ADVANTAGES

-

No pre-thickening required, TS: 0.2% or more

No pre-thickening required, TS: 0.2% or more -

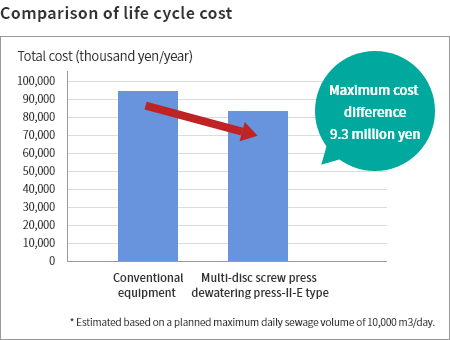

Life-cycle costs reduced by improved throughput

Life-cycle costs reduced by improved throughput -

Improved maintainability

Improved maintainability -

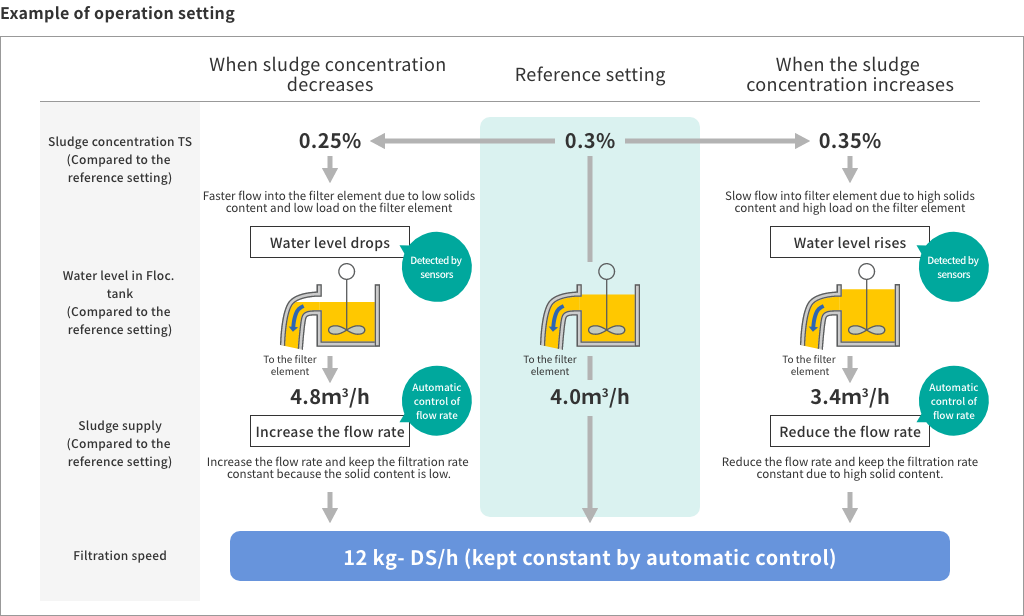

Realize stable operation with control responding to concentration fluctuations

Realize stable operation with control responding to concentration fluctuations -

Water-saving & Power-saving

Water-saving & Power-saving -

Low noise and low vibration

Low noise and low vibration -

Easy operation and easy maintenance

Easy operation and easy maintenance -

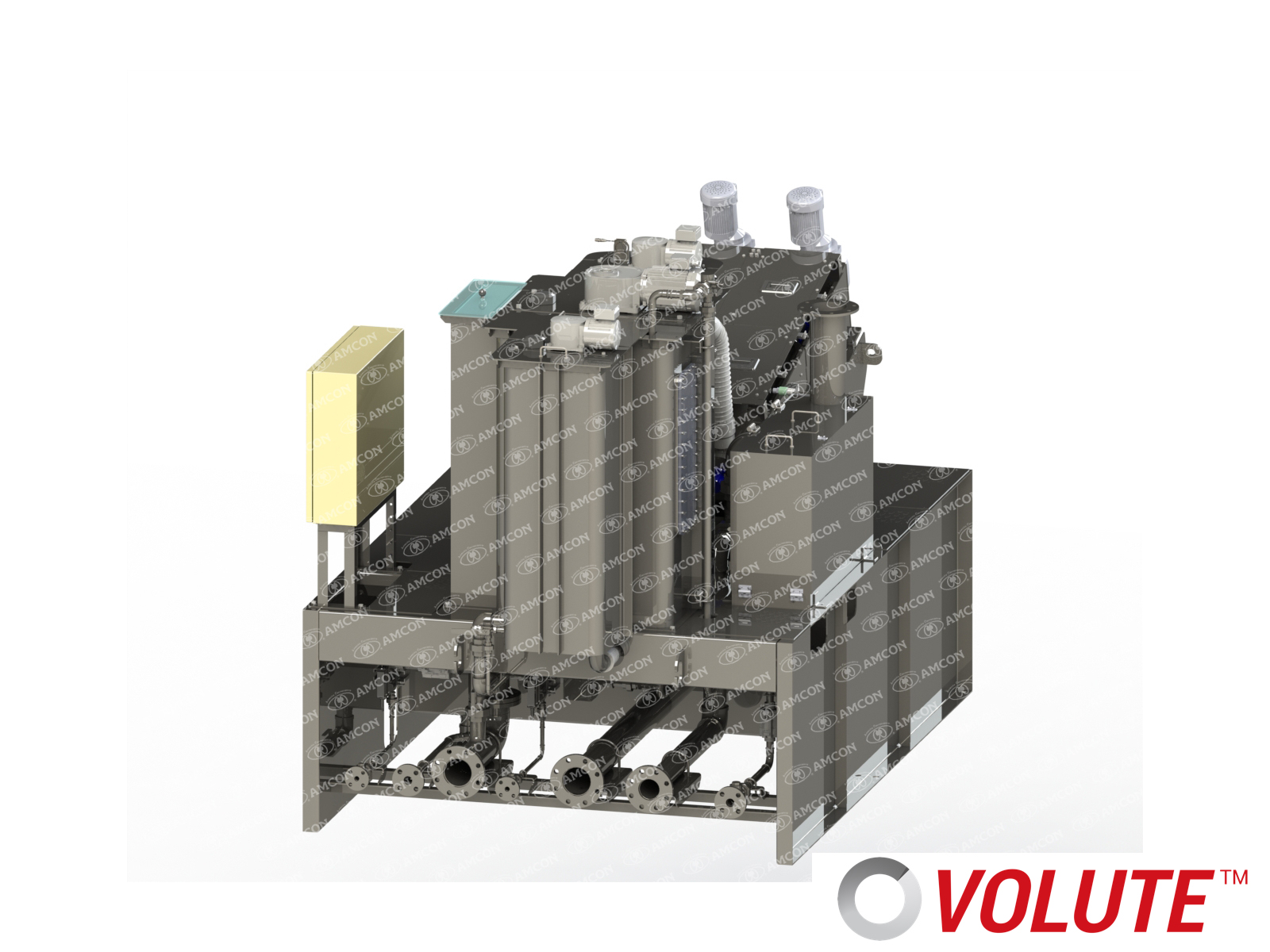

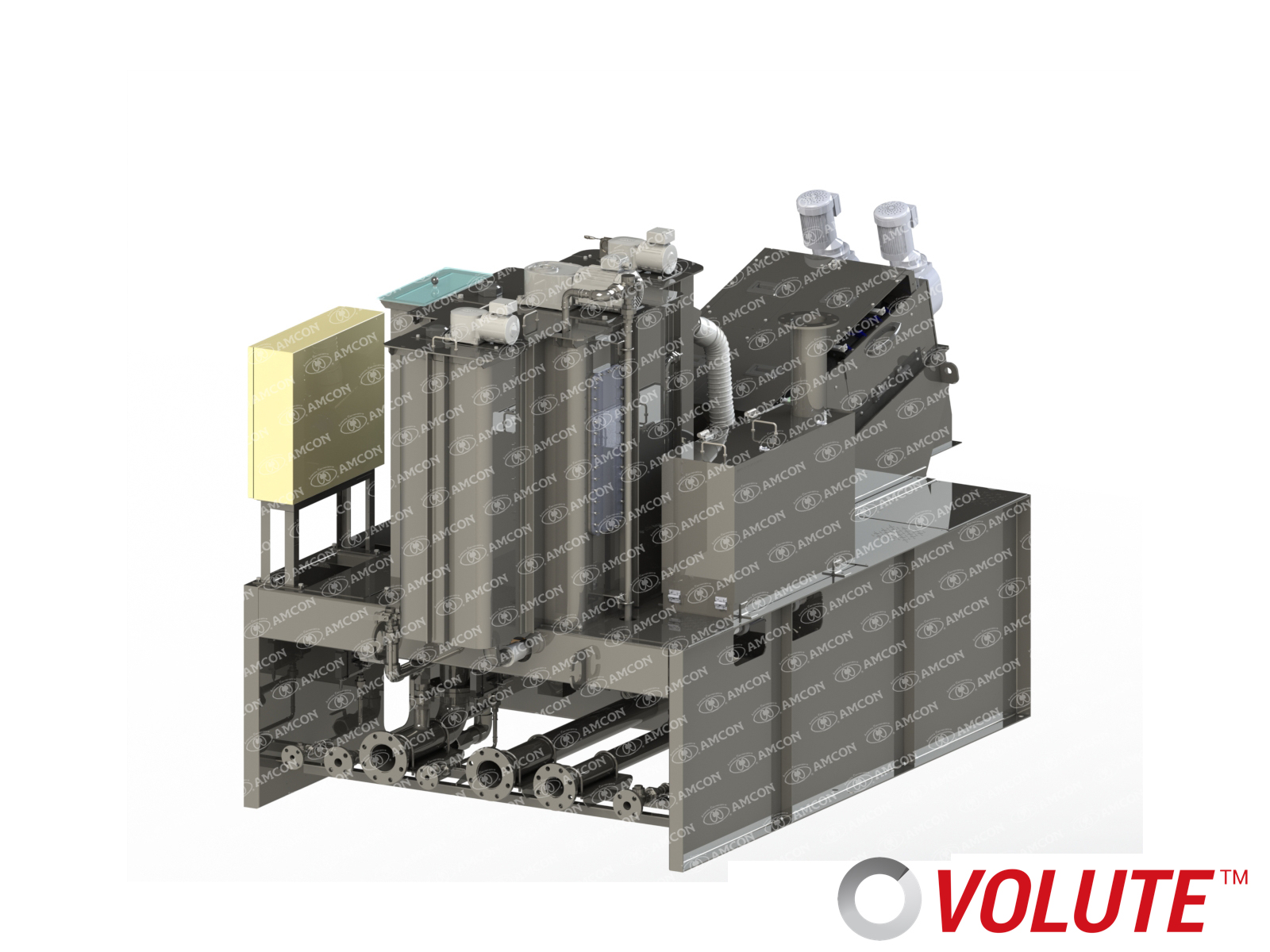

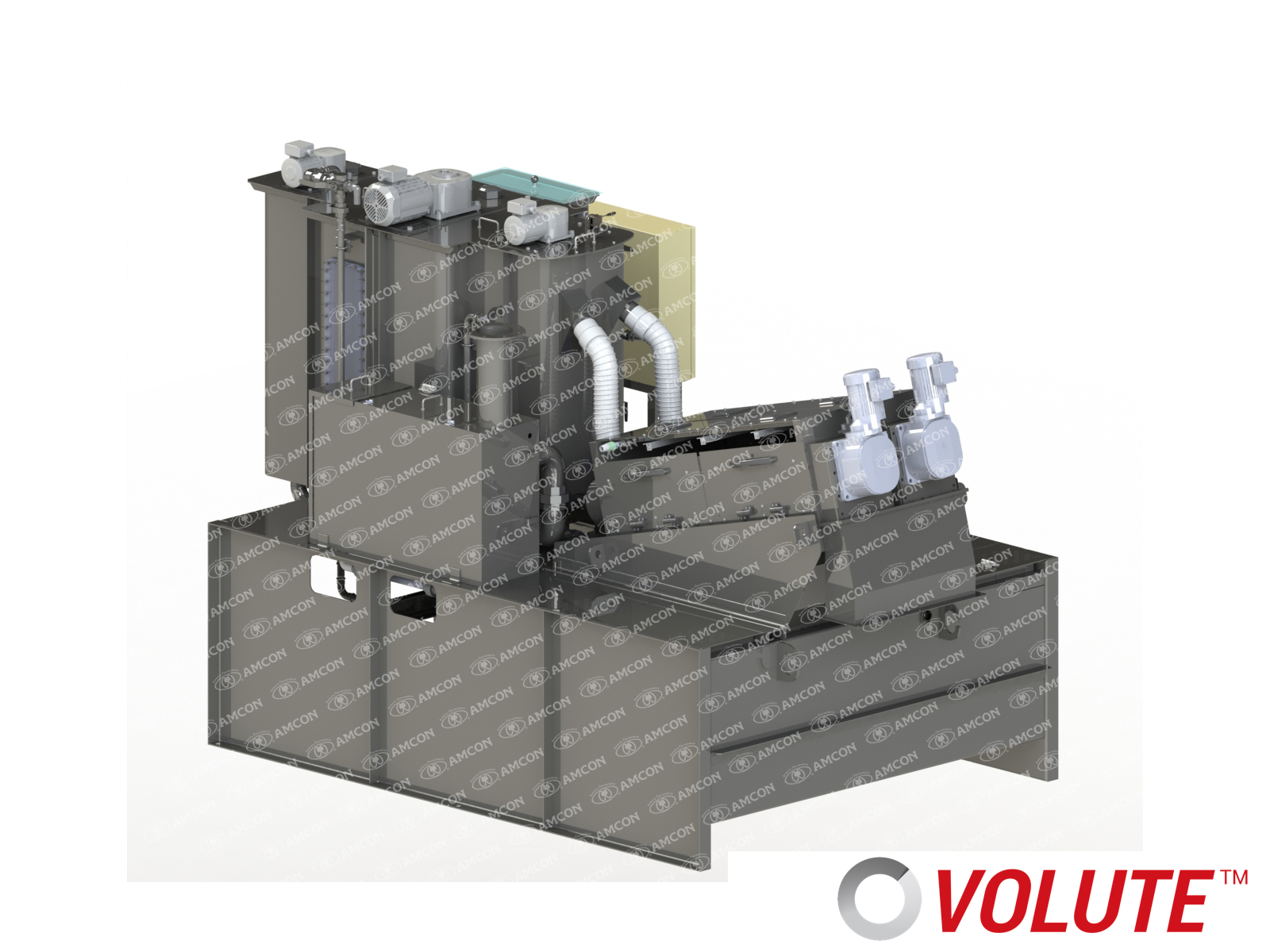

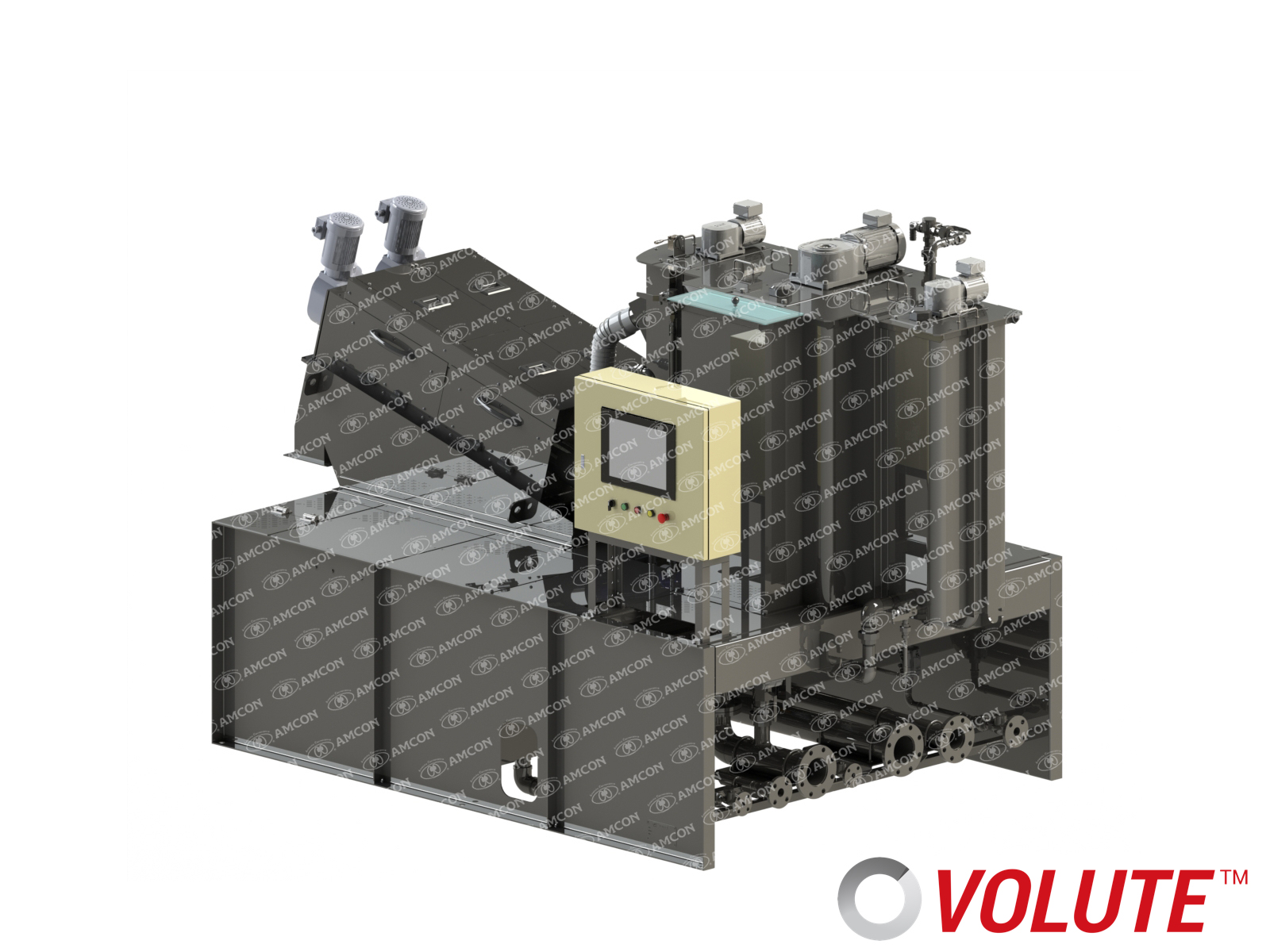

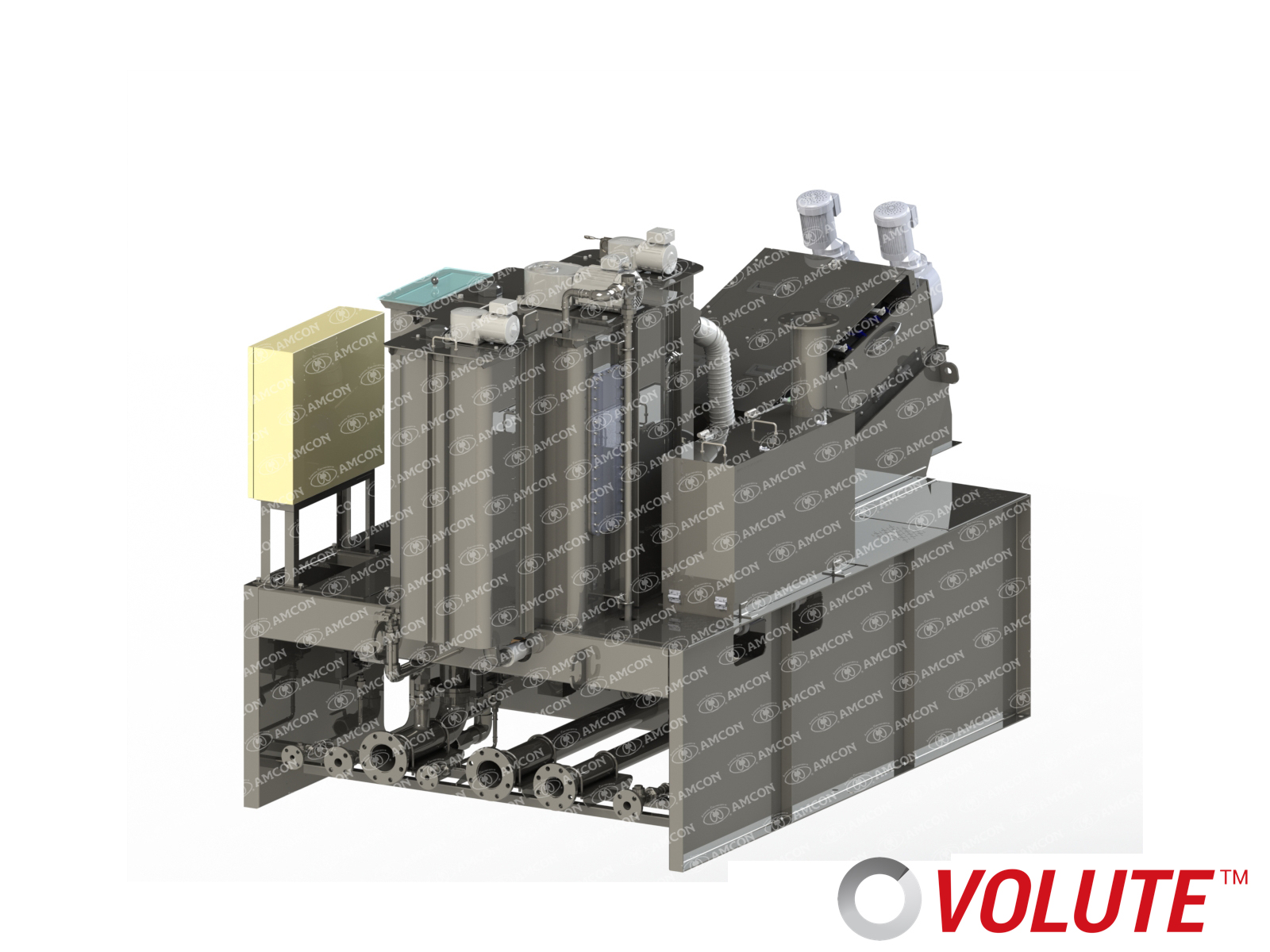

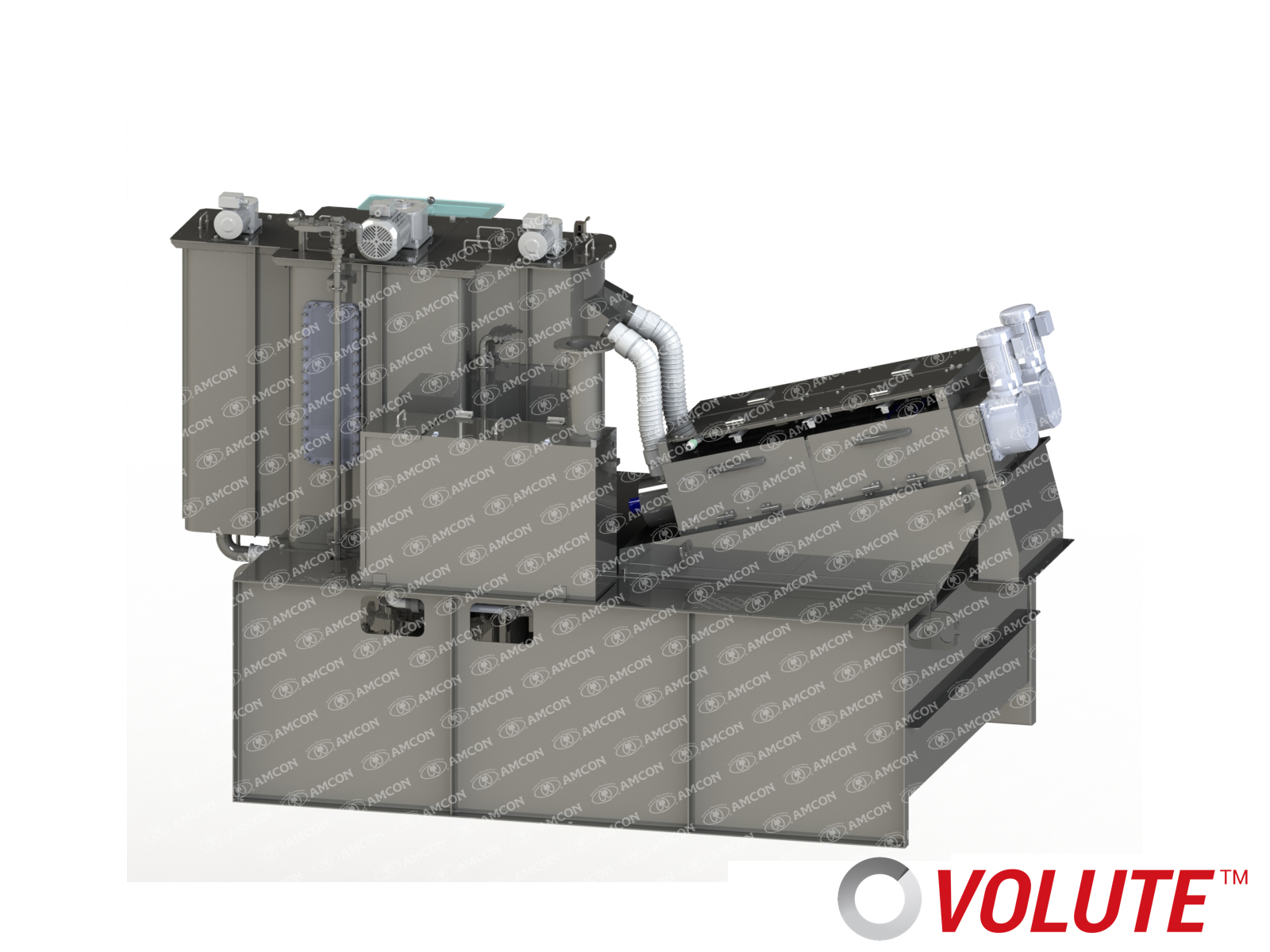

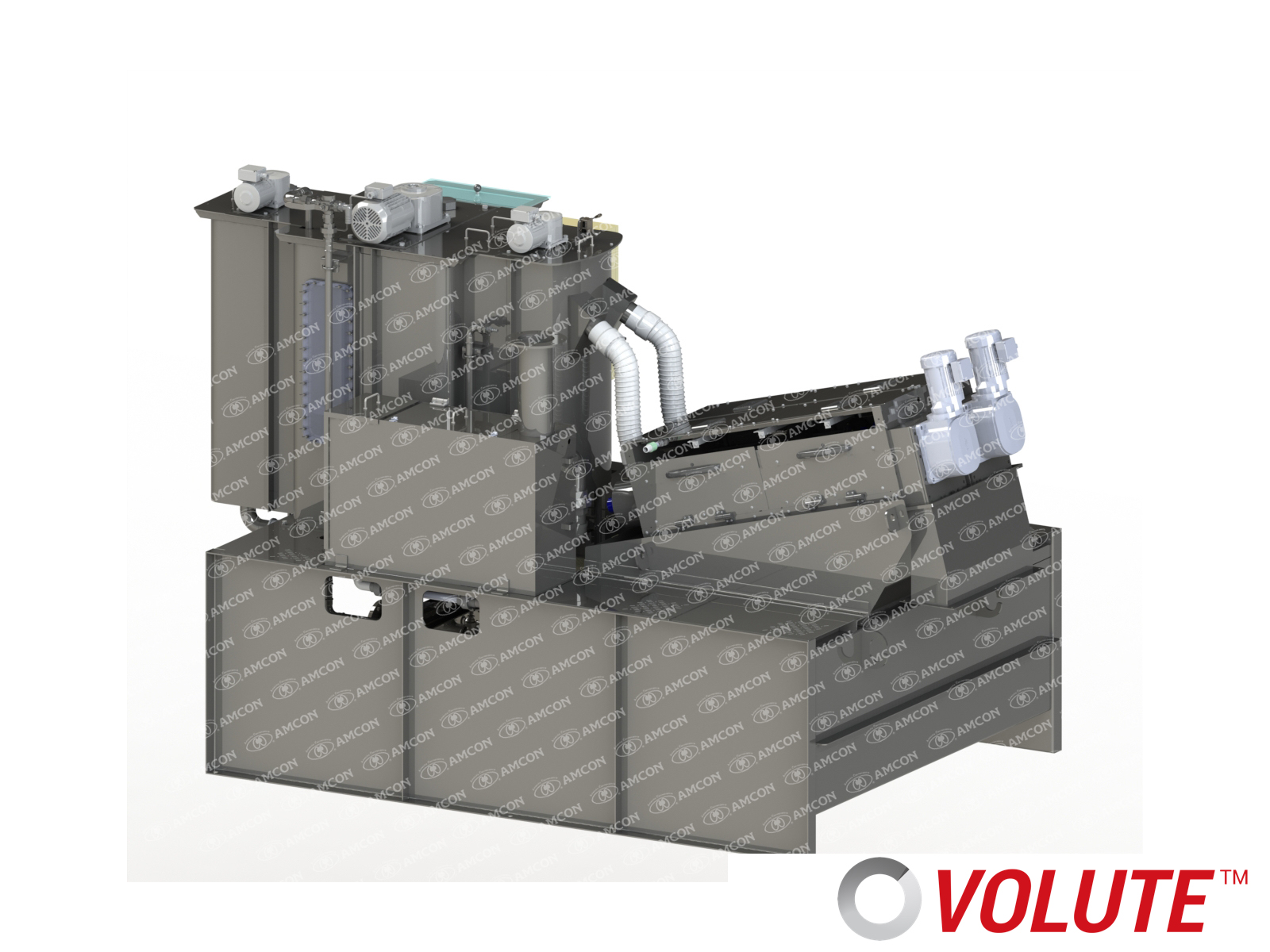

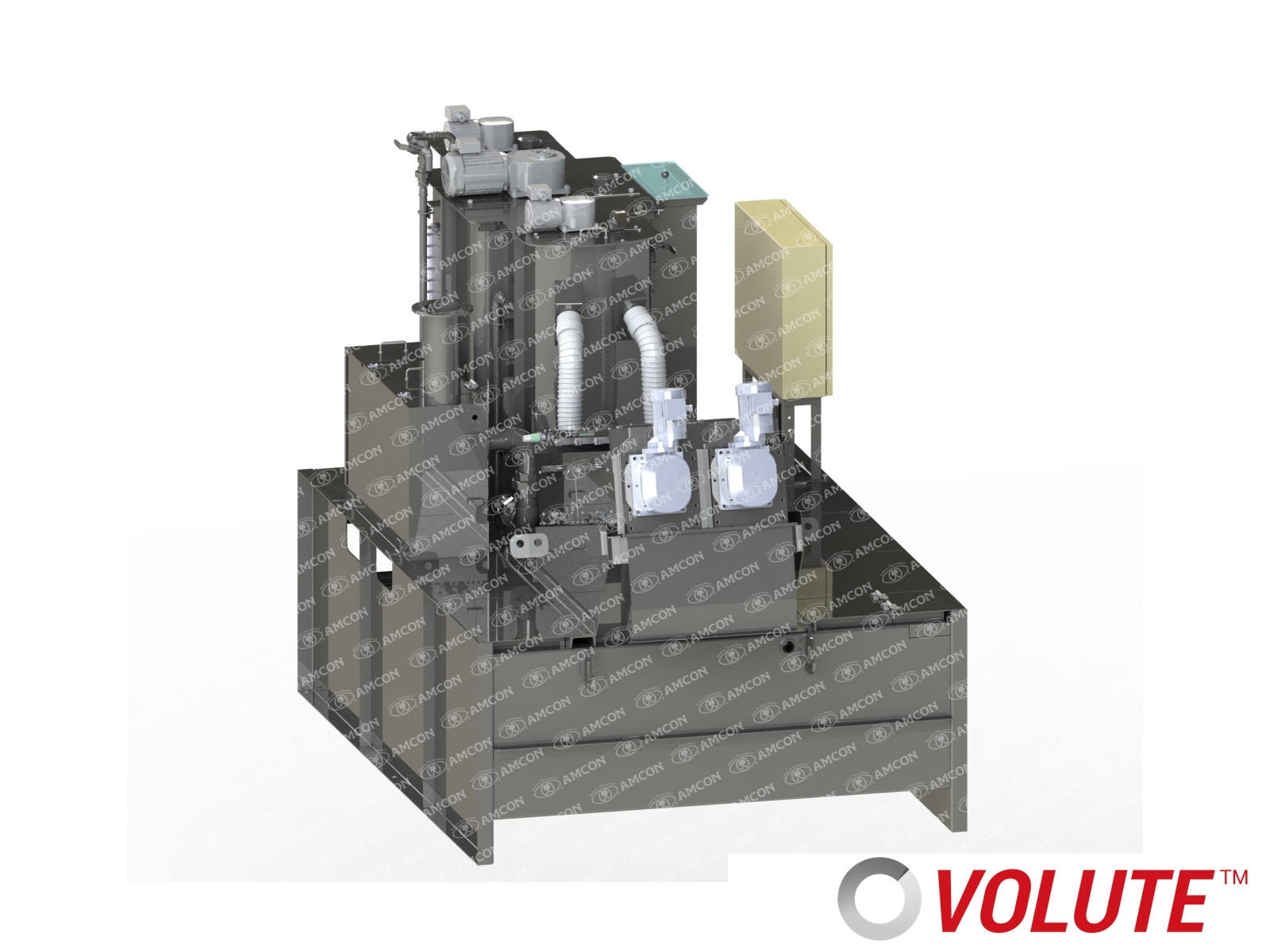

Excellent expandability

Excellent expandability

Additional cylinder unit can be added even after delivery

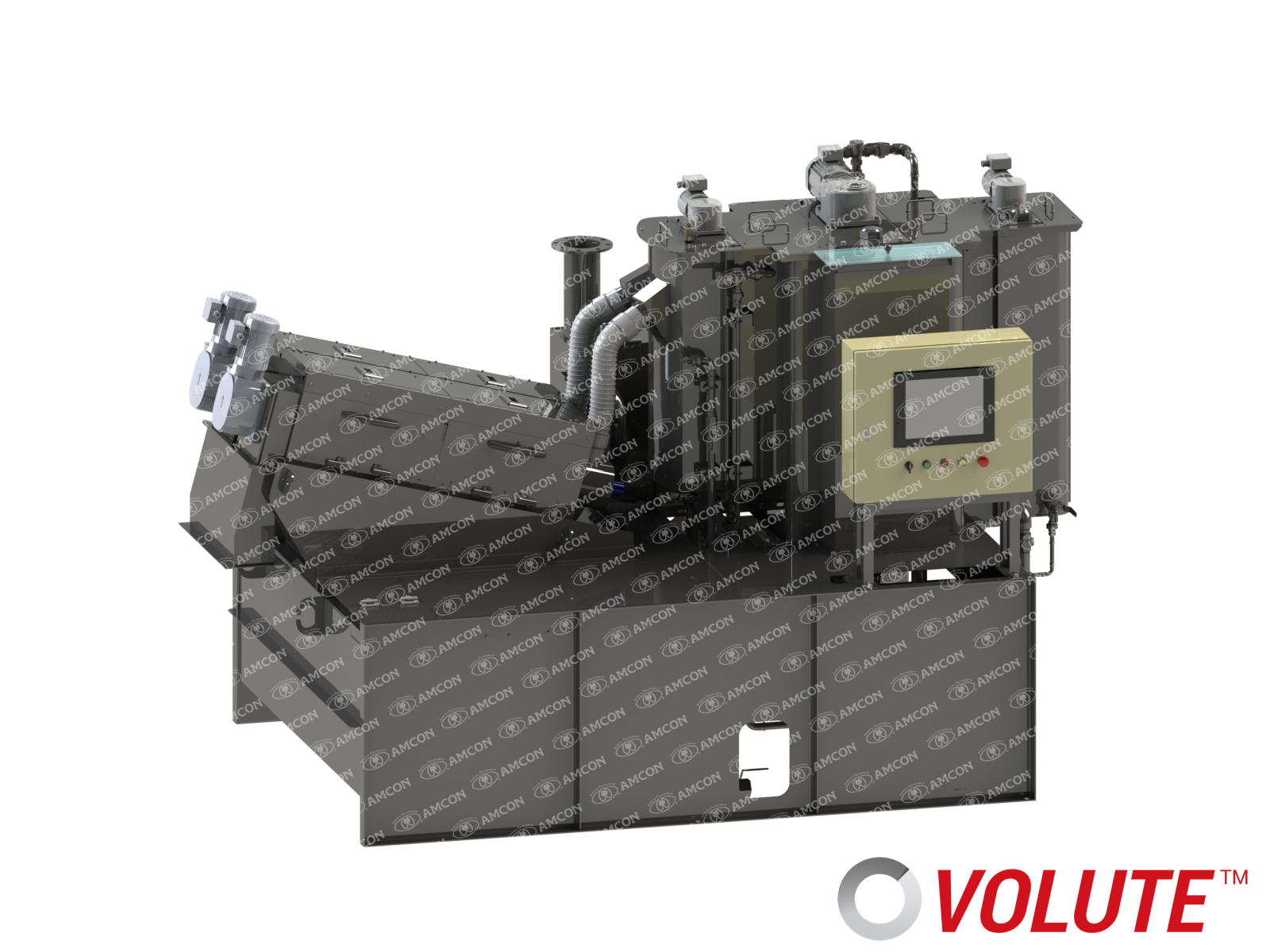

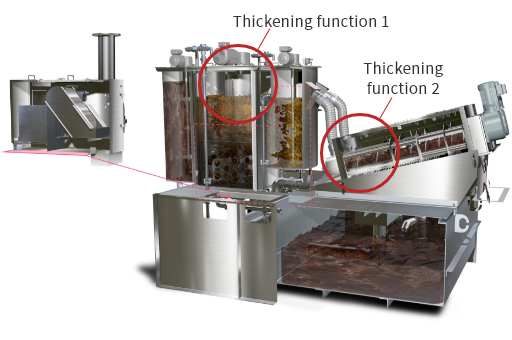

No pre-thickening required

This machine has an integrated structure in which two processes, thickening and dewatering, are handled by a single filter element, allowing the user to directly charge low-concentration sludge having a TS of about 0.2% without providing a thickening system in the preceding stage.

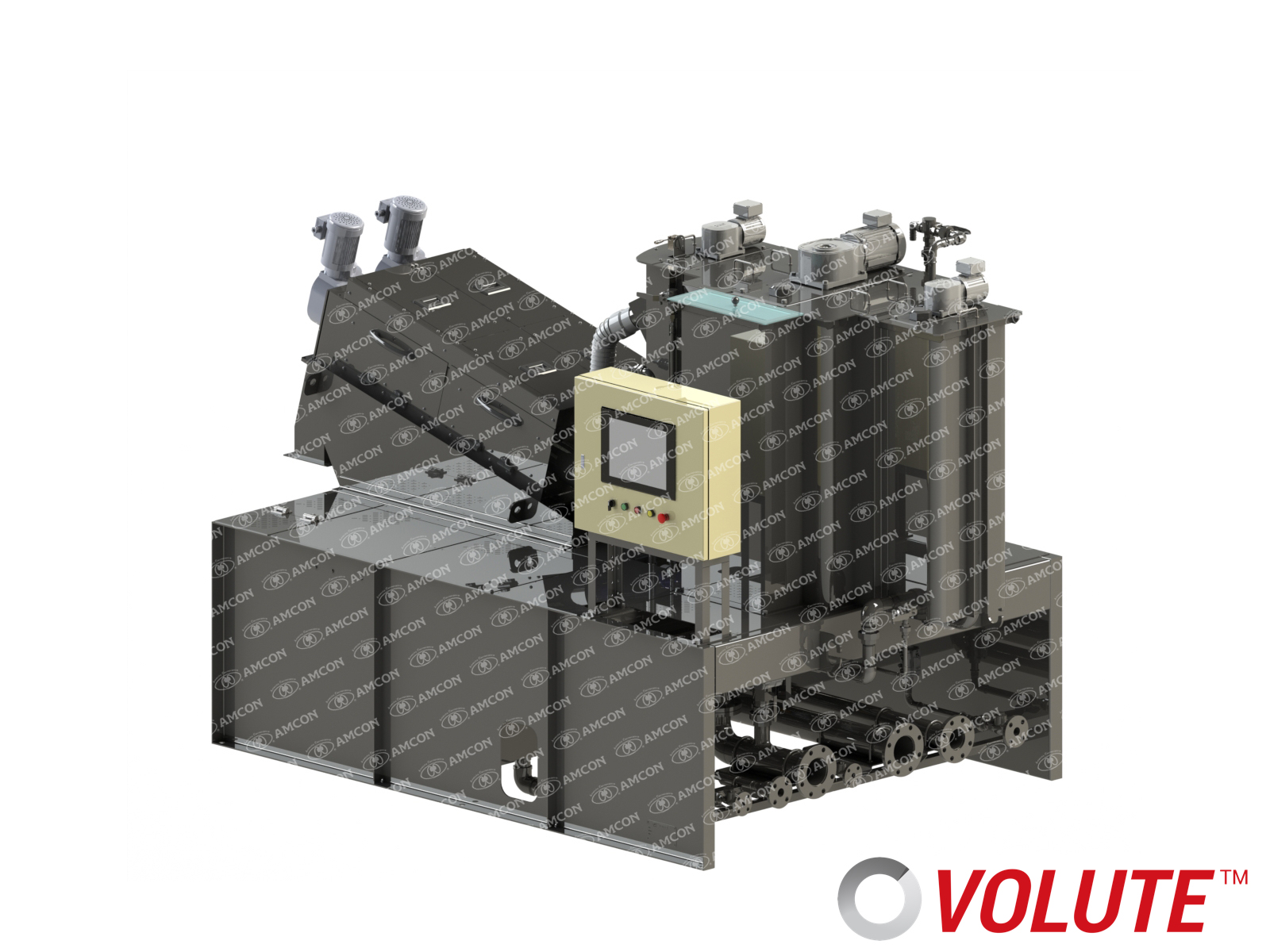

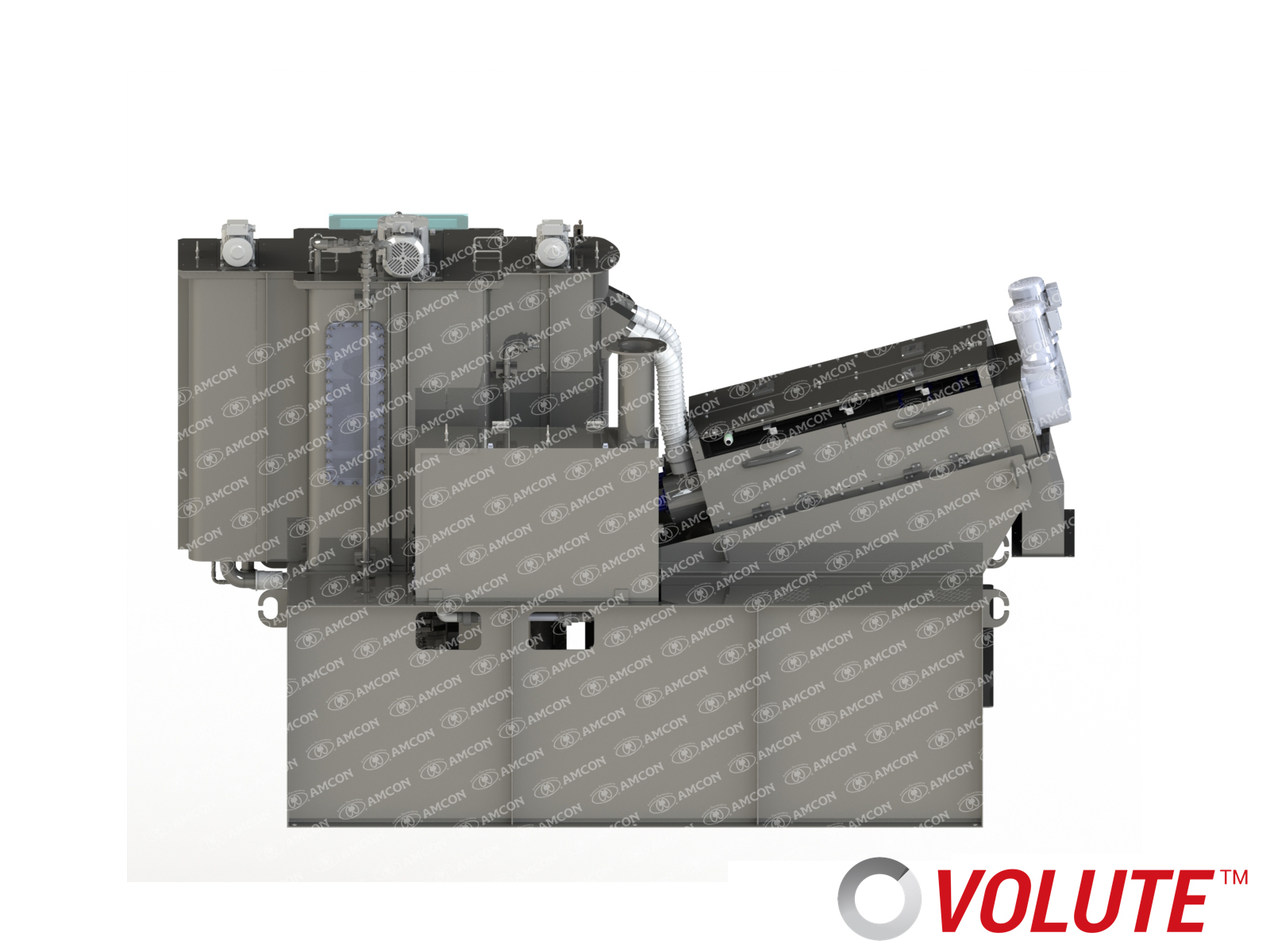

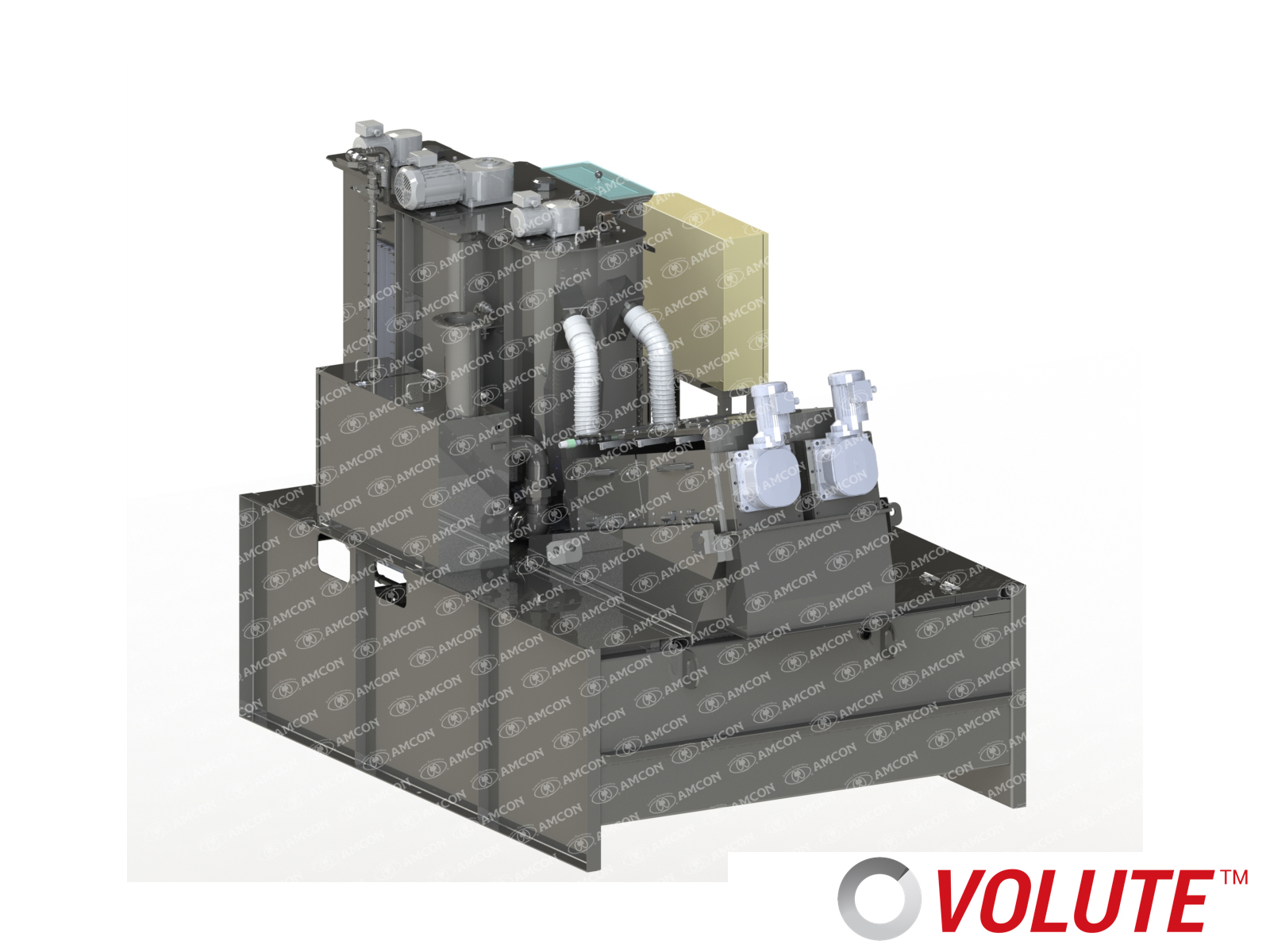

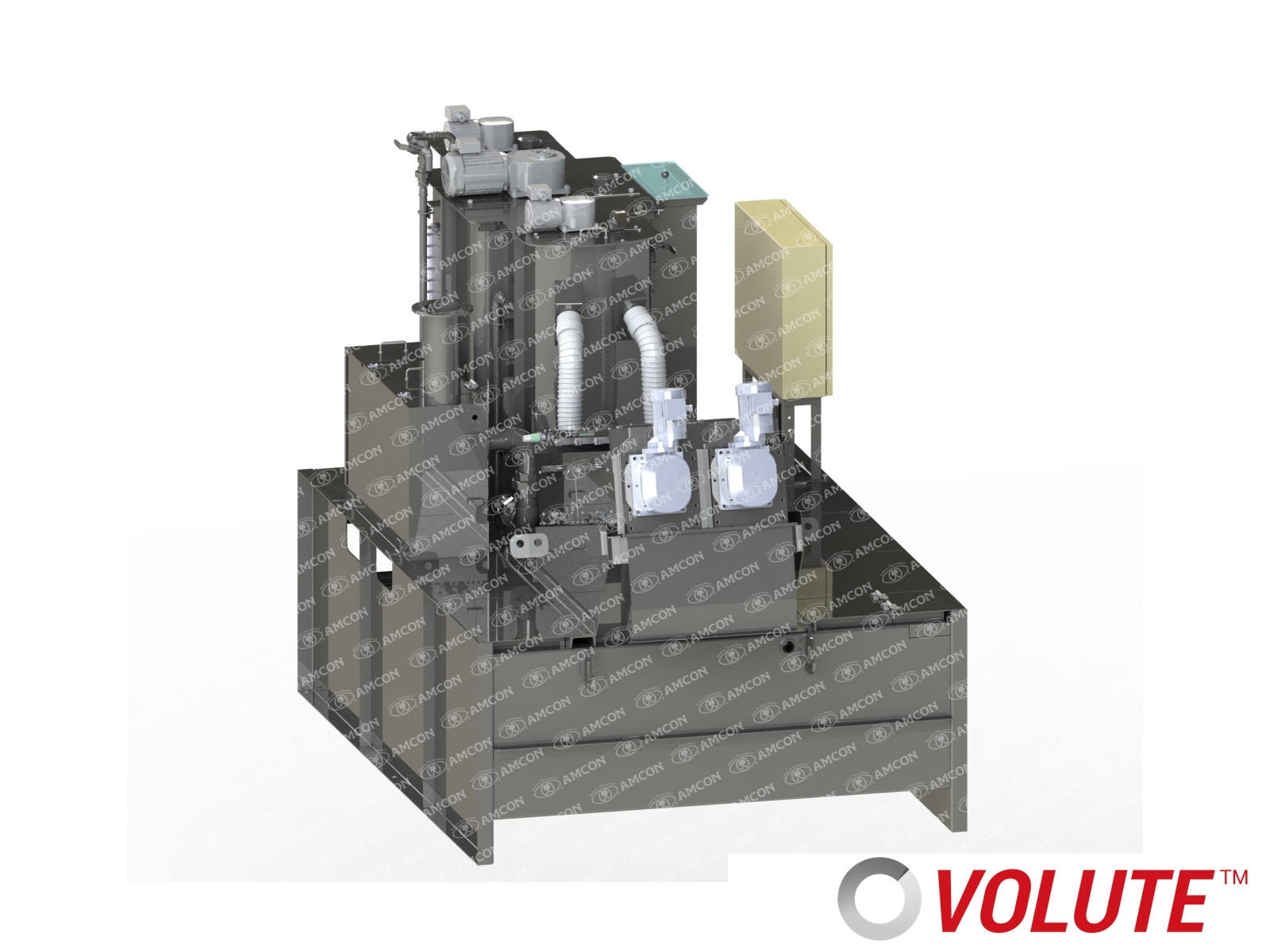

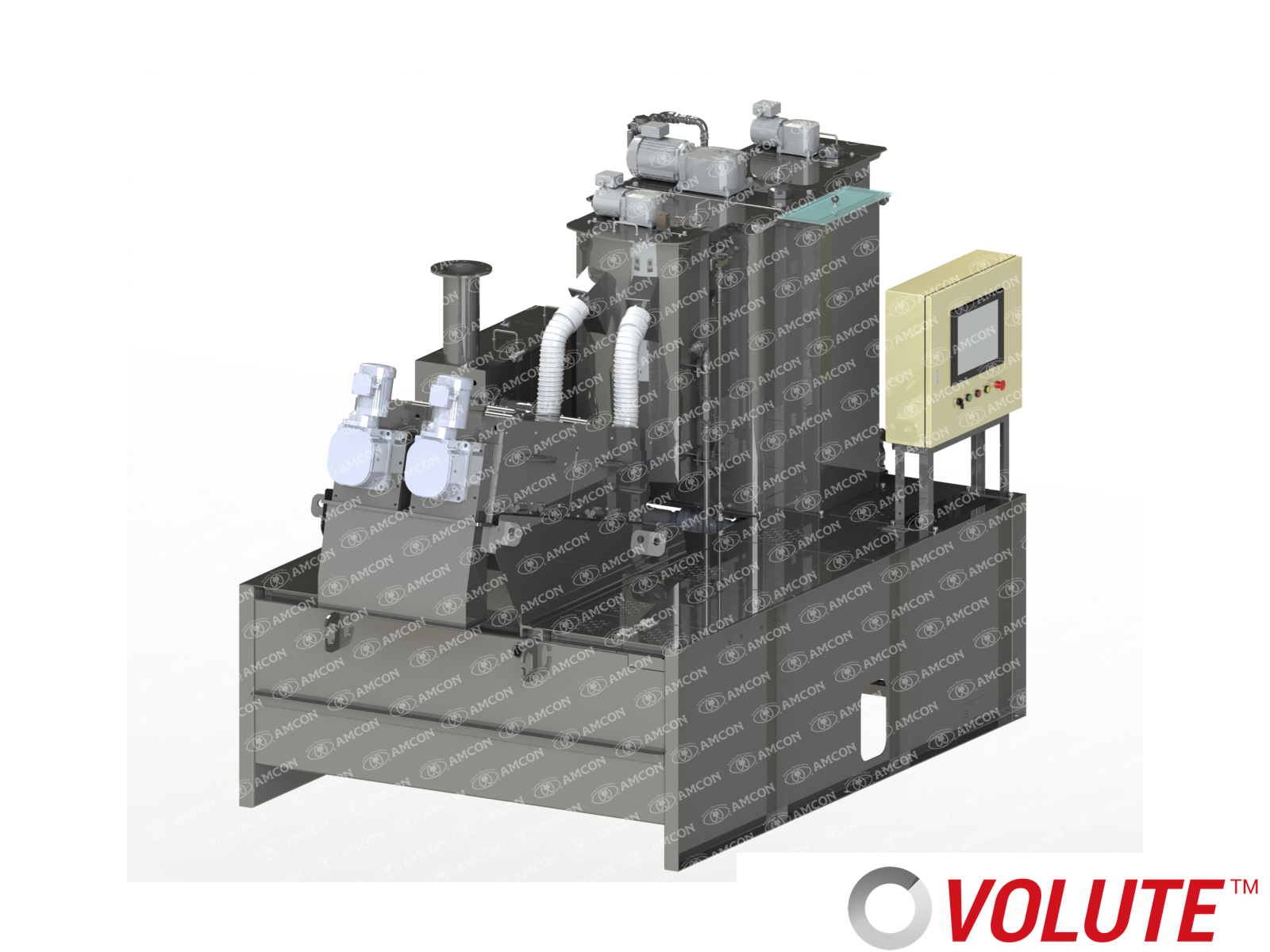

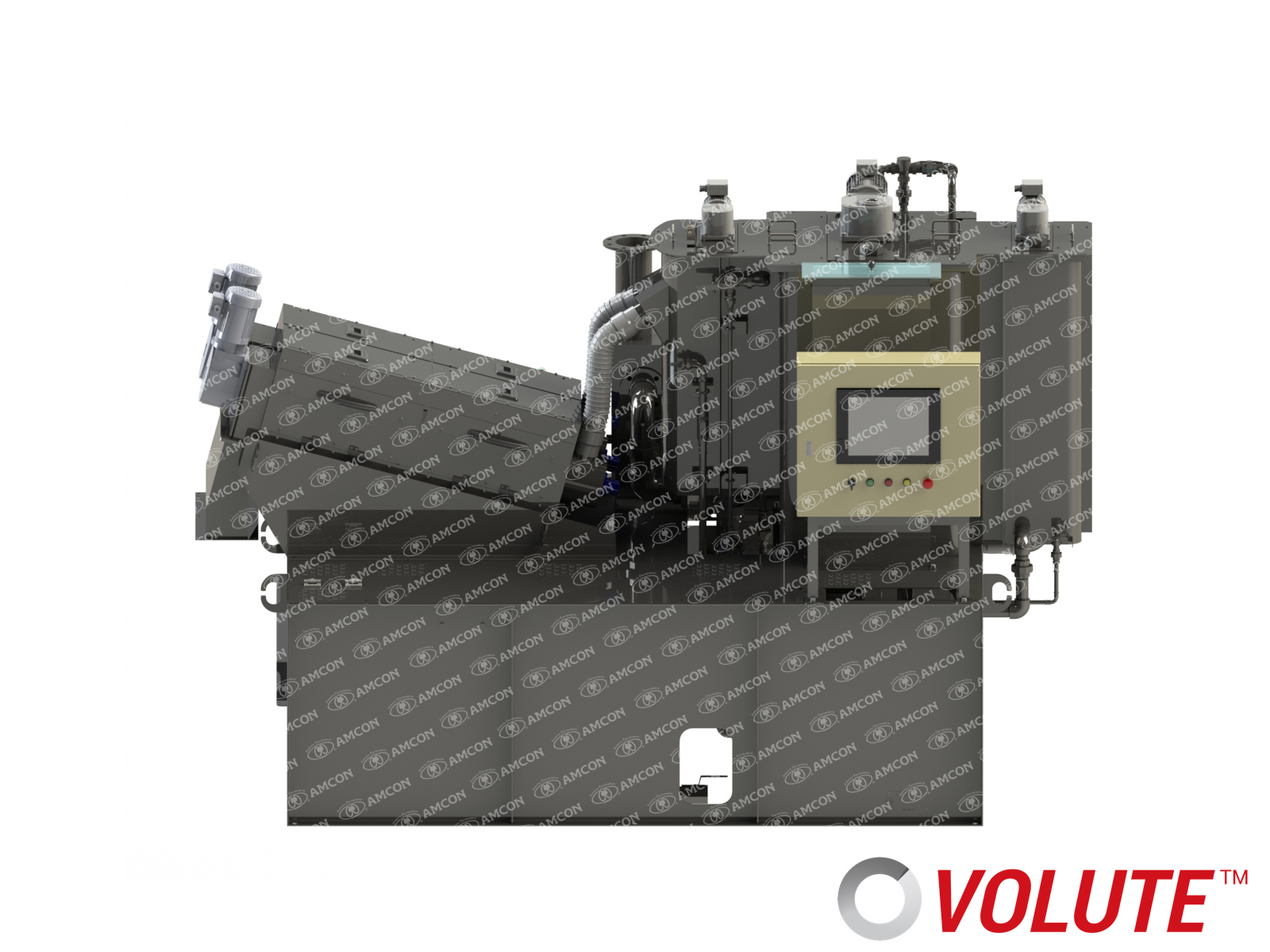

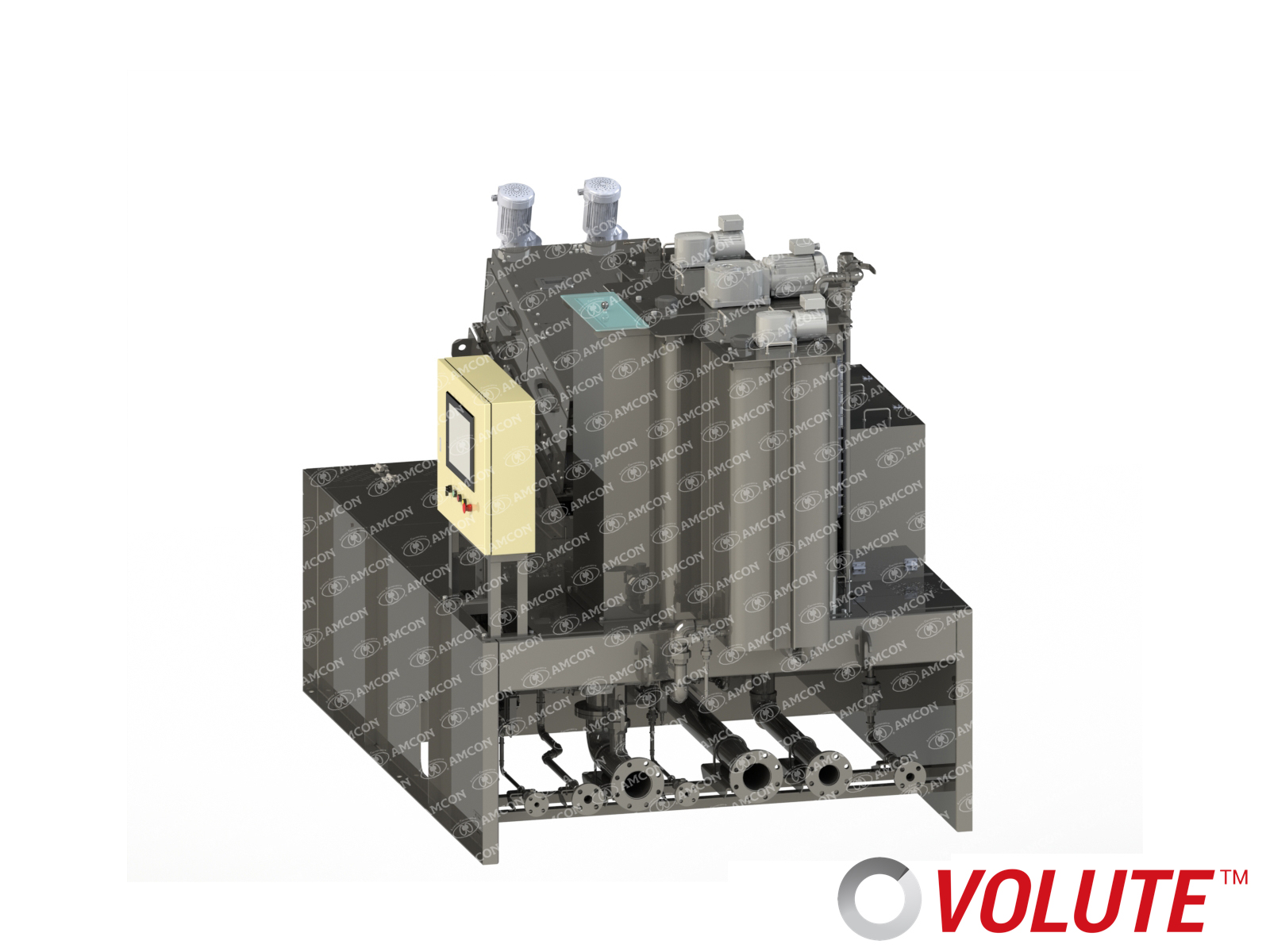

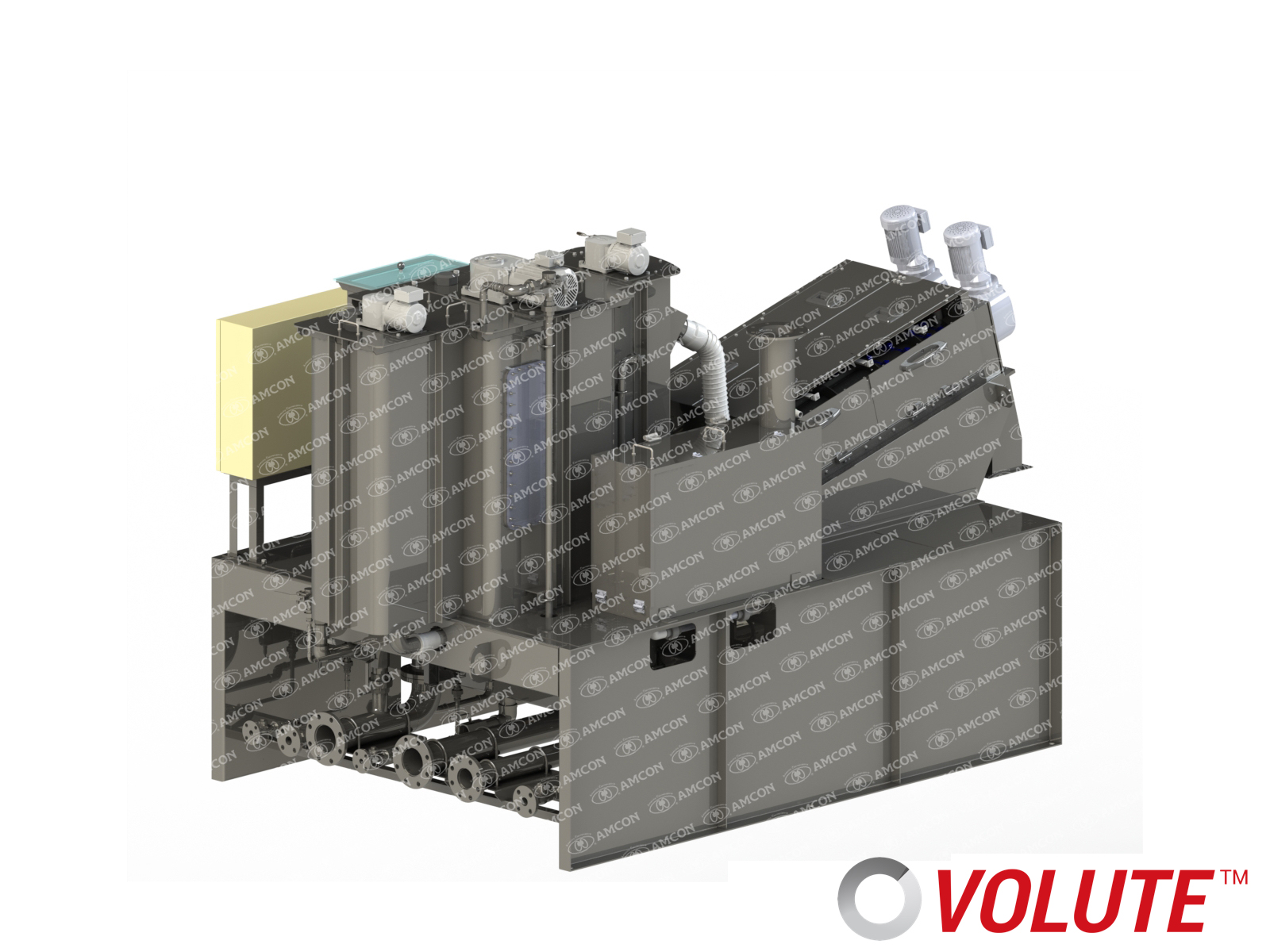

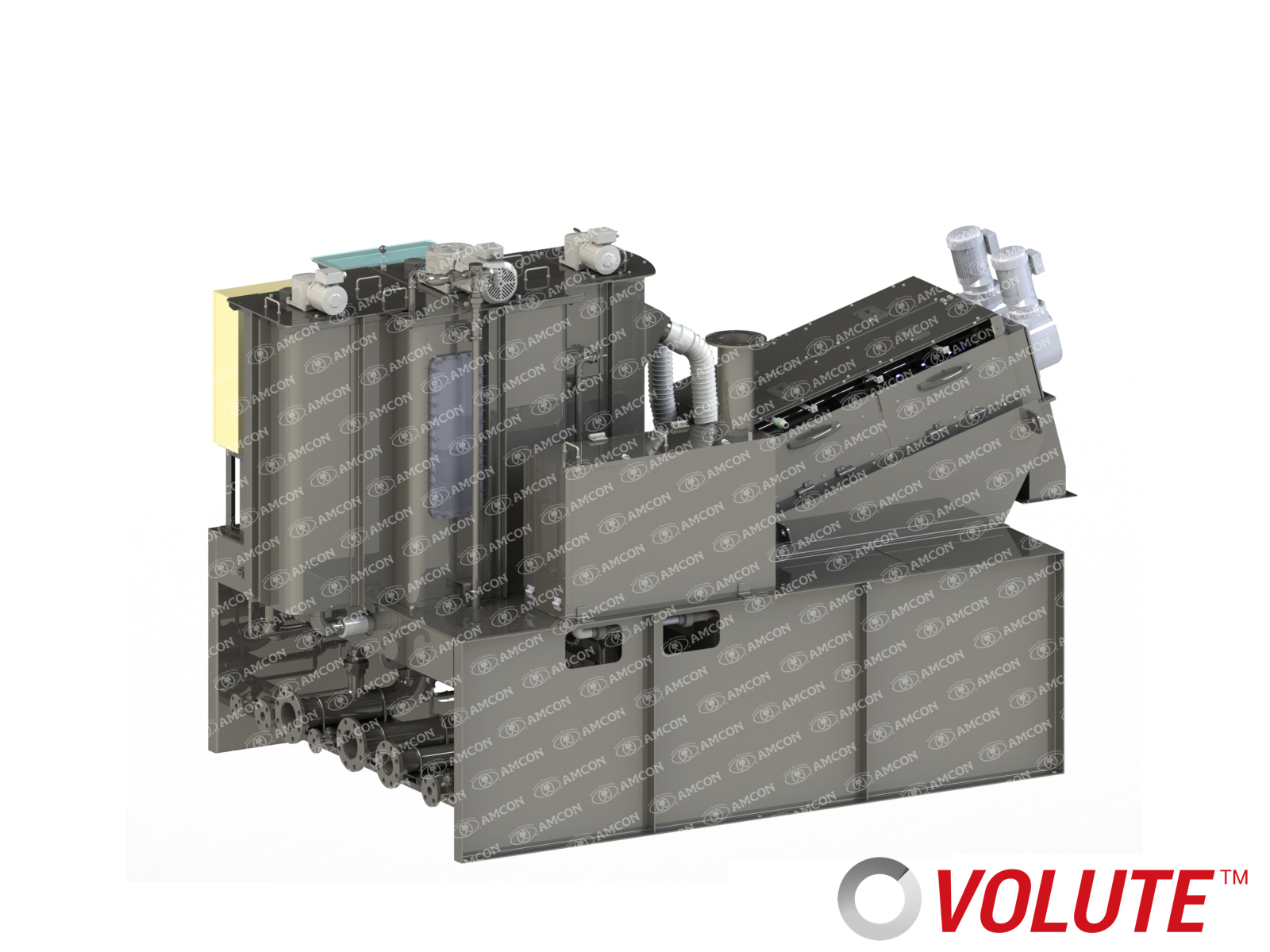

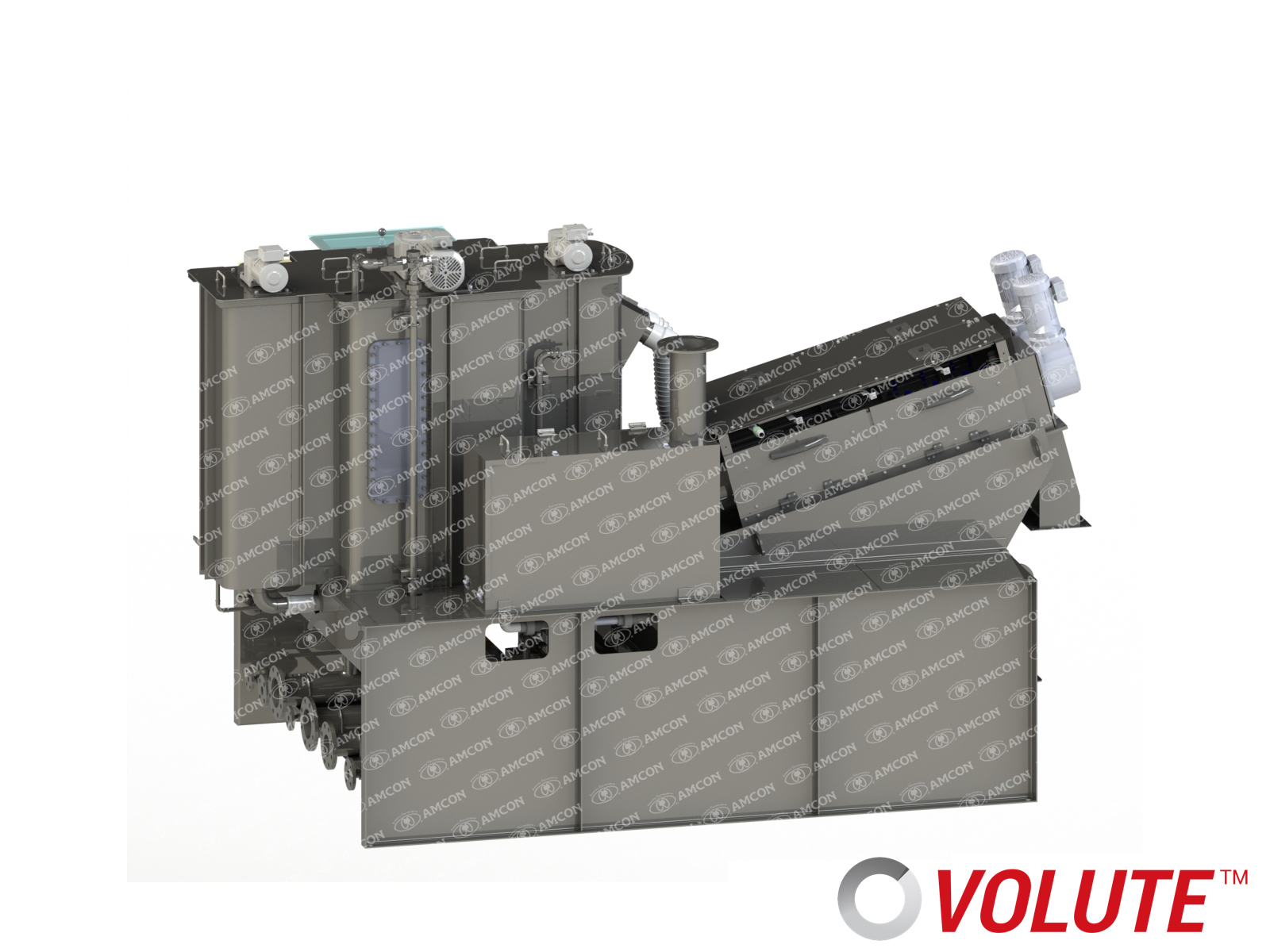

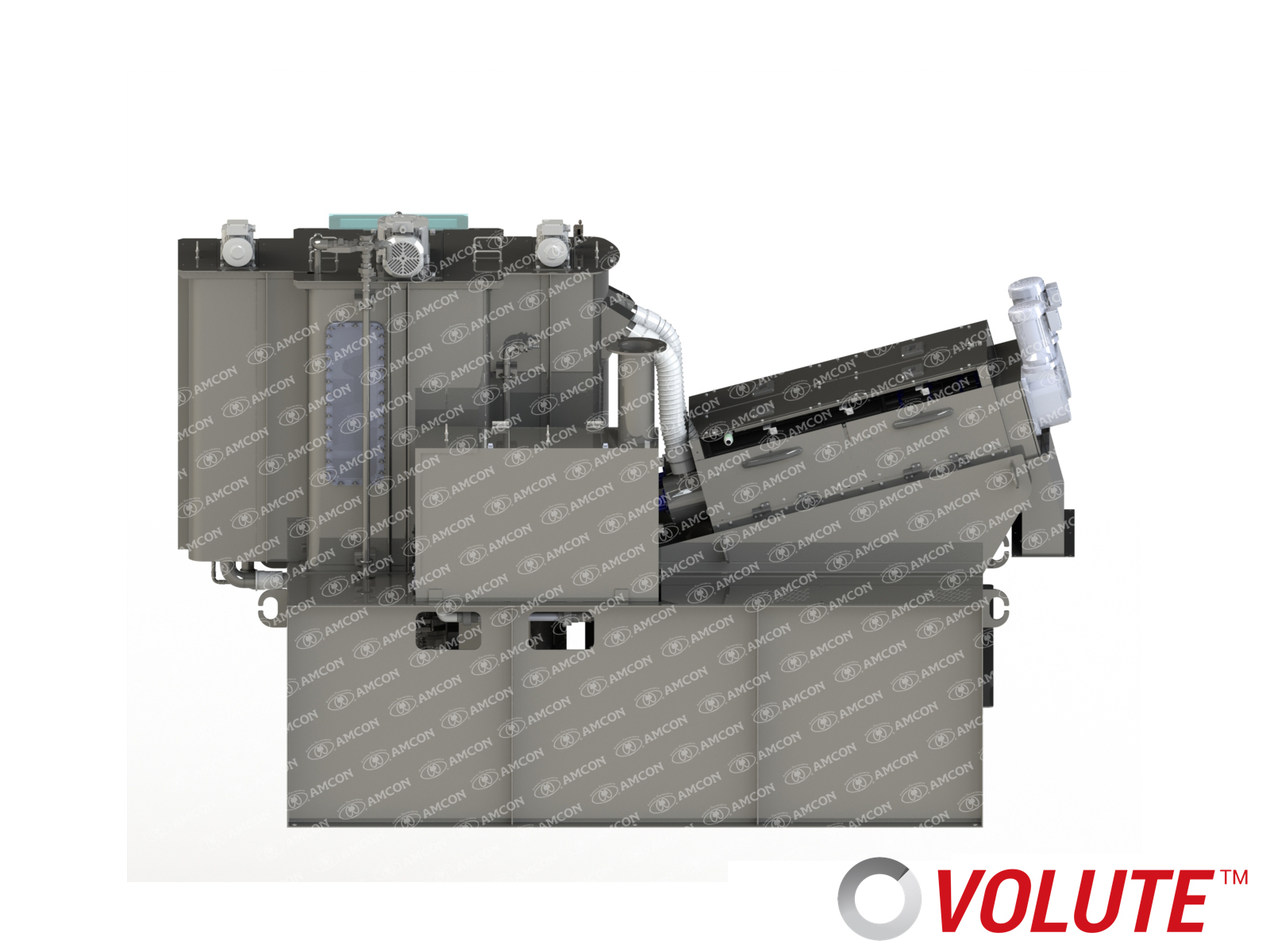

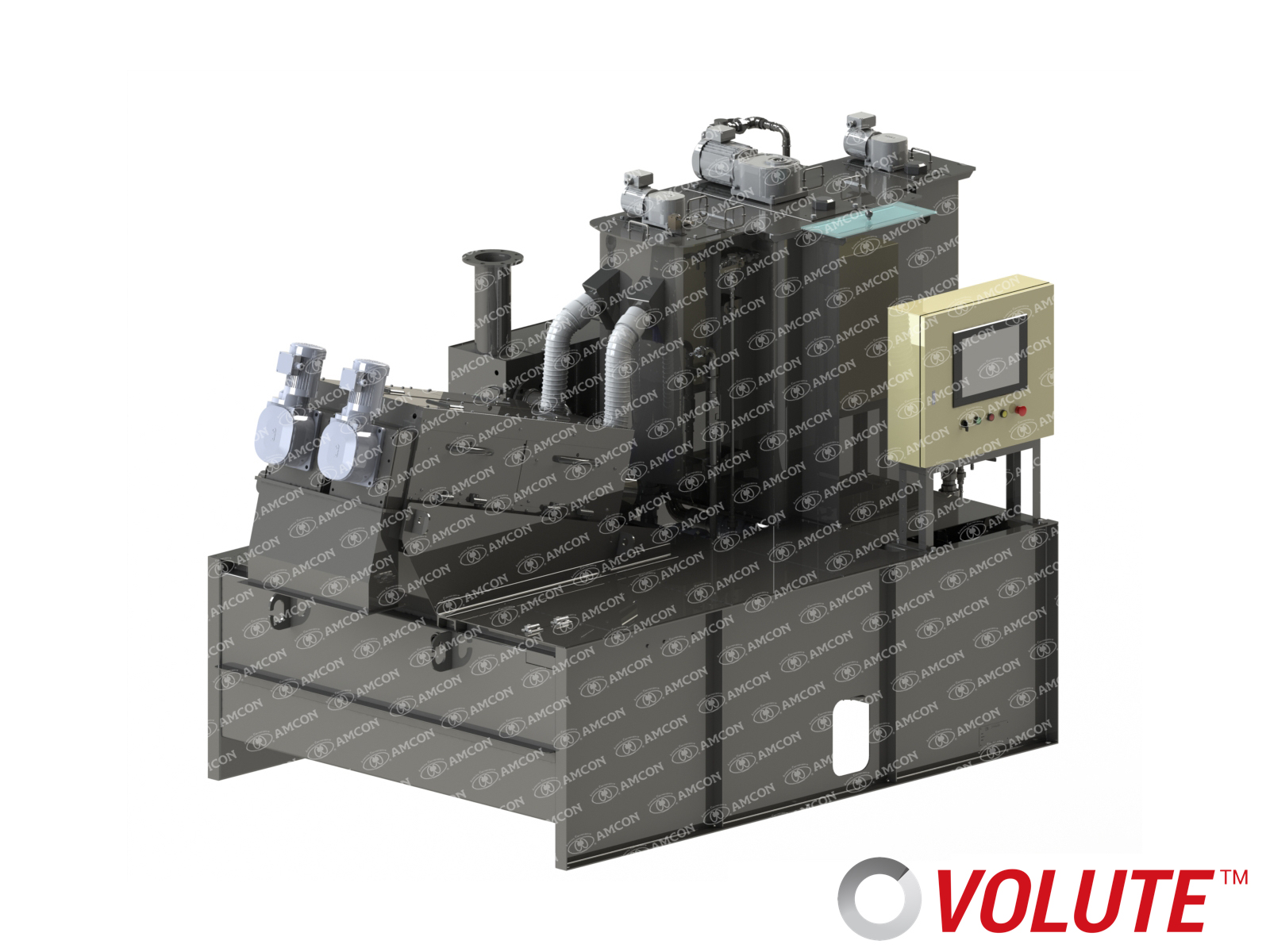

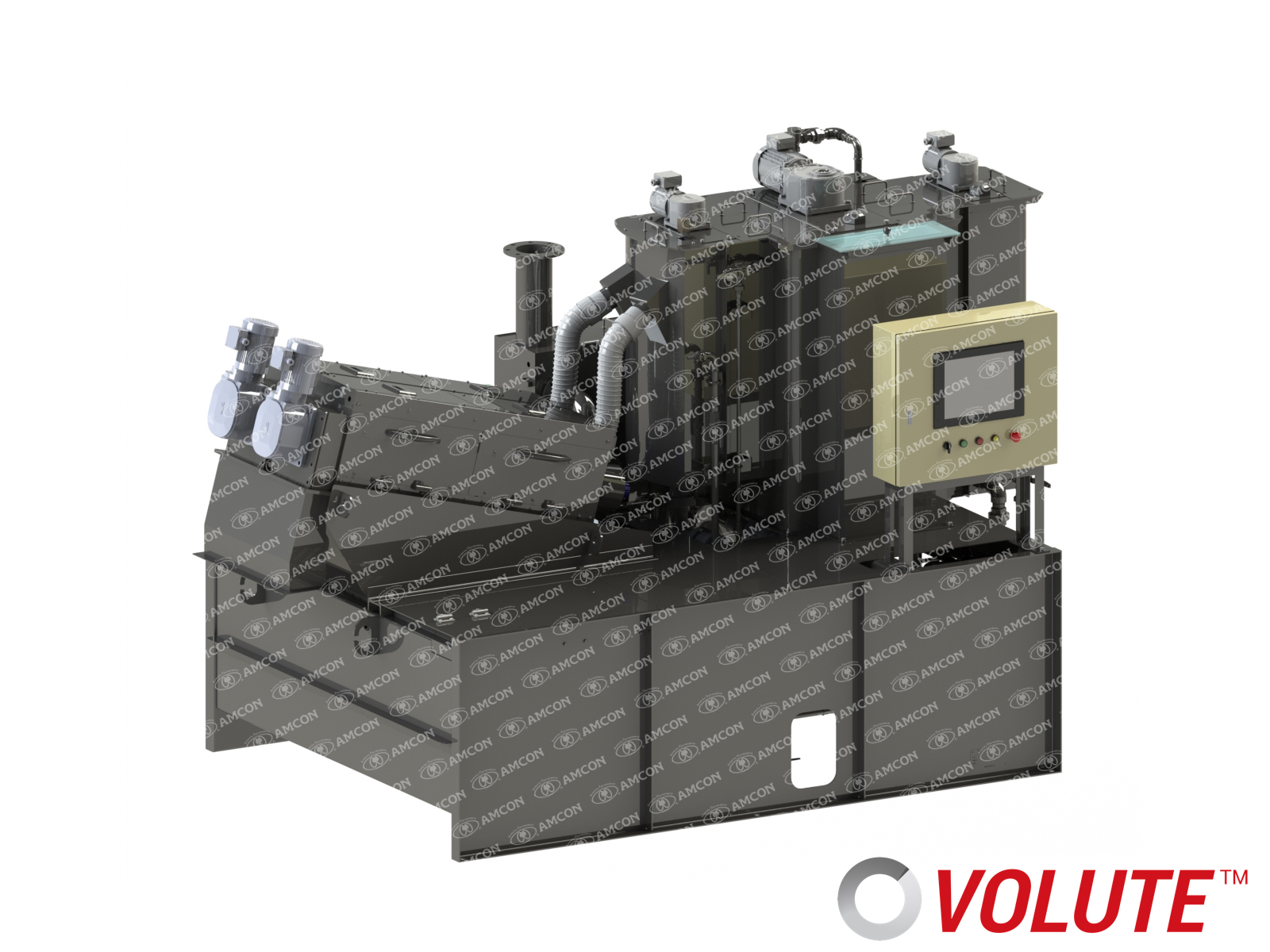

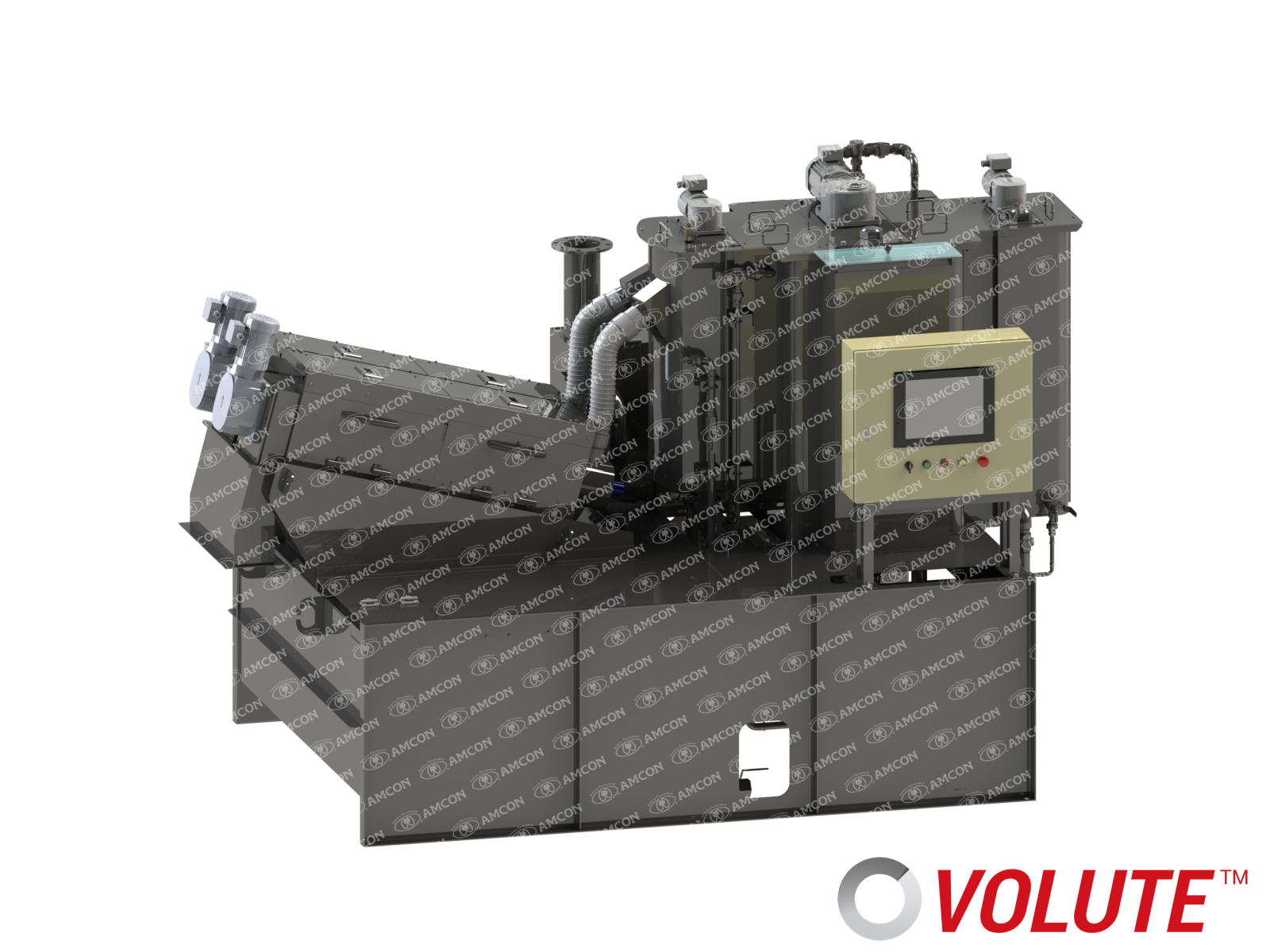

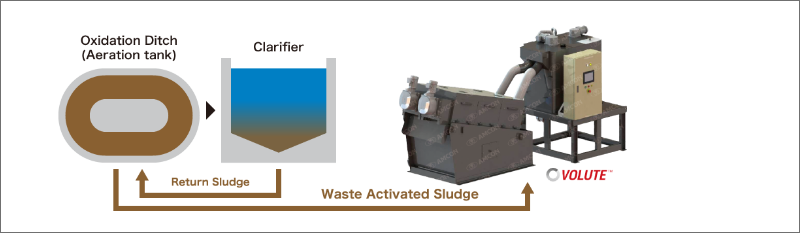

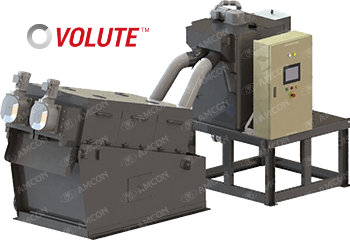

Revolution in sludge treatment VOLUTE™ introduced

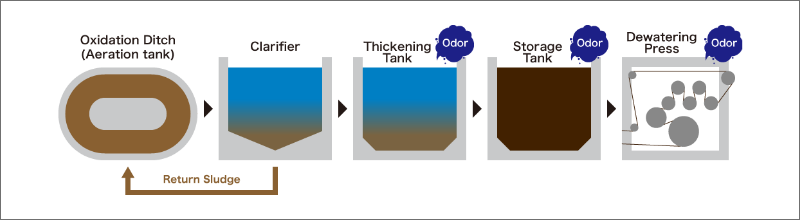

– Direct dewatering from oxidation ditch –

Since low-concentration sludge can be directly charged into the system, the oxidation ditch (aeration tank) direct dewatering process with VOLUTE™ has been widely employed in Japan as a sludge treatment method suitable for small-scale sewage treatment plants.

The direct dewatering from oxidation ditch was demonstrated for the first time ever in the world as a result of the joint research of Japan Sewage Works Agency and AMCON in 1998.

Advantages of the direct dewatering from oxidation ditch:

- Reduction in the construction and operating costs for thickening and storage equipment

- Odor reduction by dewatering fresh aerobic sludge

- Efficient recovery of phosphorus in waste activated sludge to the dewatered cake side, thereby reducing the load due to phosphorus returning to wastewater treatment

- Easy operation and management of the sludge dewatering press due to small concentration fluctuations in the oxidation ditch (aeration tank)

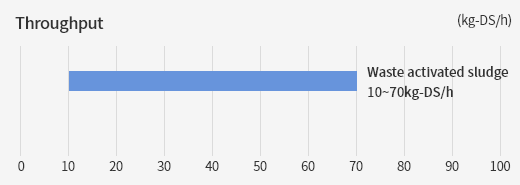

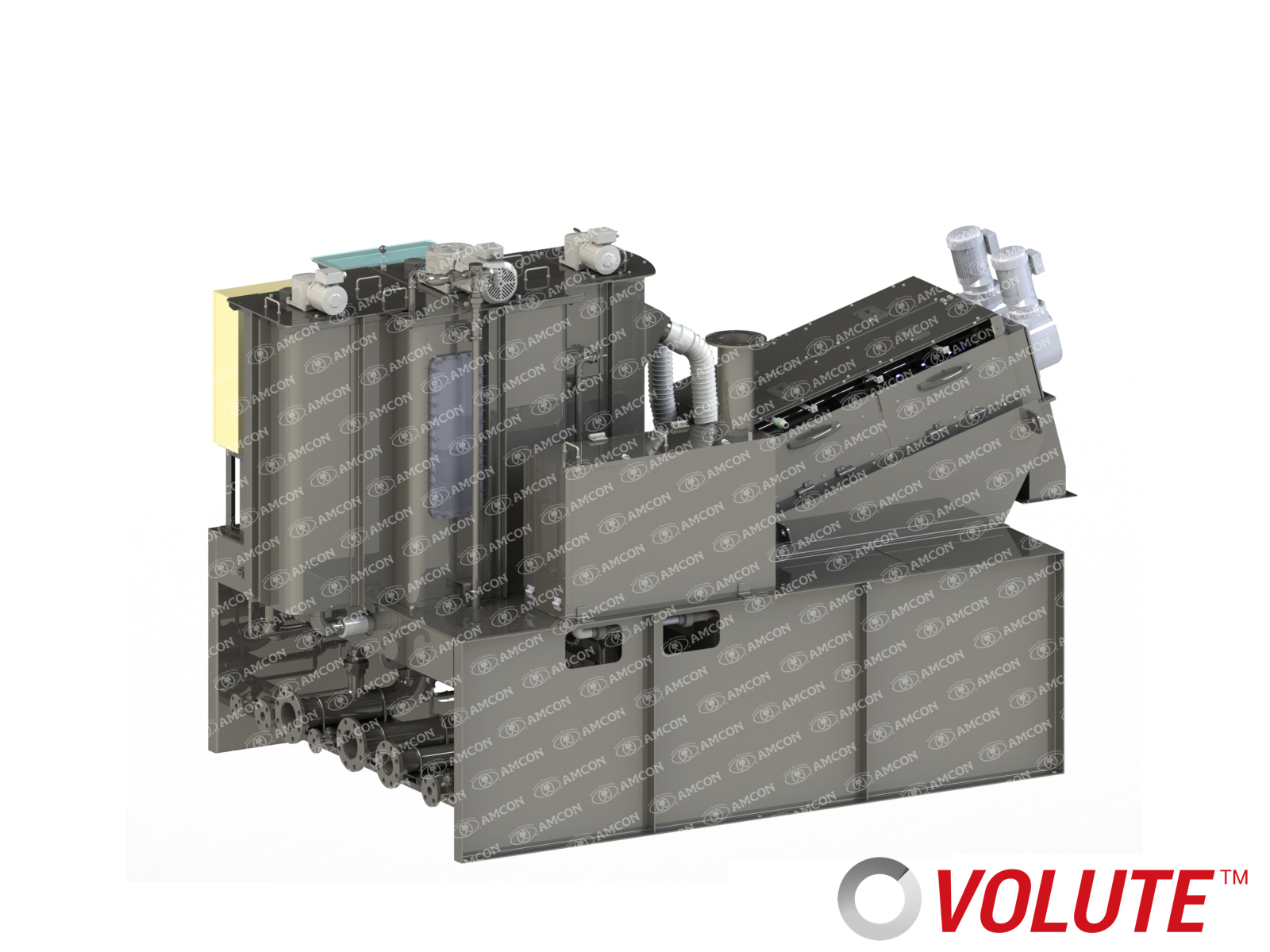

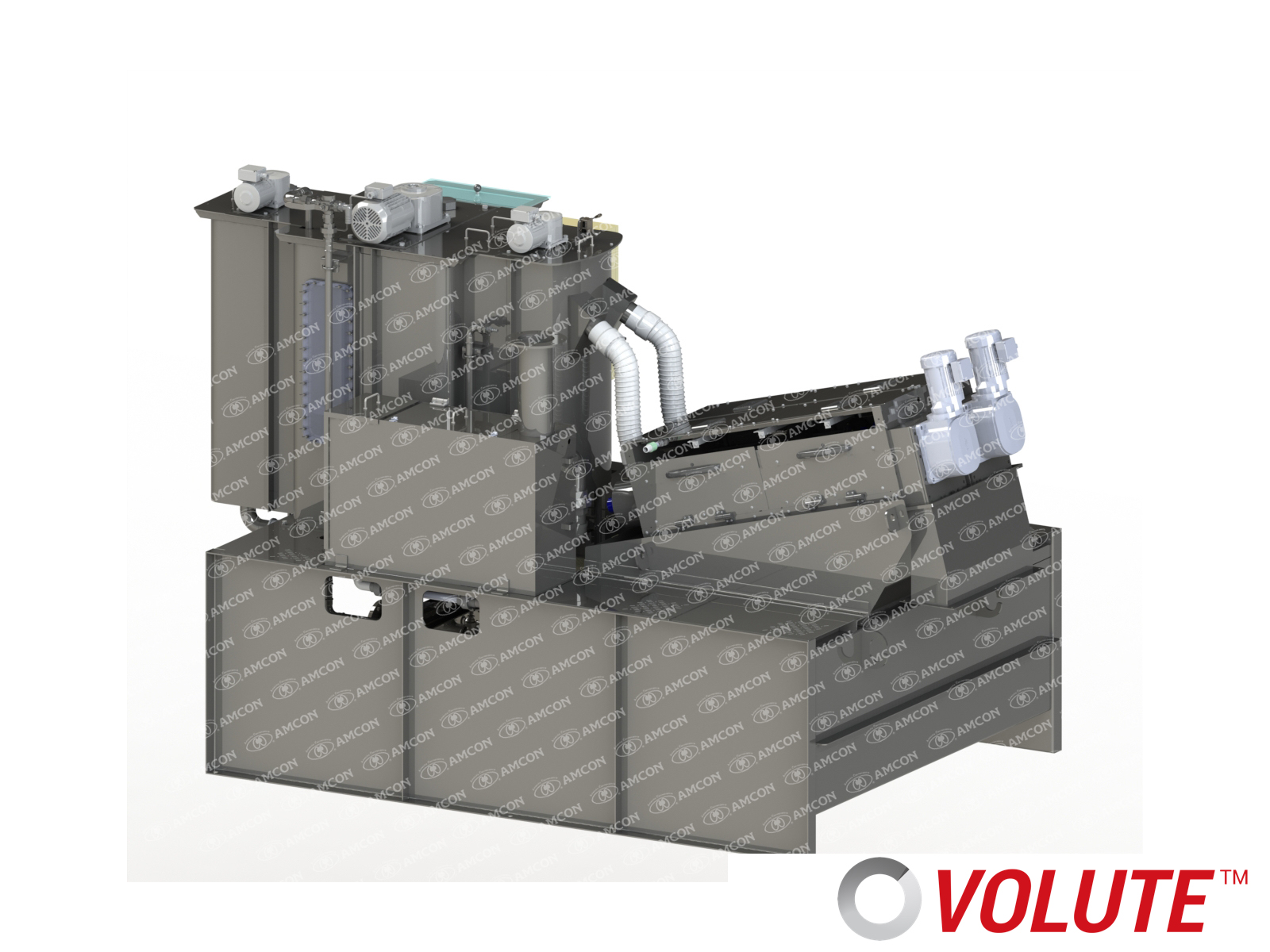

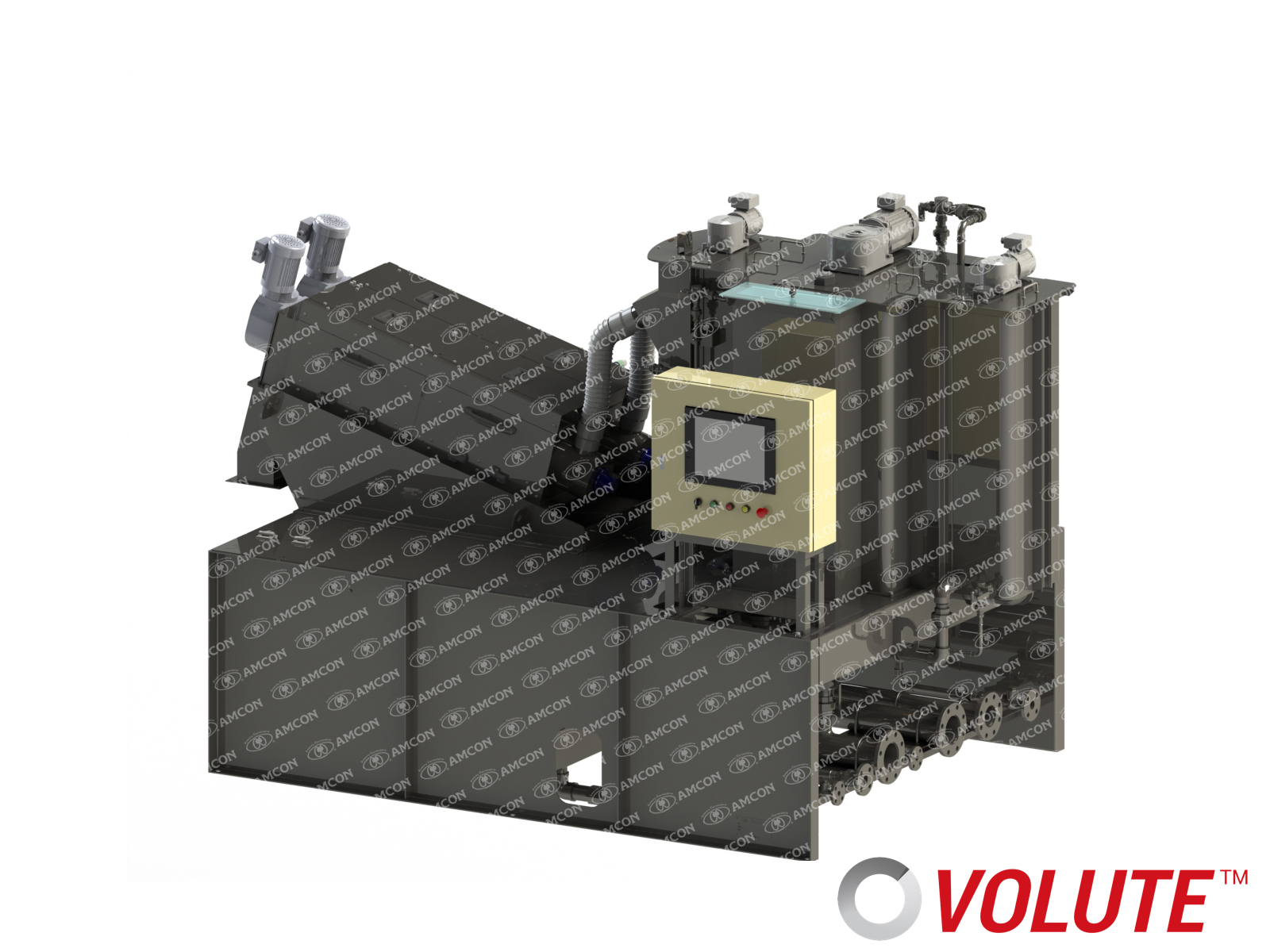

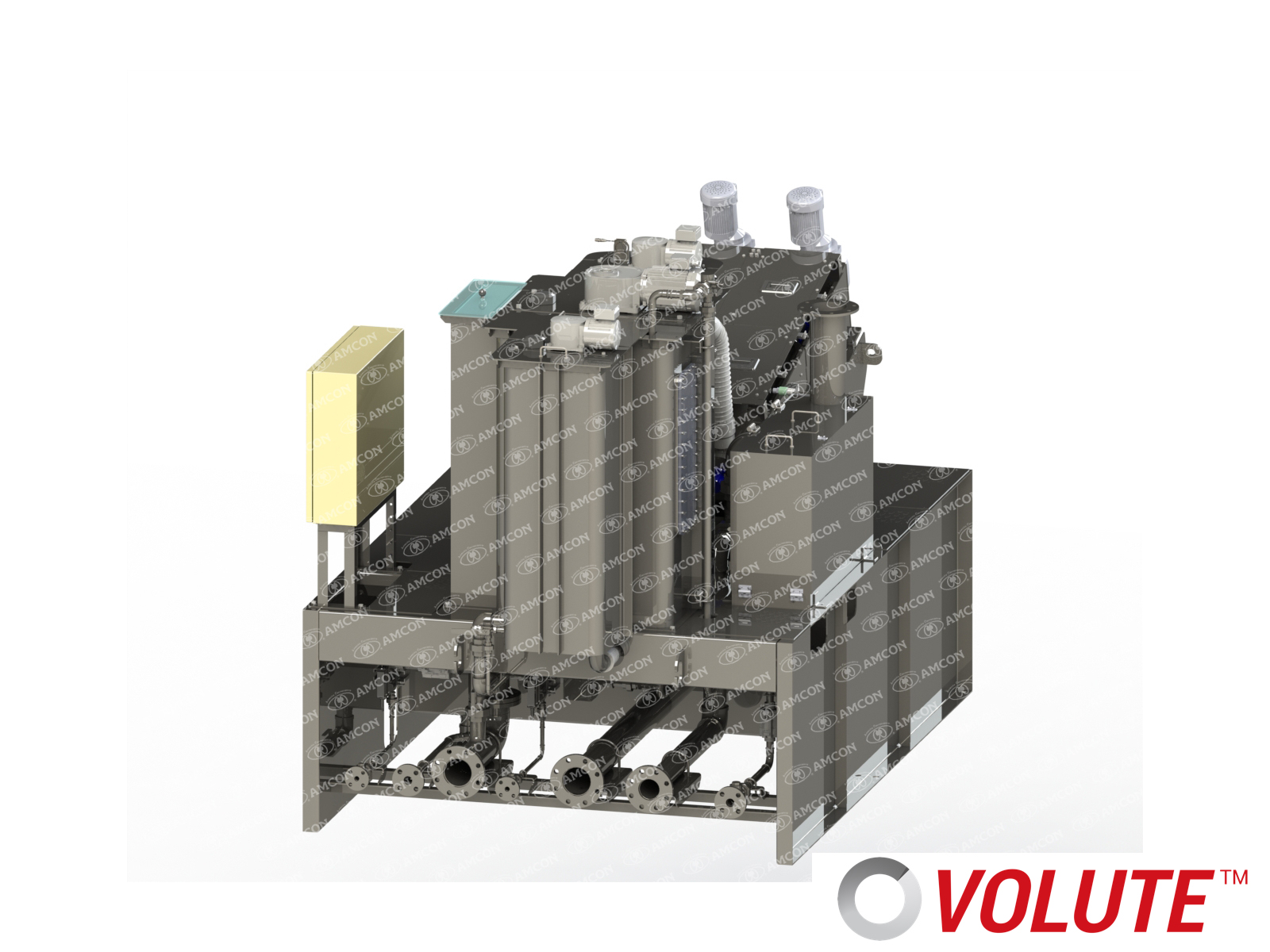

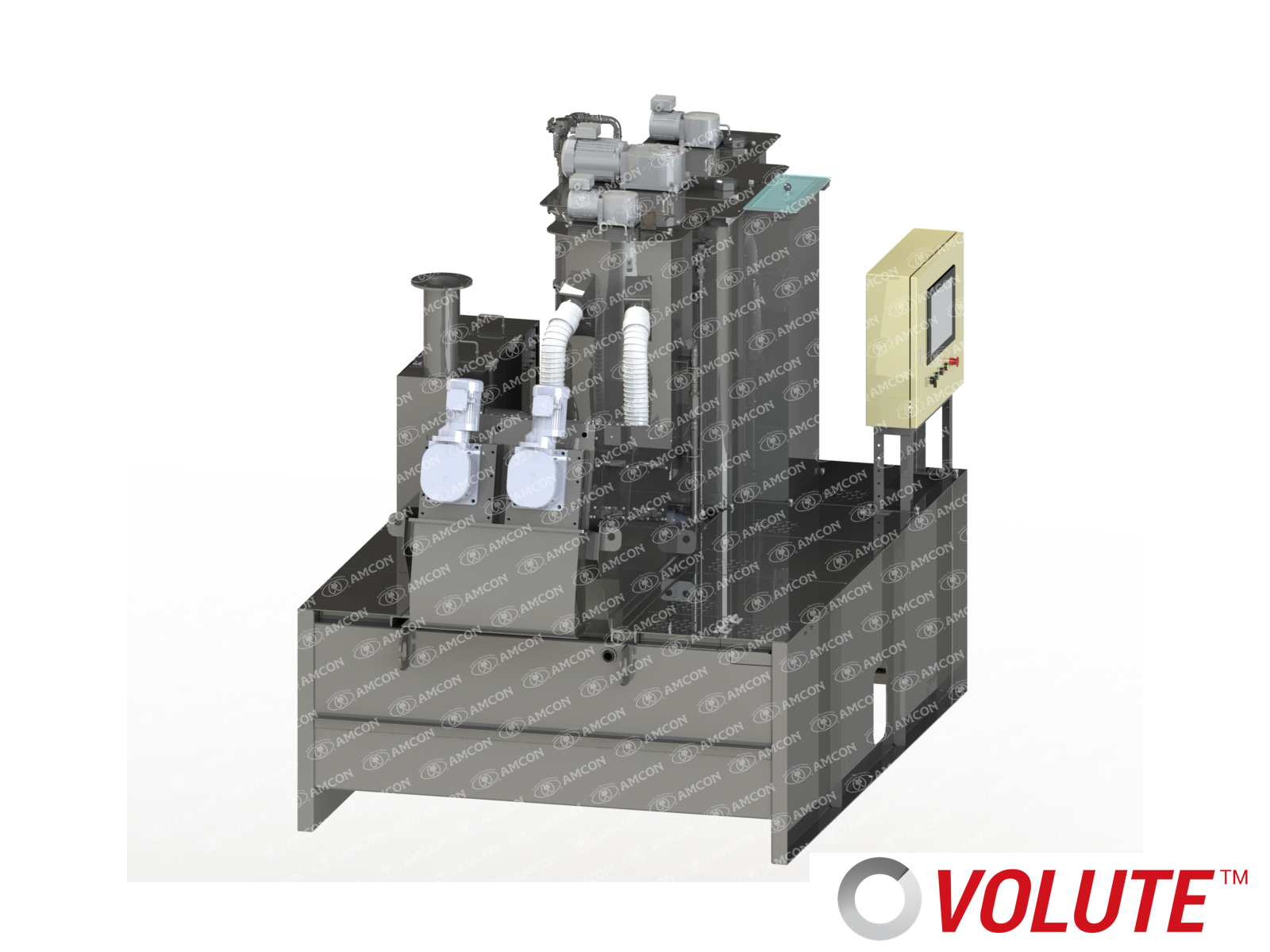

Improved throughput has reduced the life cycle cost

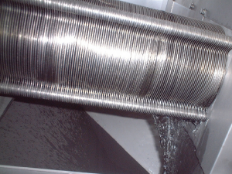

Two thickening functions are installed in the Thickening Flocculation Tank and then in the VOLUTE™ cylinder.

When the water content of the dewatered cake is set at the same level as that of the conventional machine, the throughput has been improved by approximately 50%.

This enables a reduction in the life cycle cost by reducing the system size.

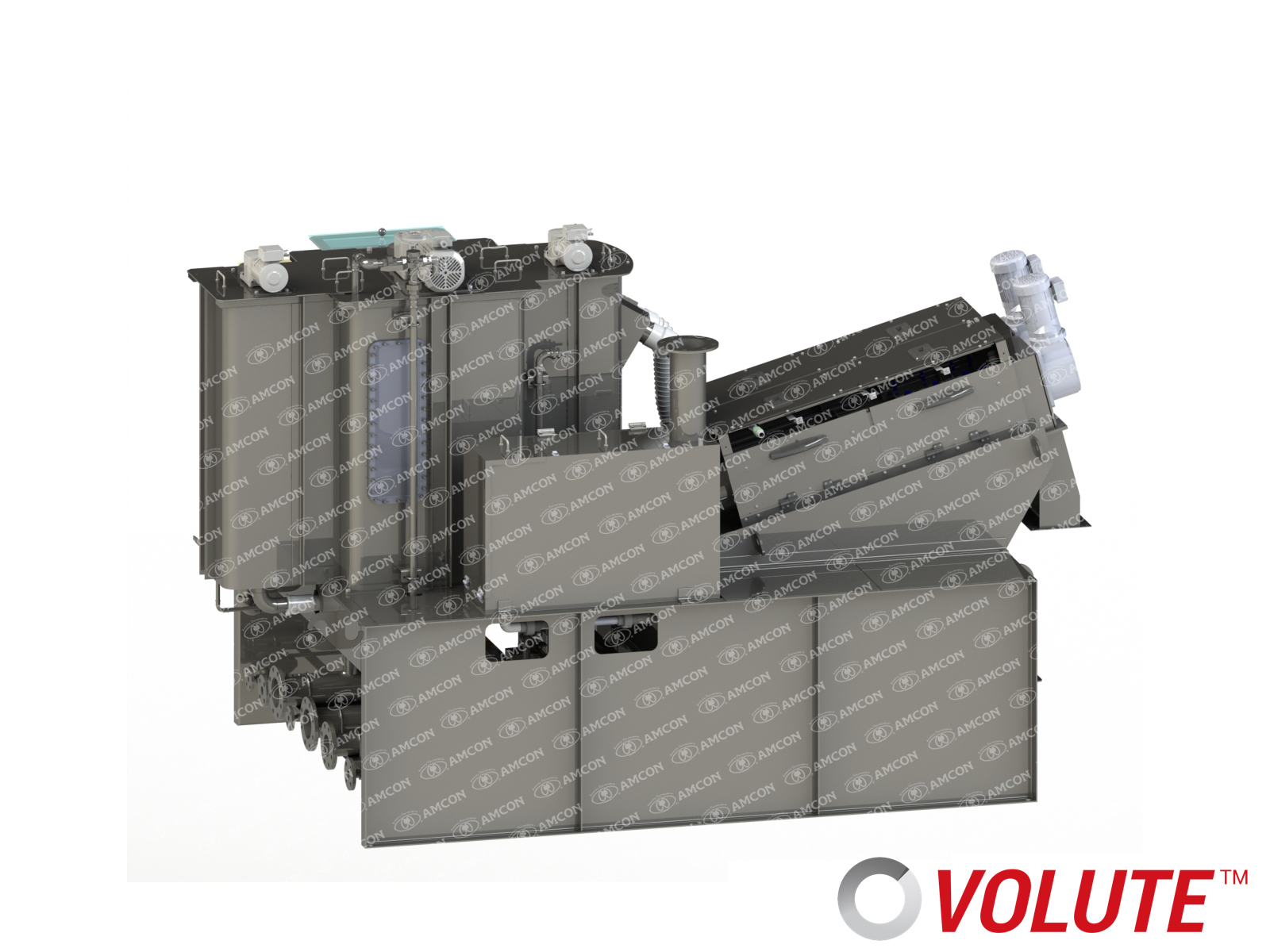

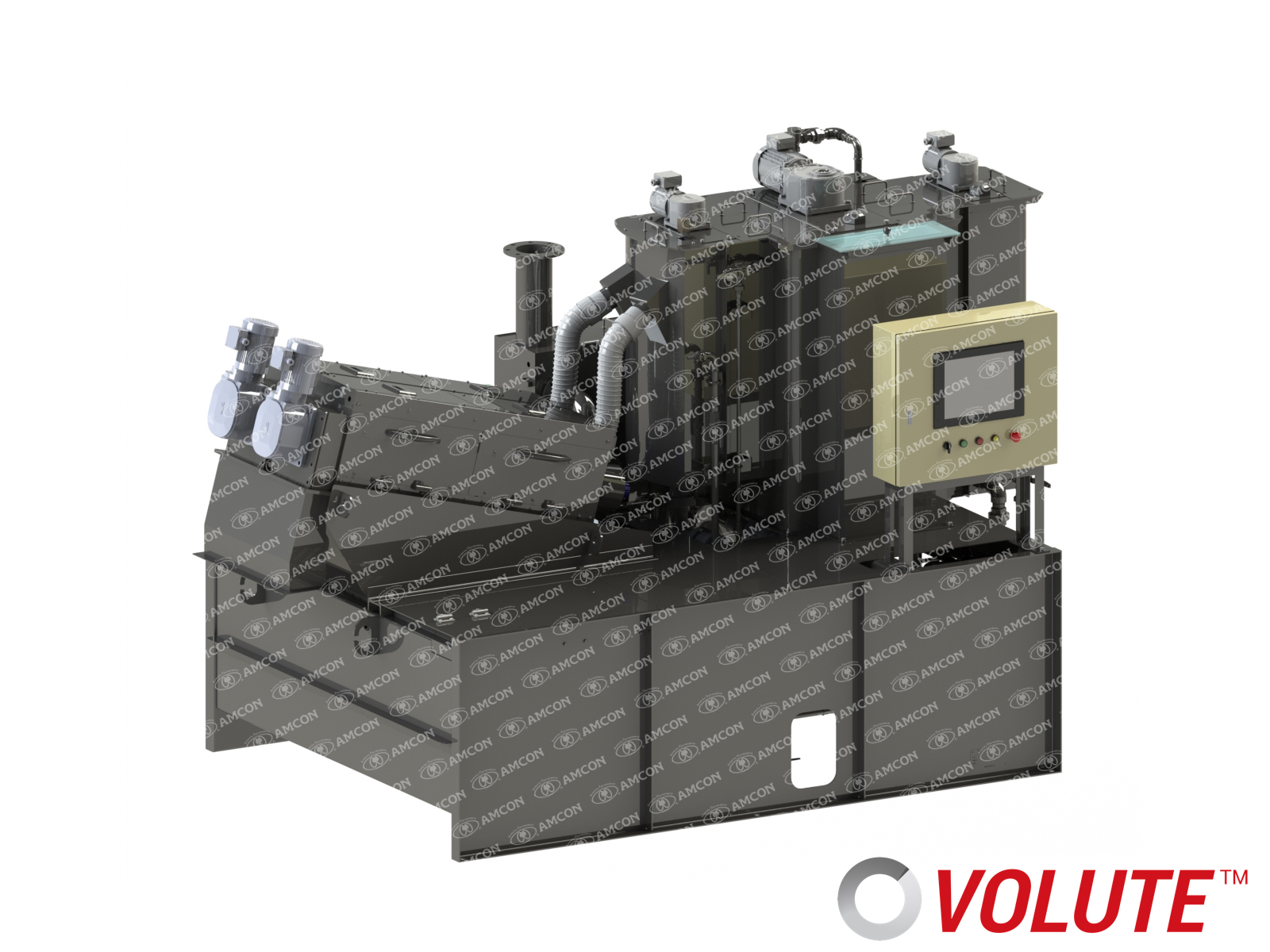

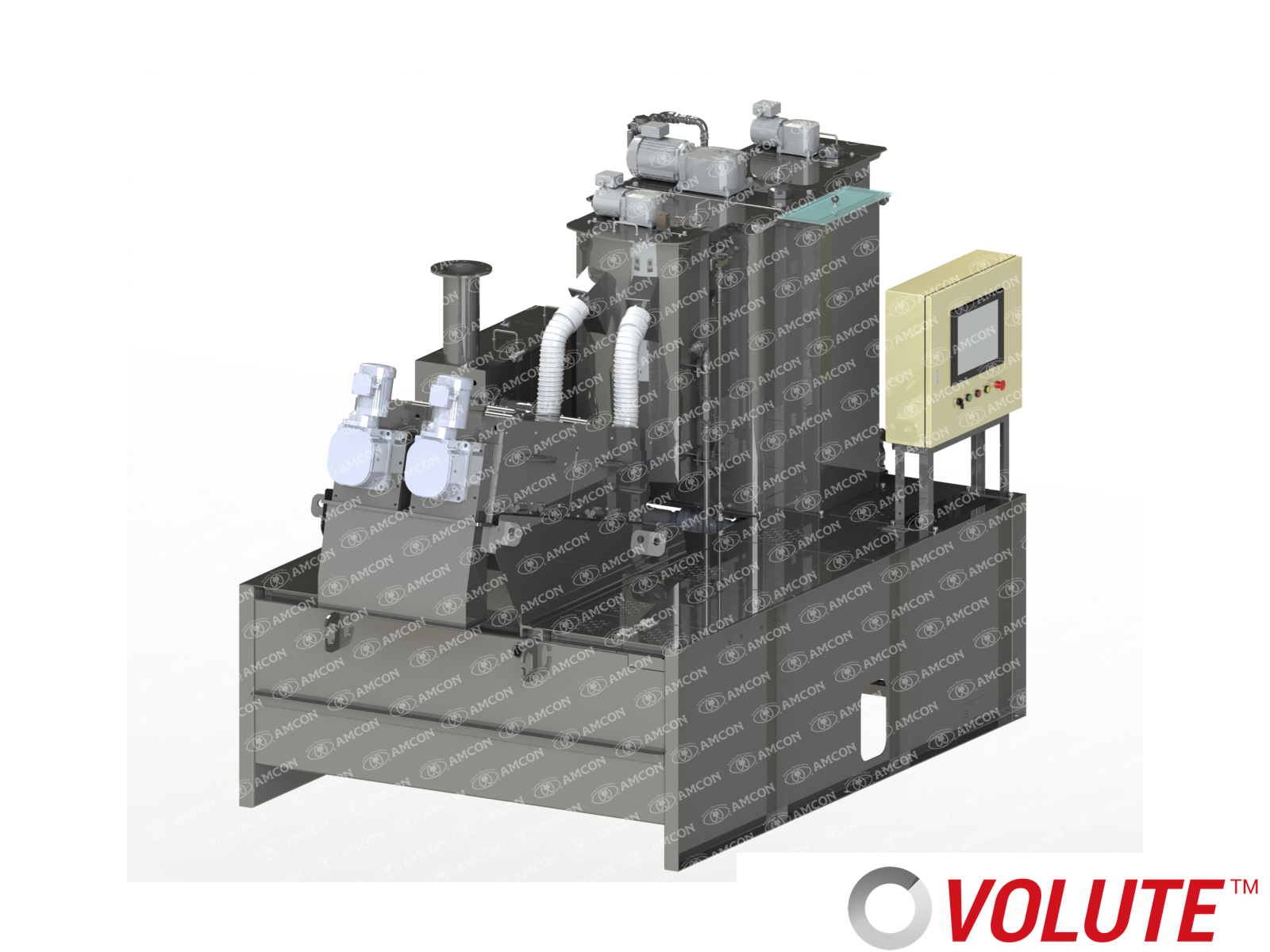

Realize stable operation with control responding to concentration fluctuation

In the treatment of mixed raw sludge, sludge properties such as sludge concentration and fibrous materials and those of seasonal sludge properties fluctuate greatly, which sometimes makes it difficult to adjust the operation of the sludge dewatering press, such as the amount of sludge fed and the amount of chemicals dosed.

In the DW series, a level sensor detects water level fluctuations in the flocculation tank, and even when the concentration of the sludge fed into the sludge dewatering press fluctuates (TS of 2.5 to 3.8%), the system automatically adjusts the amount of sludge fed into the filter to maintain that an amount of solids fed into the filter element is constant. This allows the operation with constant water content and filtration speed without changing the operation settings each time the concentration changes.

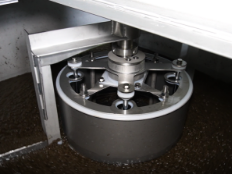

Maintainability improved

A newly designed ring is employed to remove sludge without pulling the screw out of the machine, even in the event of a malfunction such as sludge clogging inside the machine.

This reduces the time required to restore operation and shut down the sludge dewatering press.

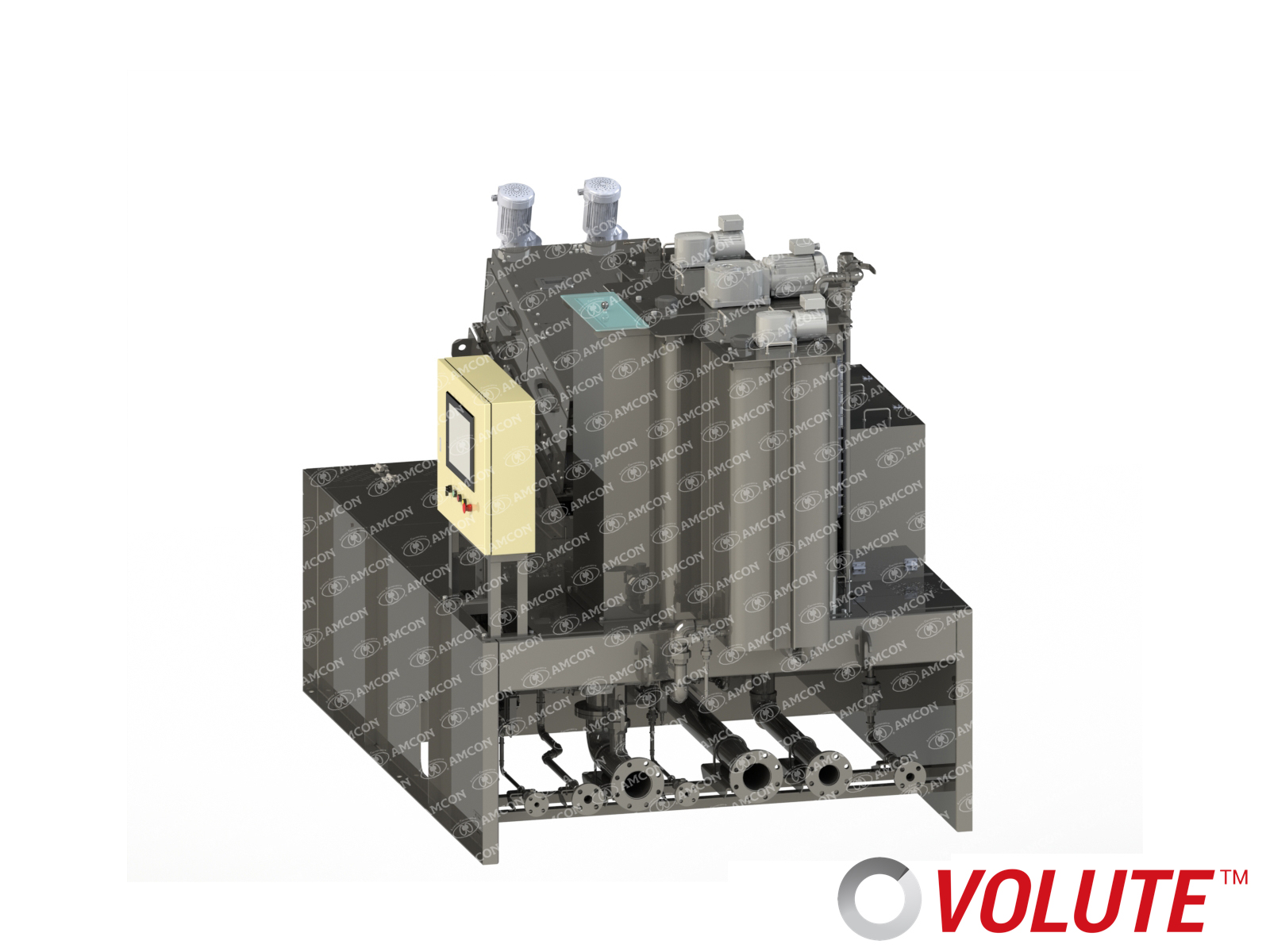

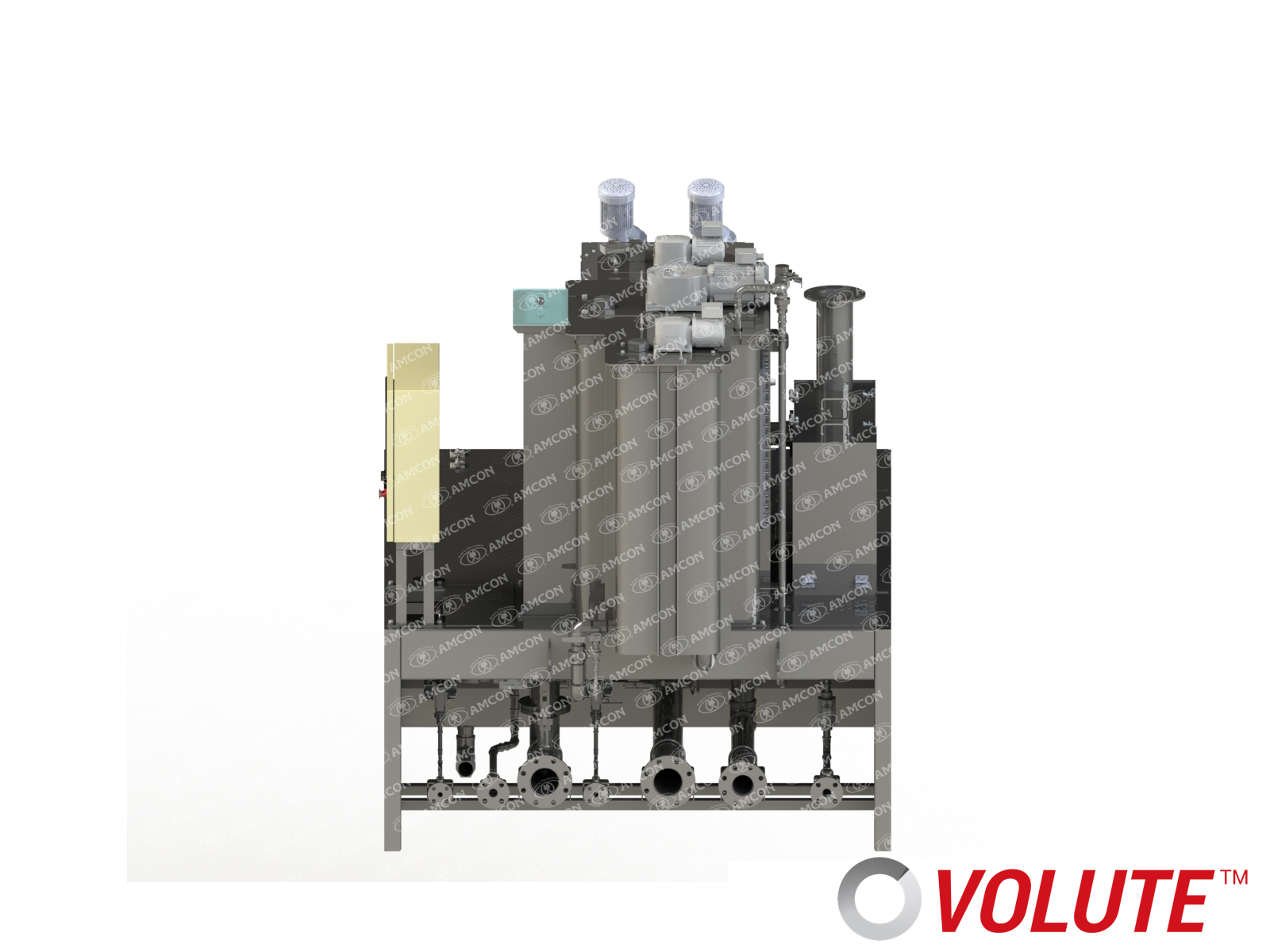

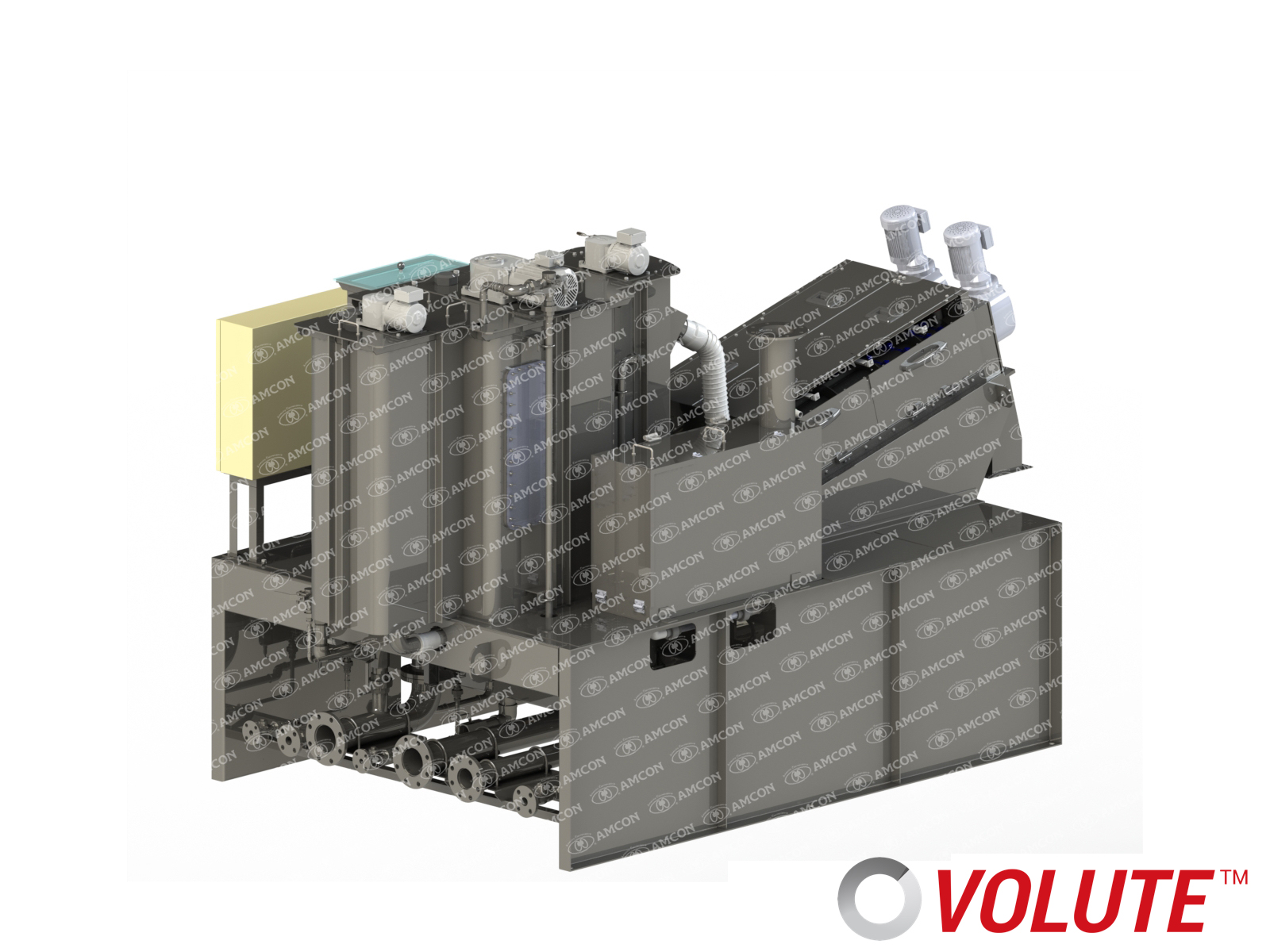

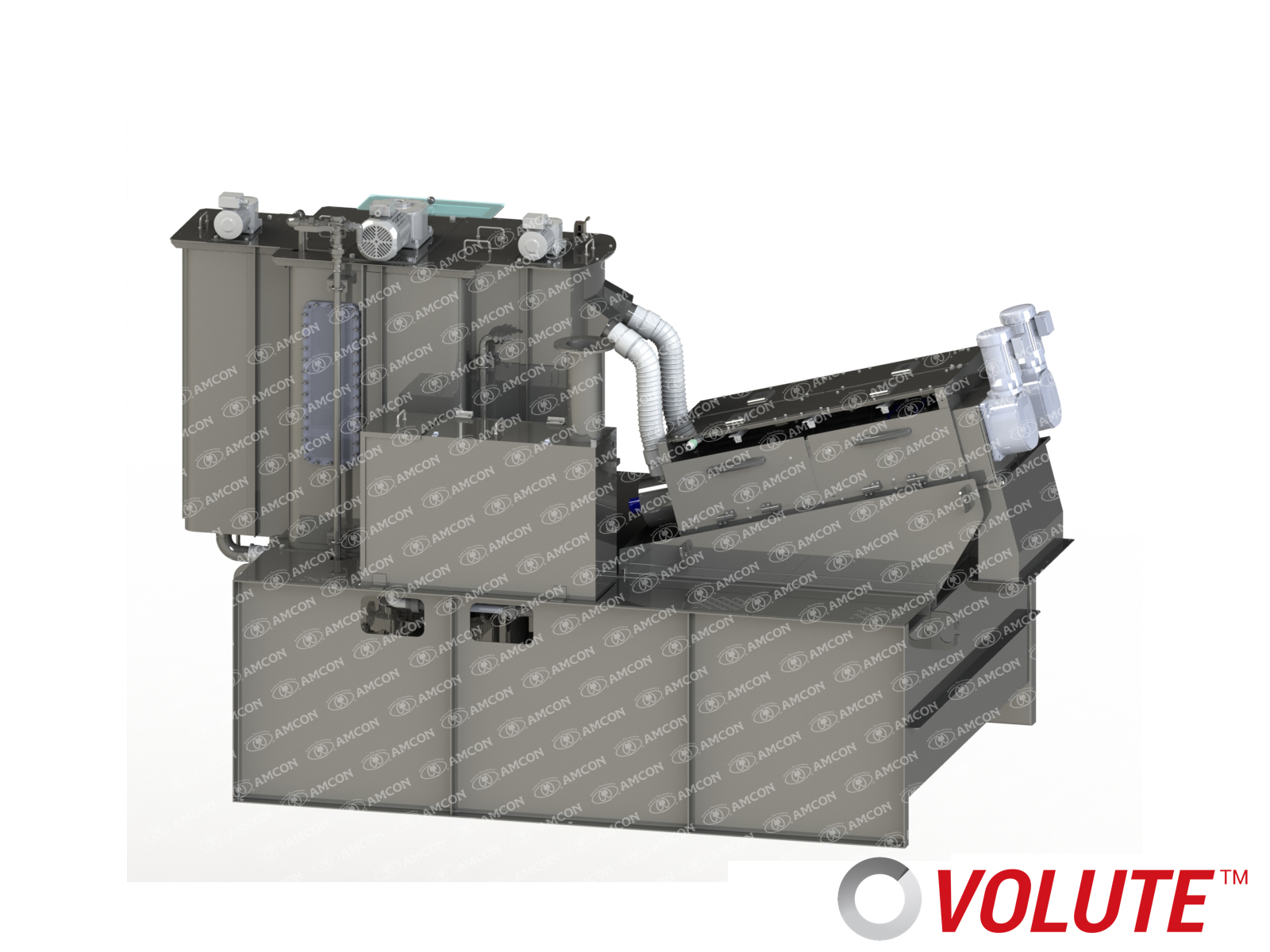

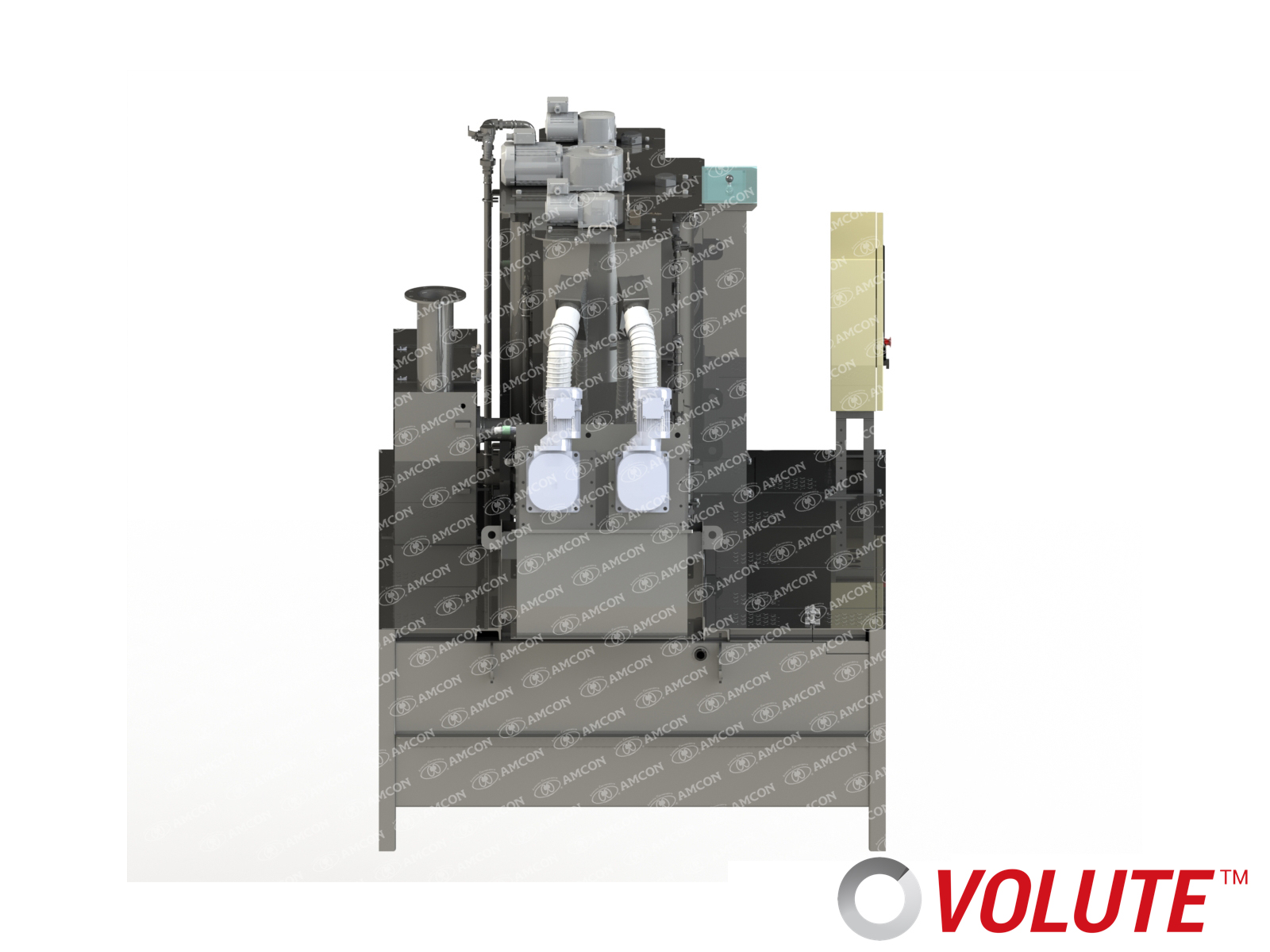

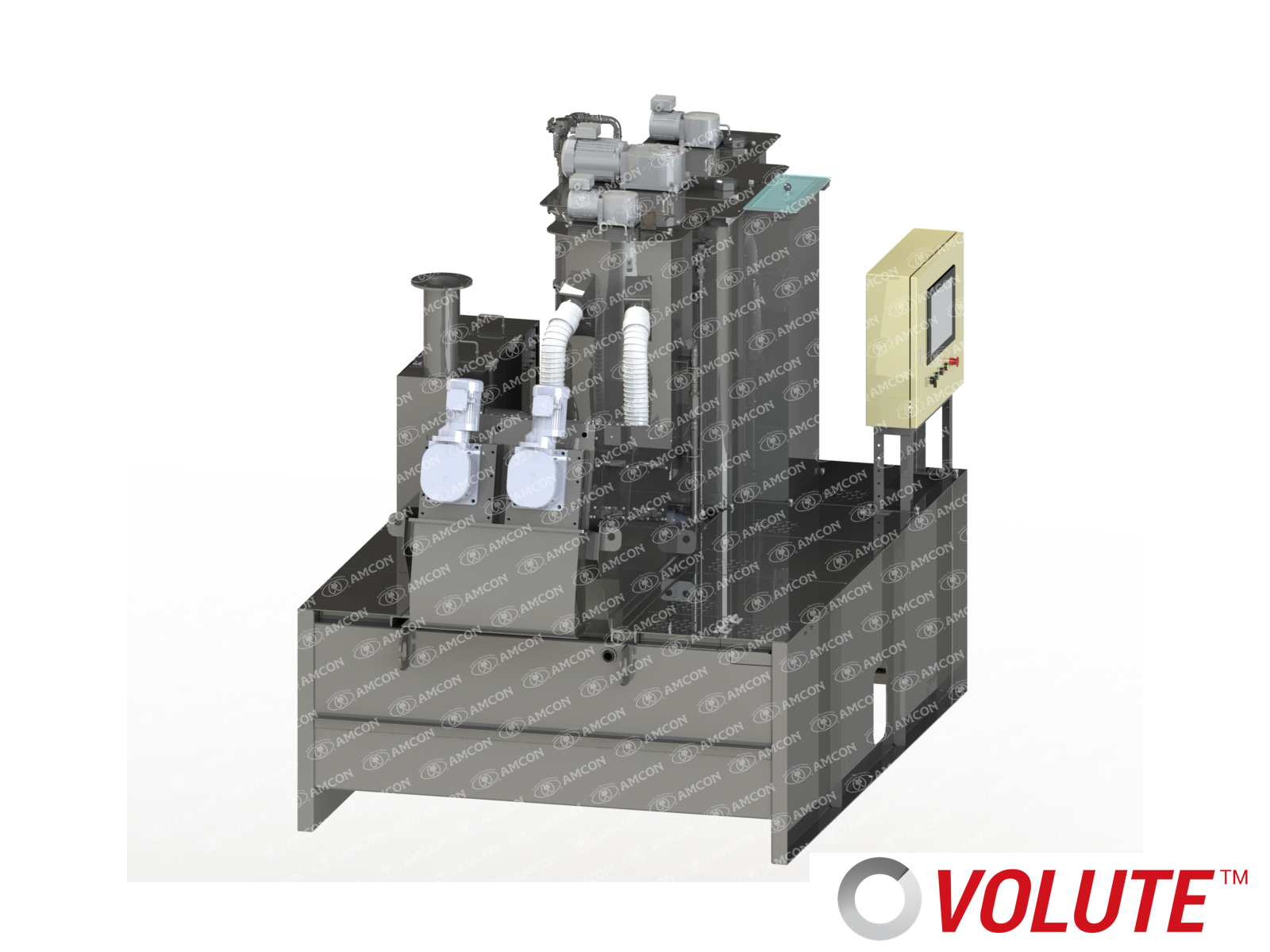

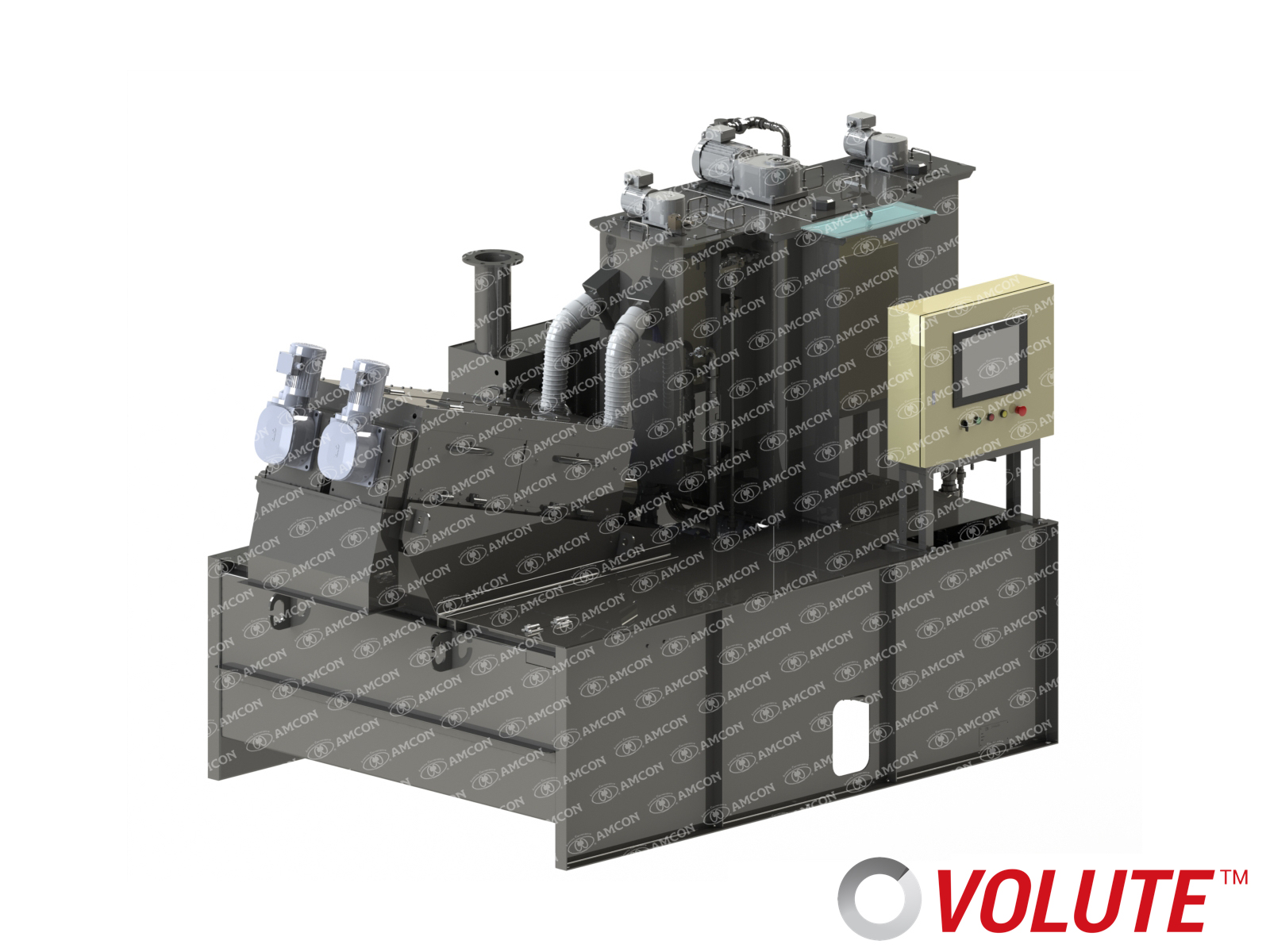

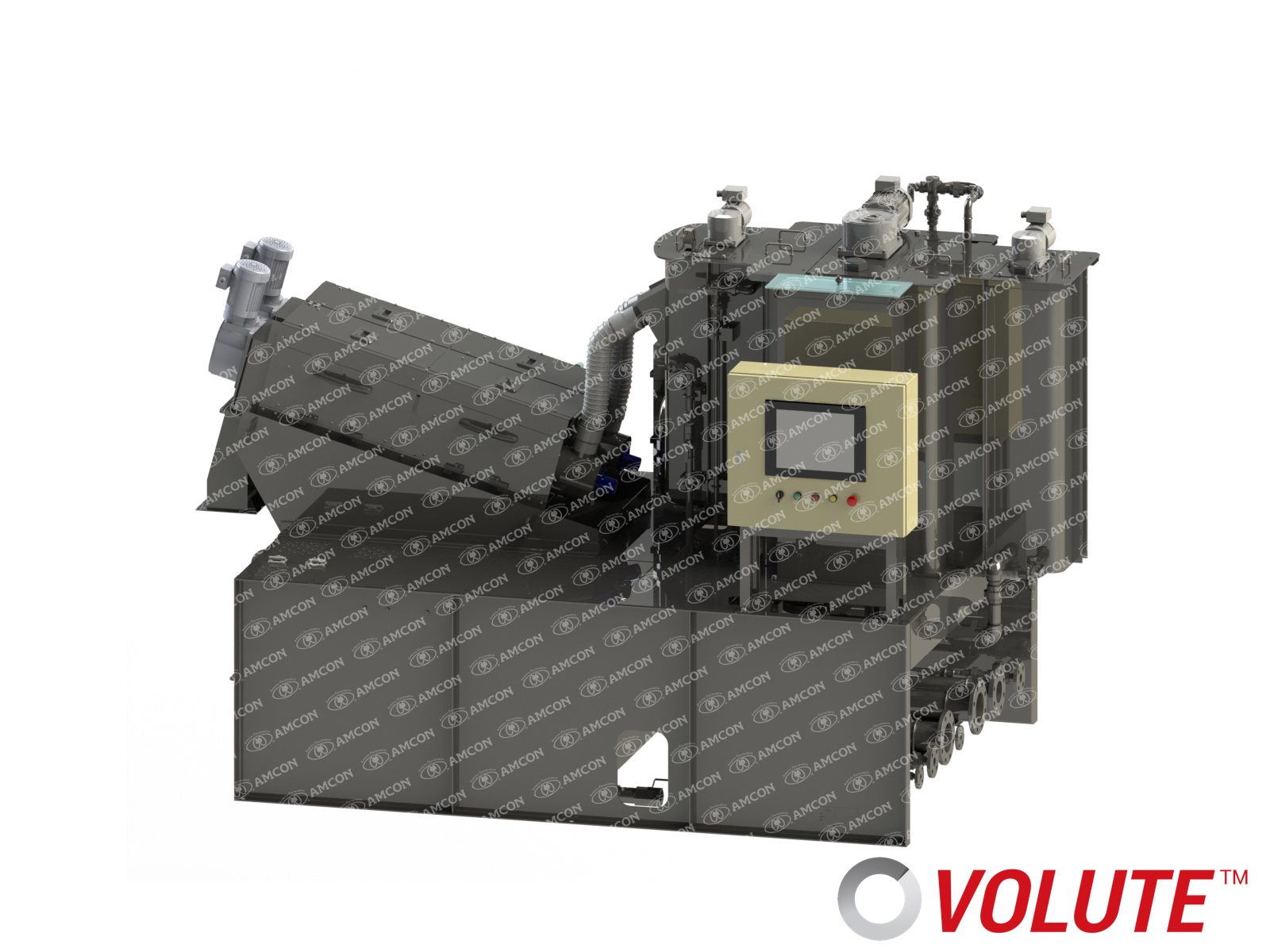

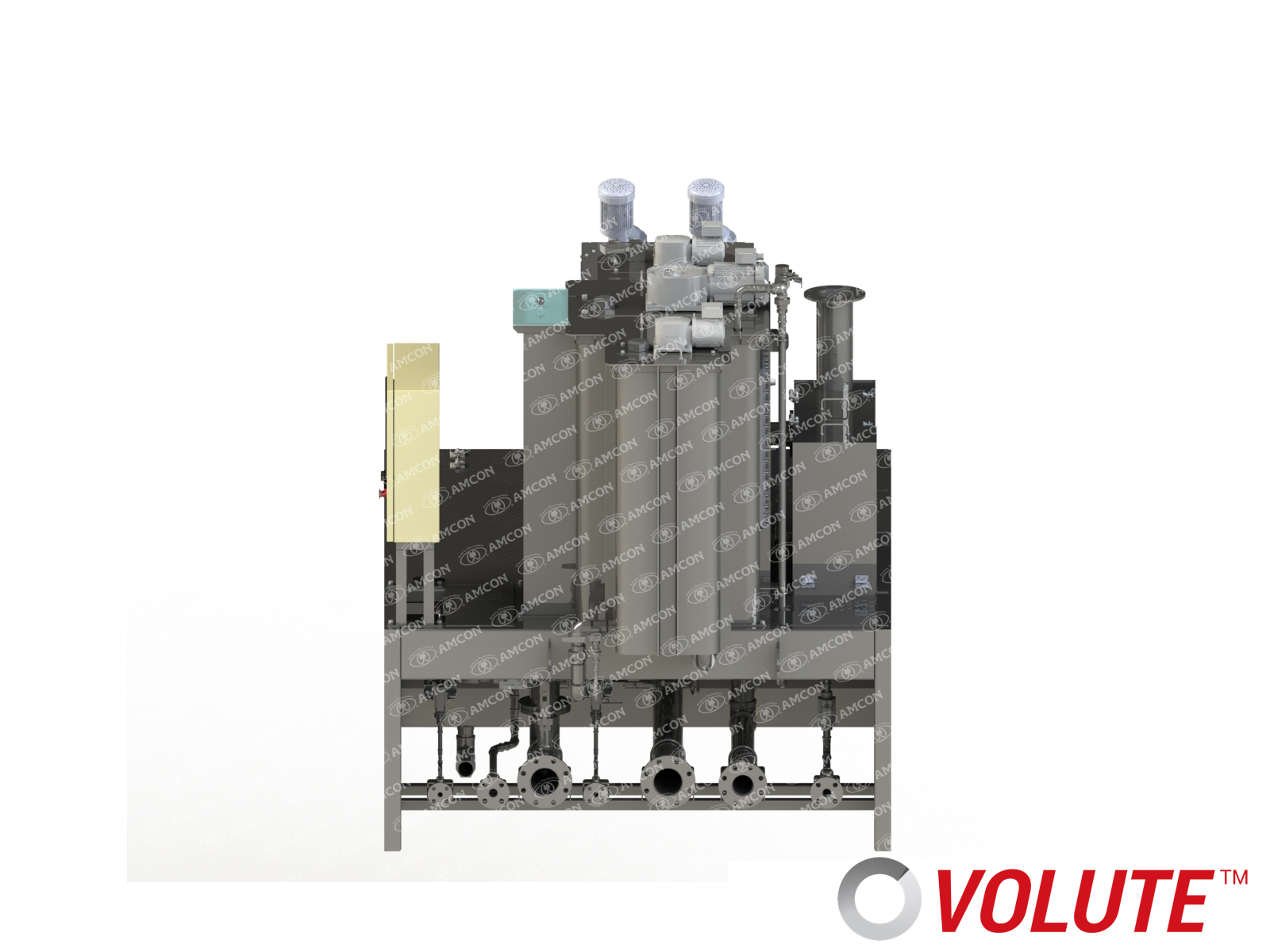

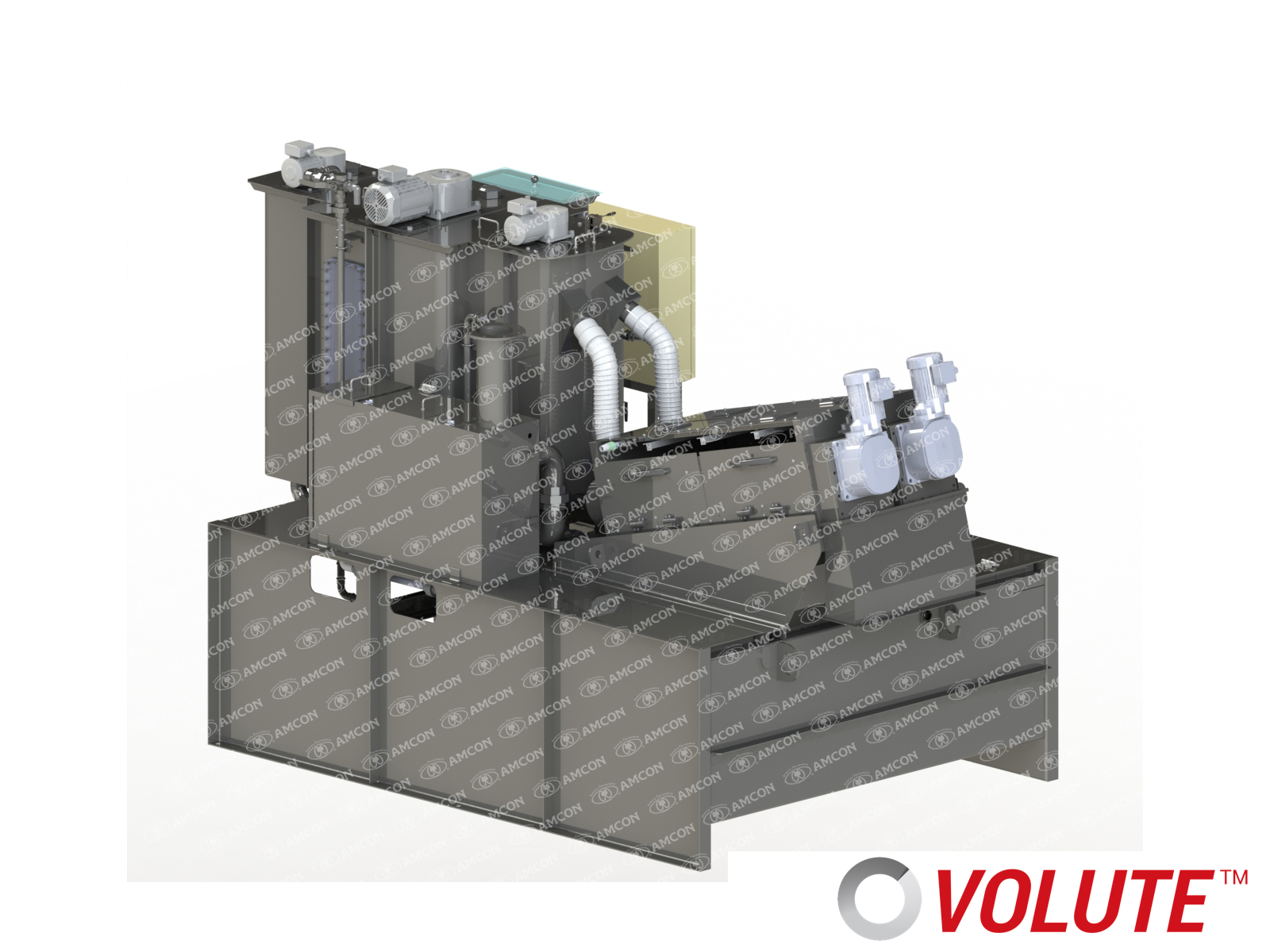

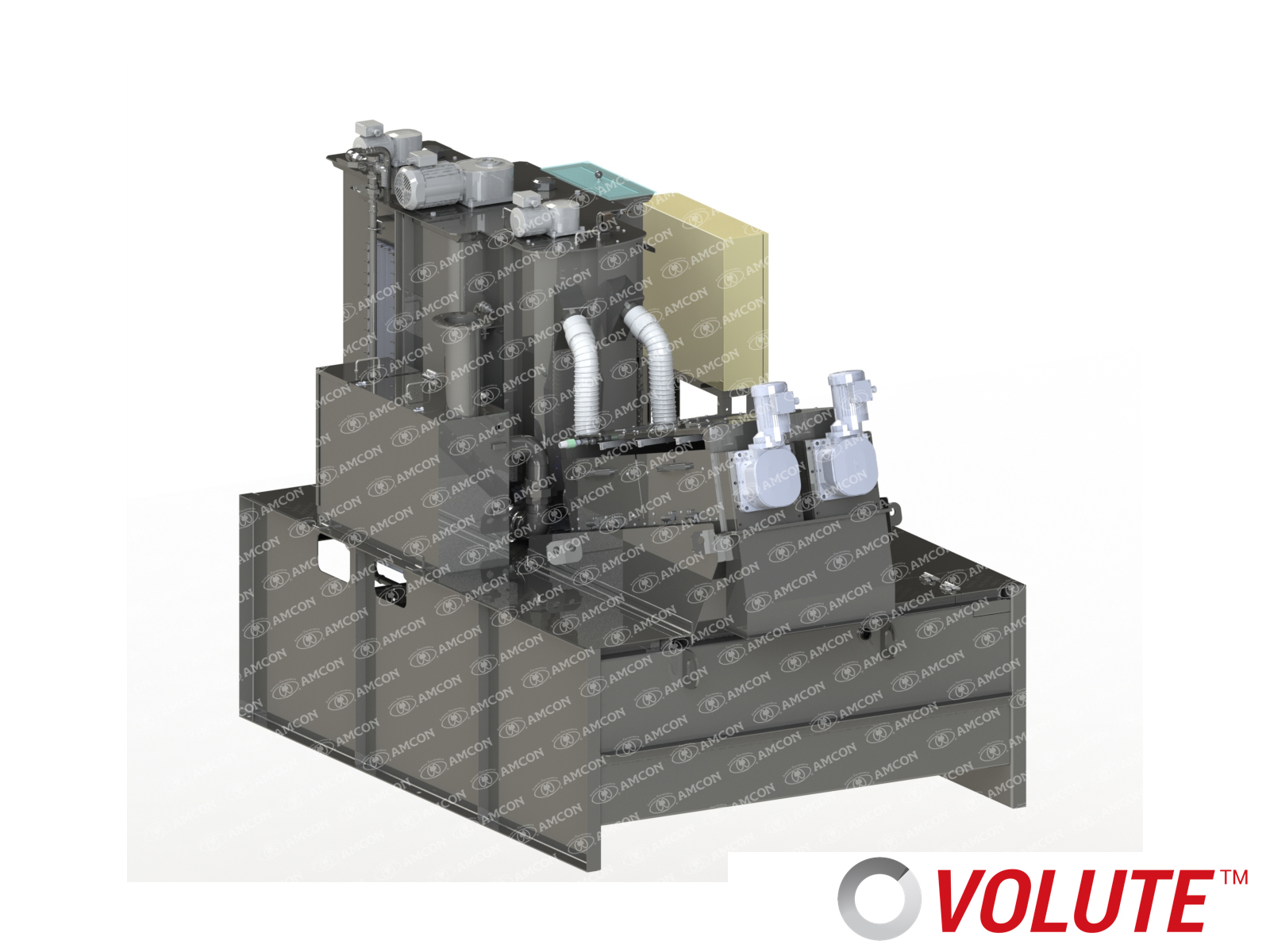

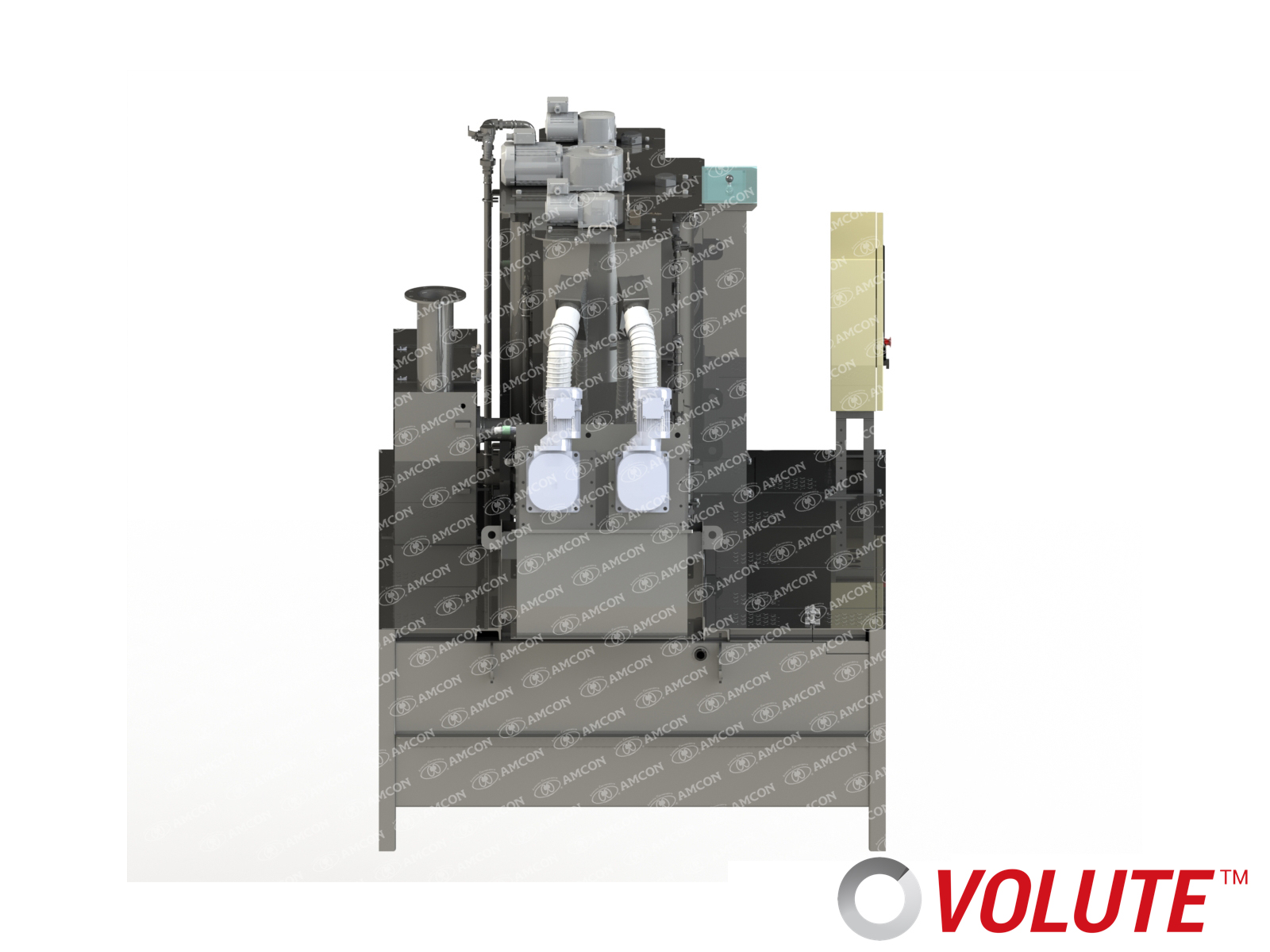

PROCESS FLOW

-

01

Automatic Screen

The screen removes the impurities such as hair, plastic, and others which are contained in the sludge. -

02

Sludge Conditioning Tank

A sludge conditioning tank temporarily stores sludge before it is dewatered. The model with a sludge conditioning tank realizes a high solid capture rate higher than 95%. When required, the conditioning tank can be used as a reactor tank for coagulant. -

03

Pre-Reactor Tank for Coagulant/Polymer

Coagulant/polymer is added to the sludge which is supplied from the Sludge Conditioning Tank, and mixed in this tank. -

04

Thickening Flocculation Tank

Polymer and sludge are stirred and mixed, forming flocs for VOLUTE™. Then, the built-in thickener in the tank instantly thicken the sludge. -

05

After-Reactor Tank for Coagulant

Coagulant added to the concentrated sludge, and mixed in this tank. -

06

Cylinder Unit

Sludge is further thickened in the thickening zone of the cylinder, and then the inner pressure increased at the dewatering zone helps sludge being dewatered well. -

07

Discharge Outlet for Dewatered Cake

Further pressure is applied from the outlet side with the End Plate, discharging dewatered cake with better than 17% dry solids content.

CASE STUDIES / TESTIMONIALS

RENTAL

Flow for Product Installation