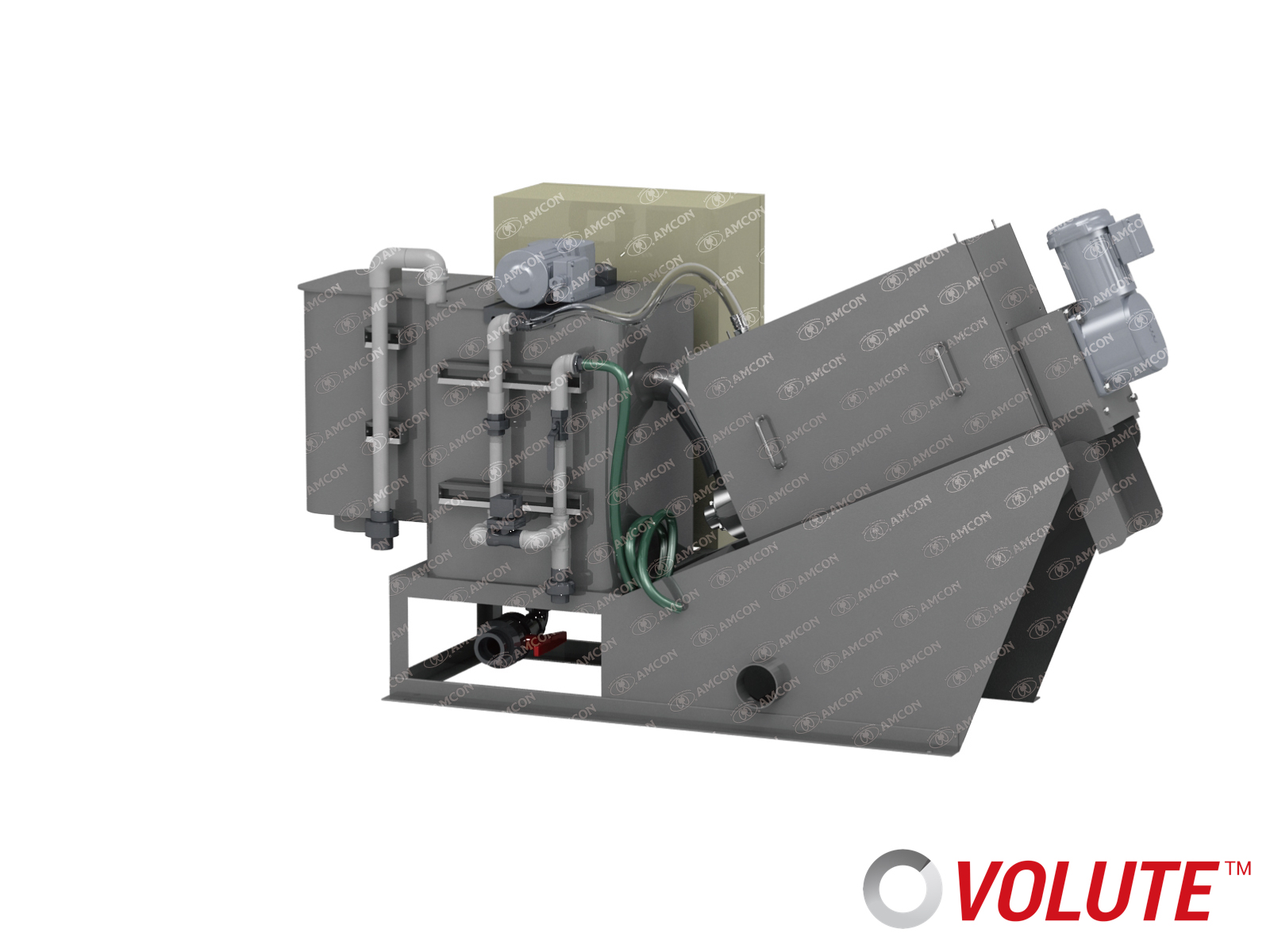

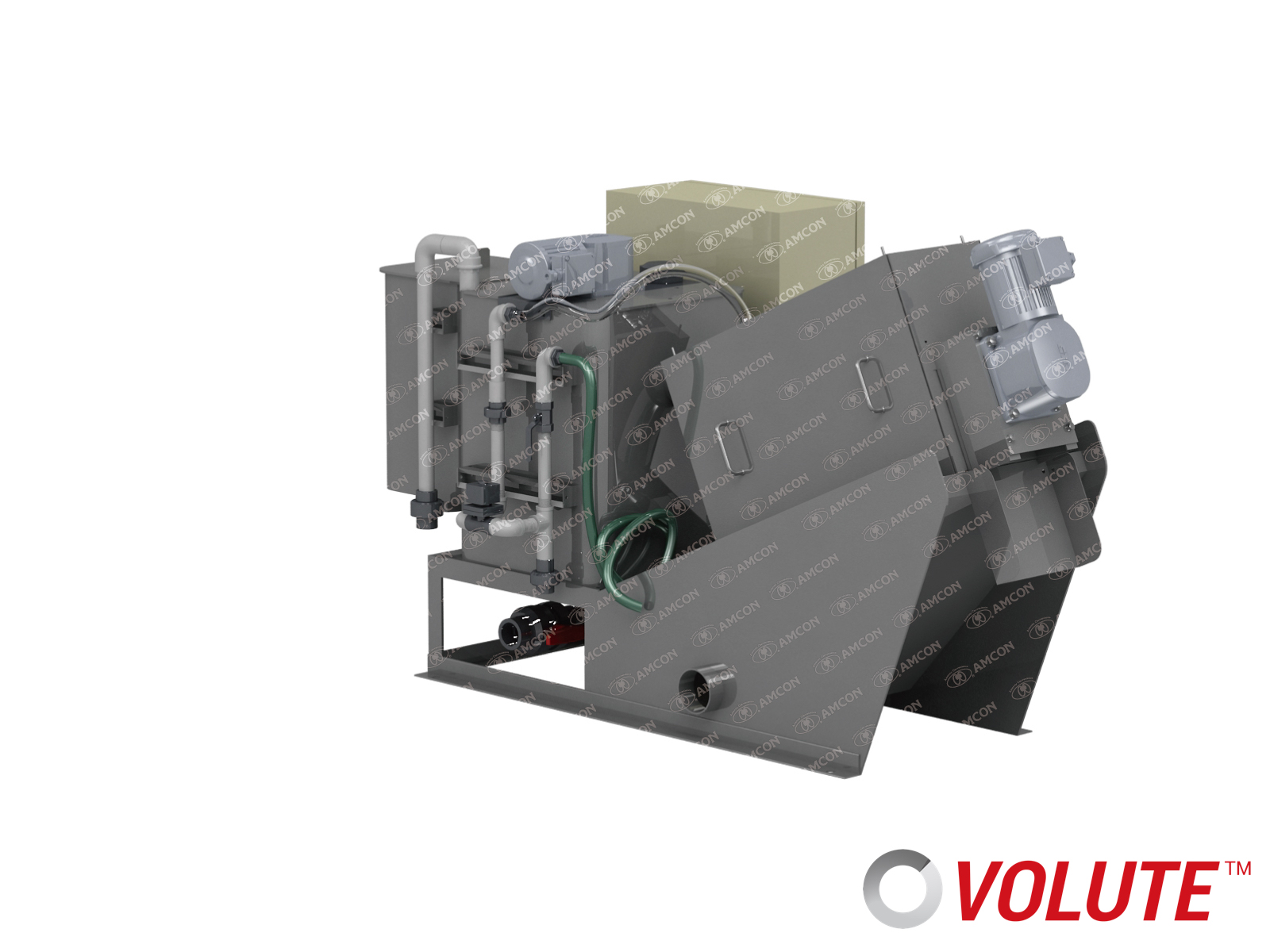

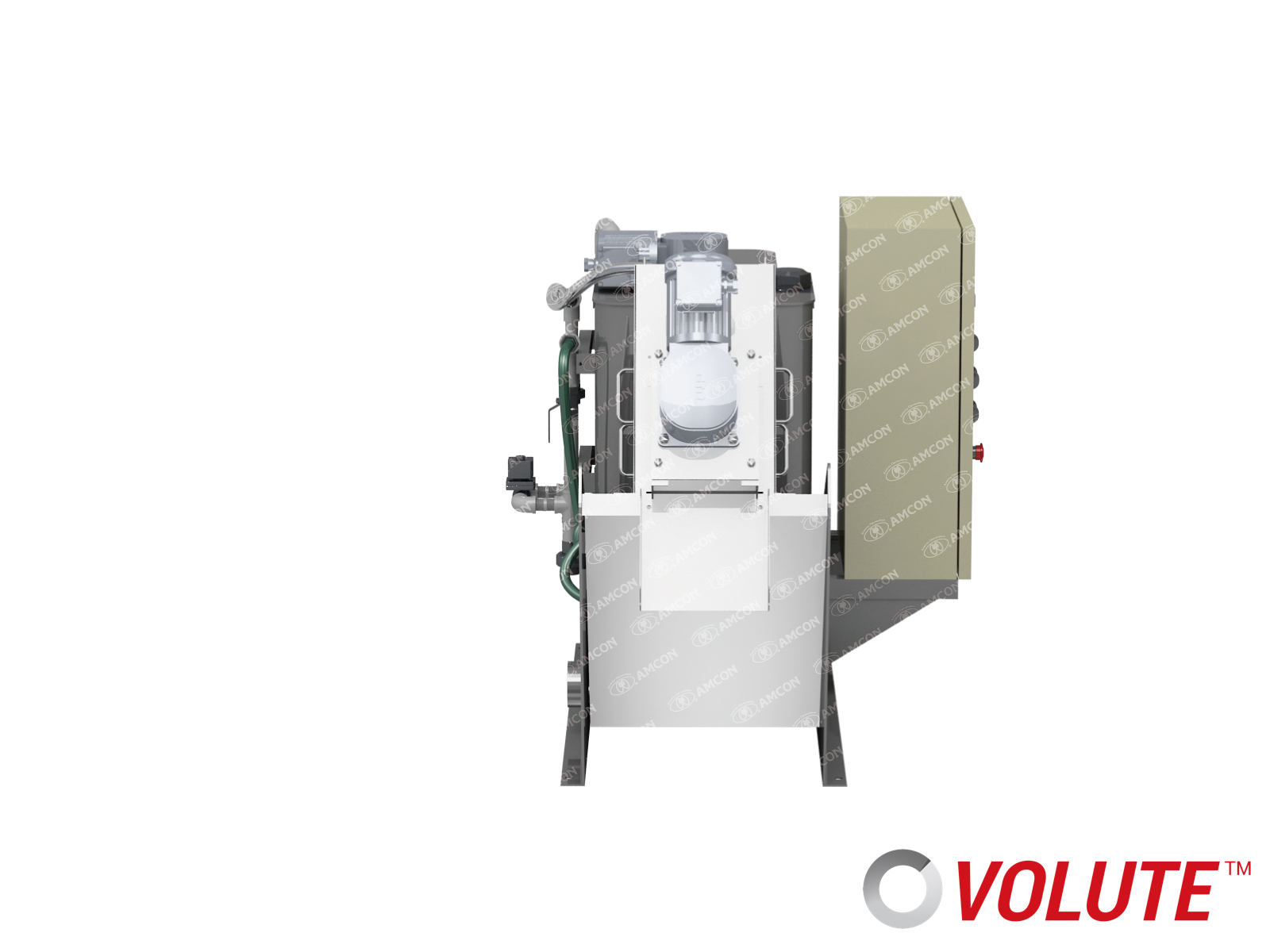

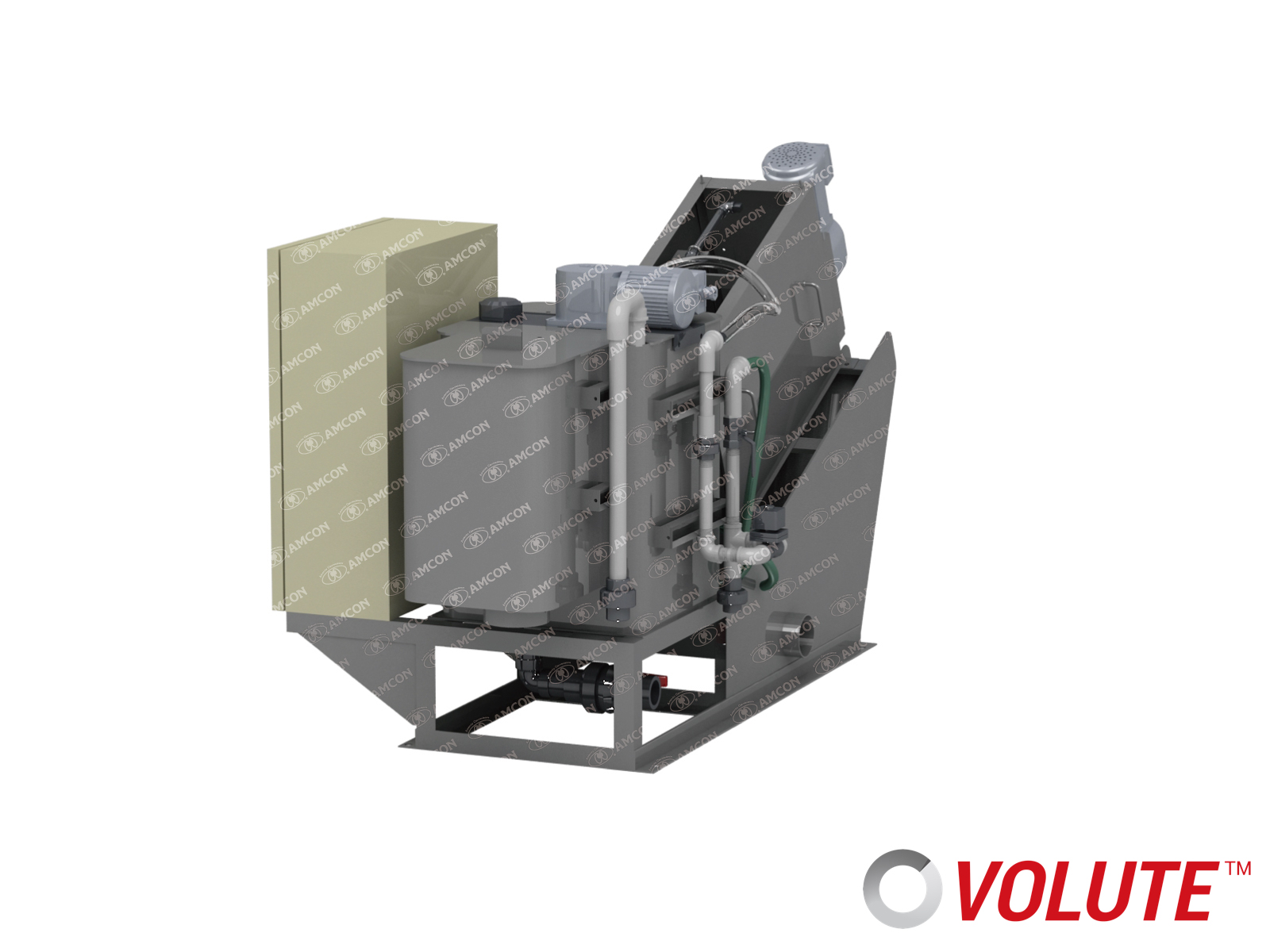

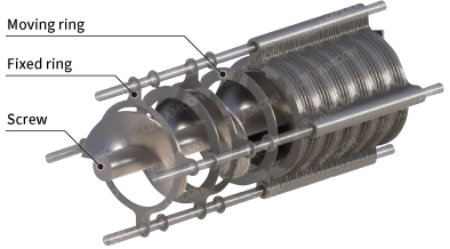

The machine has a filter element that consists of alternating layers of rings fixed at four locations (fixed rings) and vertically movable rings (moving rings) maintaining a gap between them, and a single screw that is threaded through the filter element to transfer and compact the sludge.

A clog-free self-cleaning mechanism is achieved since the screw rotates at a constant speed in contact with the floating ring, driving the floating ring to clean the filter element gap.

The machine delivers stable dewatering performance even with oily sludge.

The amount of cleaning water for preventing clogging is very small compared to other types of dewatering machines.

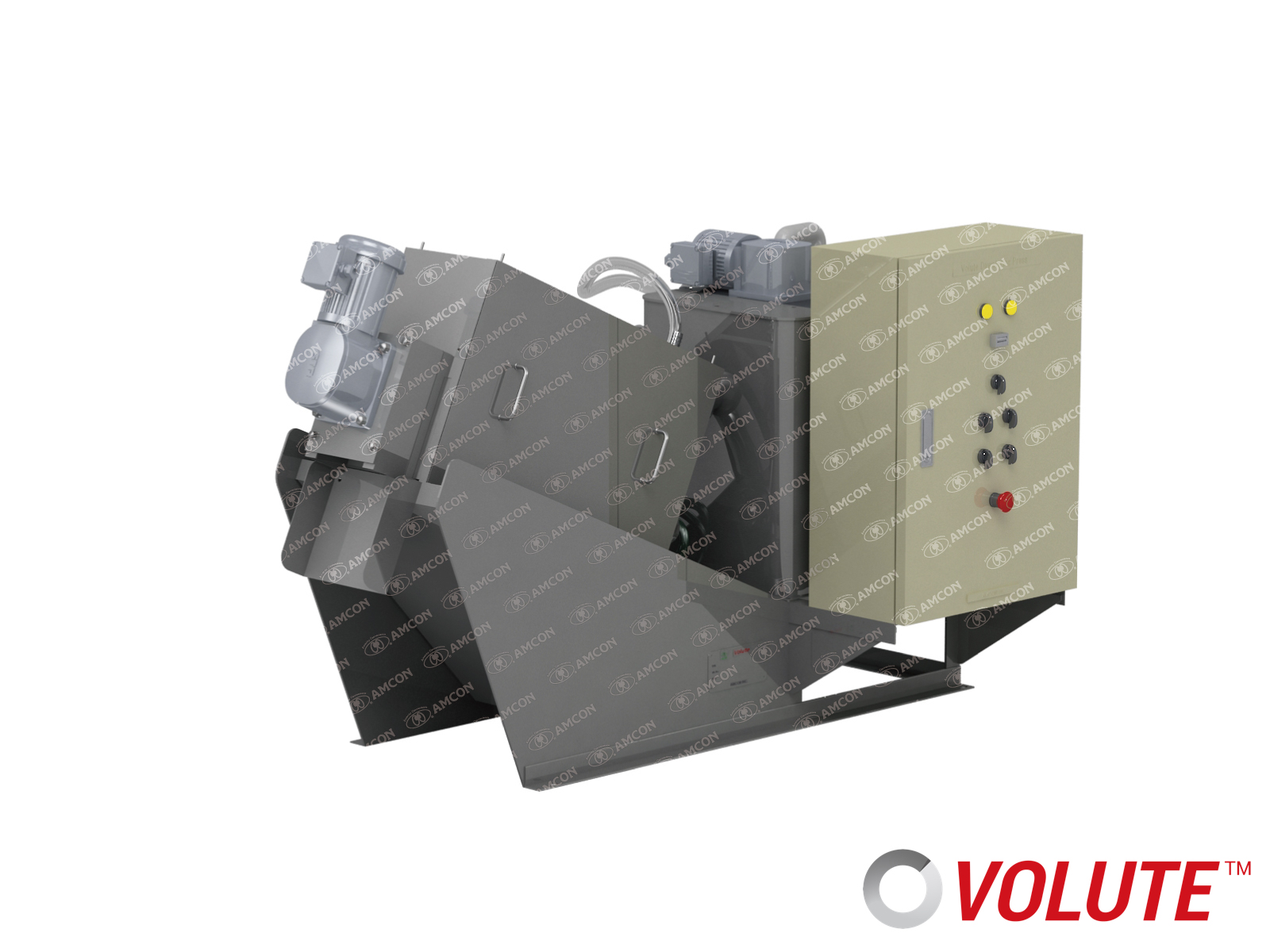

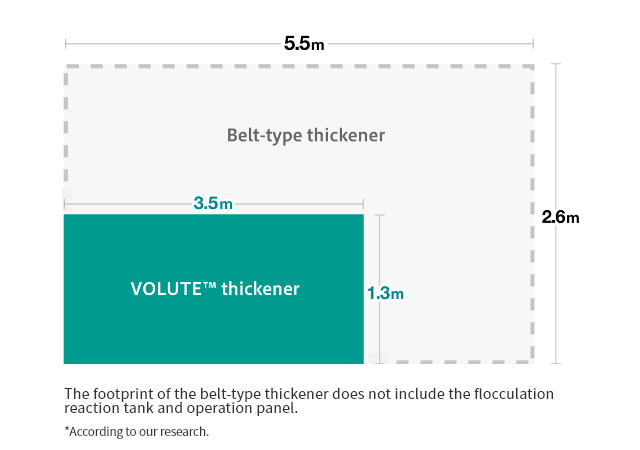

Small footprint

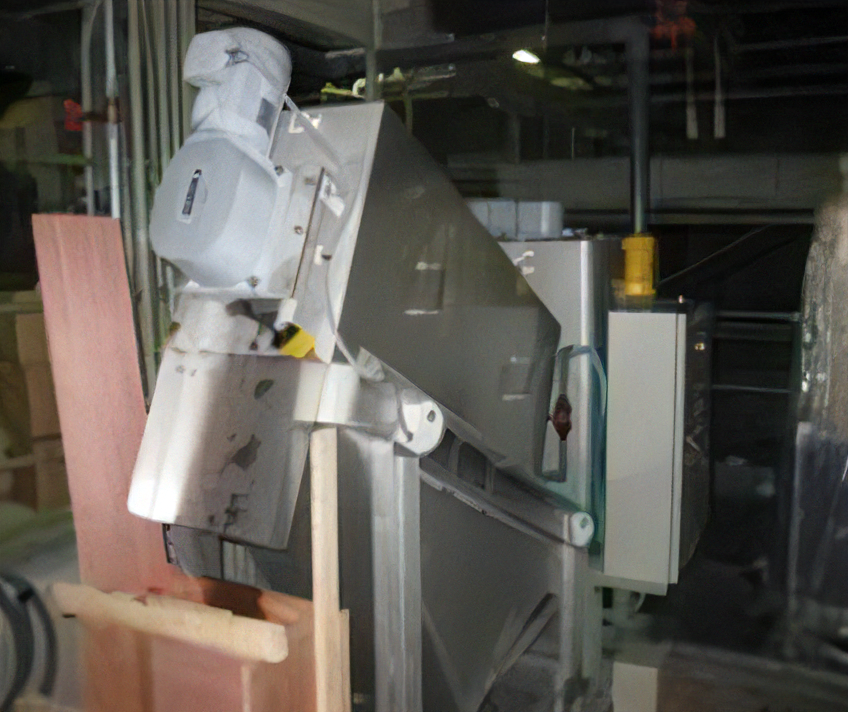

This model can also be installed in places where other types of thickeners would be difficult to install, such as in low-ceiling buildings or where the footprint is limited.

This model does not require any cost on building extensions to secure an footprint, so it is also ideal when considering the replacement of an existing thickener.

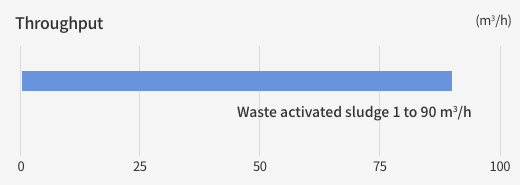

When comparing the VOLUTE™ to a belt-type thickener, both having a throughput of 30 m3/h, the footprint is about 1/3.

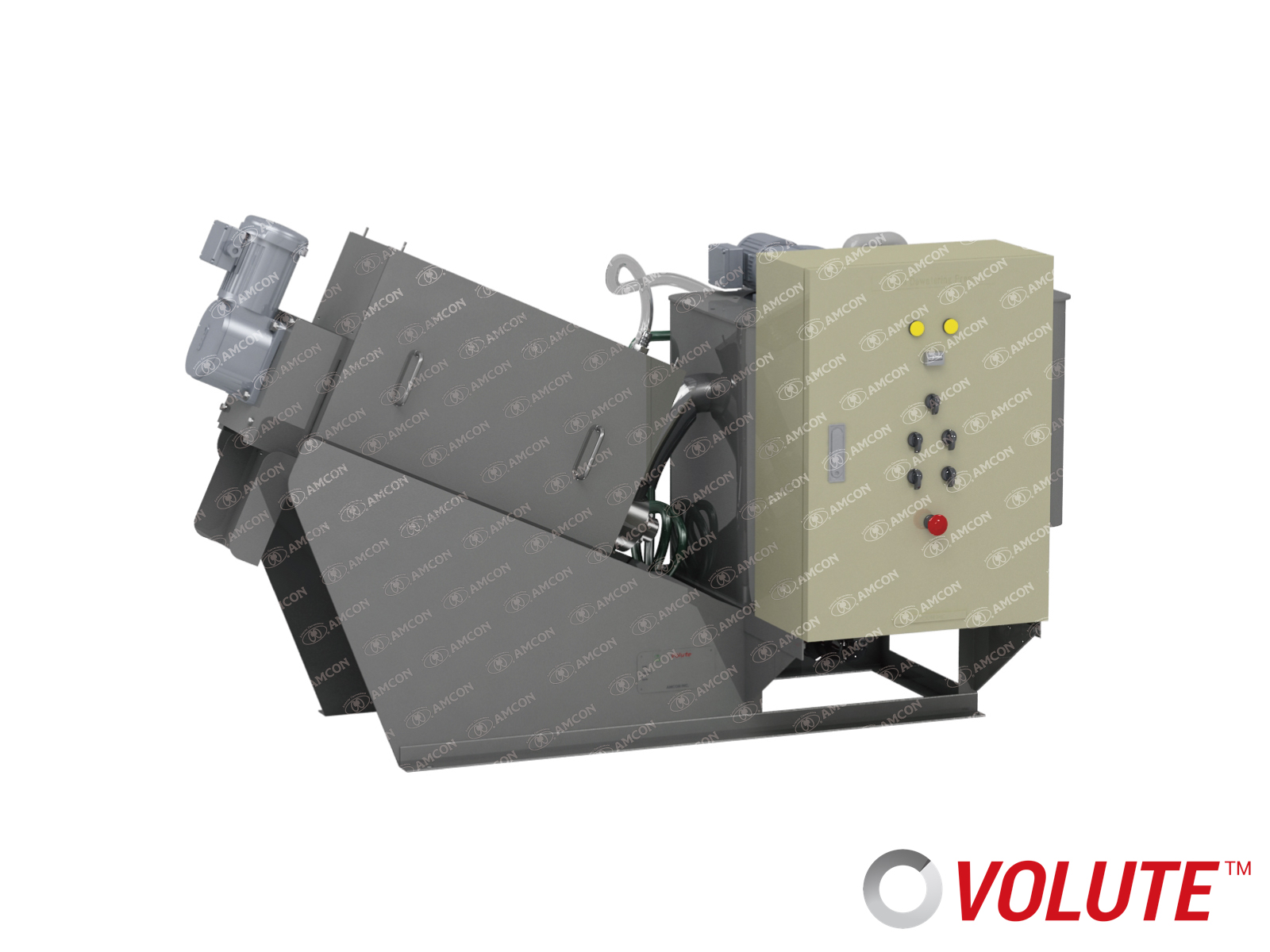

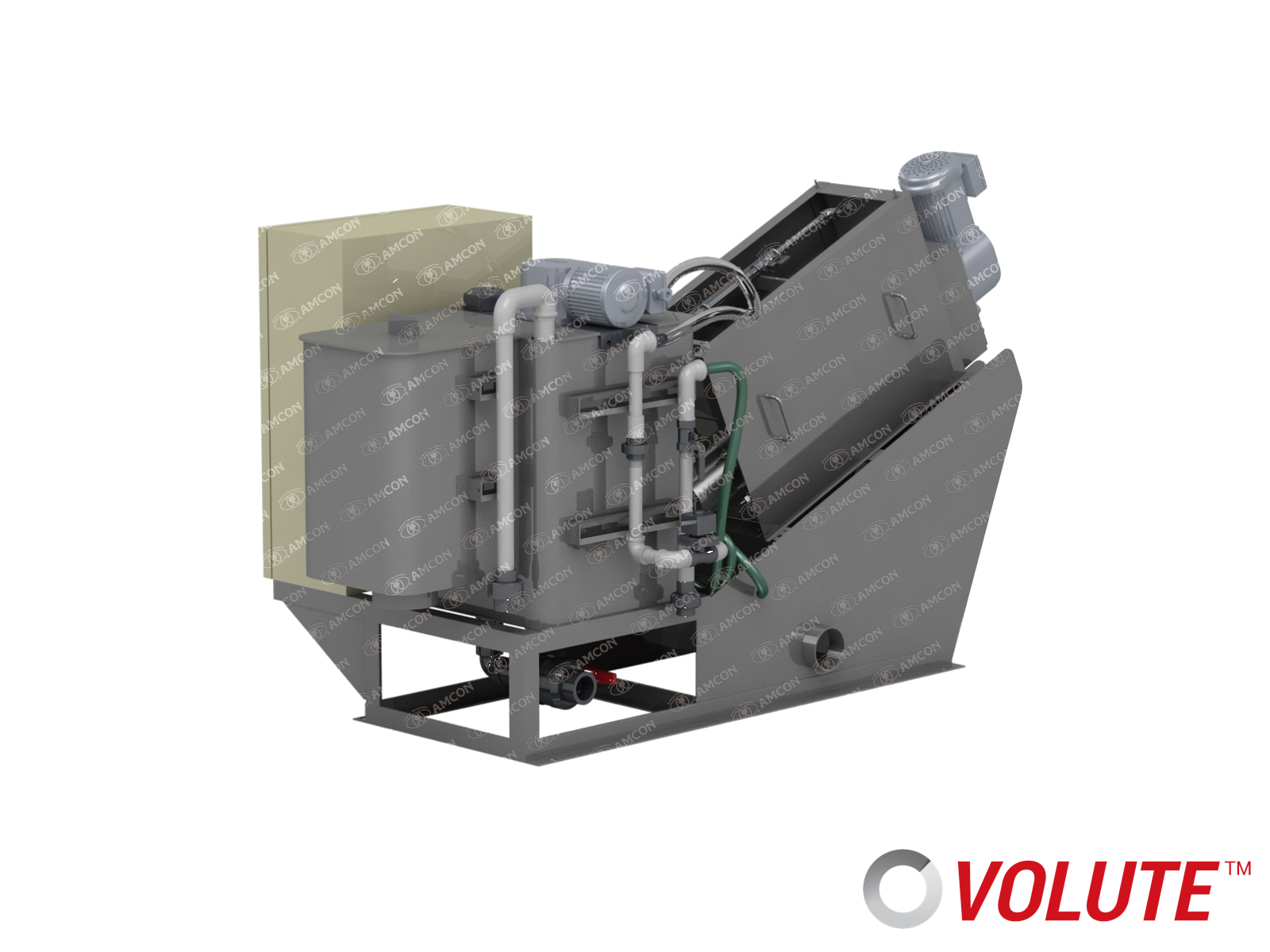

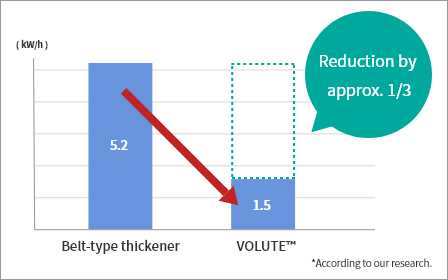

Power-saving operation

The screw in the filter element rotates at a very low speed of approximately 2 to 4 rpm and consumes very little power, resulting in a high degree of cost-effectiveness.

When comparing the VOLUTE™ to a belt-type thickener, both having a throughput of 30 m3/h, the power consumption is about 1/3.

RENTAL

Flow for Product Installation