From REVOLUTION

to EVOLUTION

A New Stage

in Sludge Dewatering

Sludge Treatment Equipment/Water Treatment Chemicals

Sludge dewatering presses, sludge thickeners, sludge dryer, water treatment chemicals, etc.

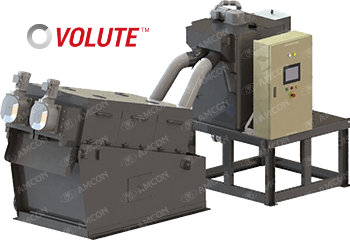

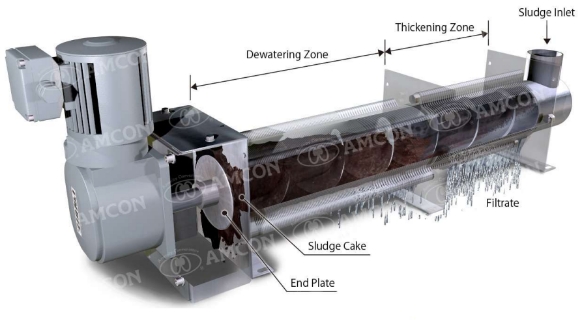

With our proprietary technology – VOLUTE DUO™/VOLUTE™ – our Japanese-made sludge dewatering presses free from clogging even with oily sludge, we can provide easy operation and maintenance through the use of unique technology which contributes to reduced energy requirements in sludge treatment .

Product Lineup

Sludge Treatment Equipment/Water Treatment Chemicals

Products Offered Only in Japan

for Municipal Wastewater Treatment Plants

RENTAL

AMCON’s Sludge Dewatering Press Unlike Any Other

Warranty And After-sales Service